Nesting Creates a Milling Challenge

This job shop uses remaining steel stock to hold a mated pair of aircraft parts.

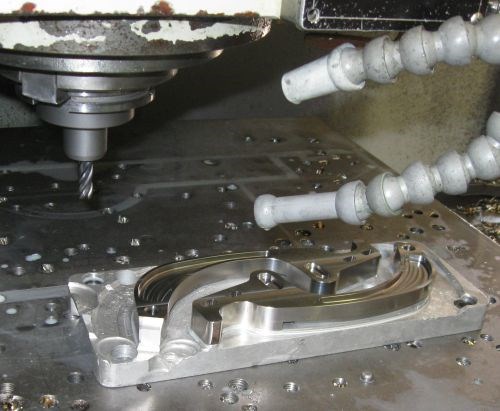

Here is side one of the nested set of parts, with a little of the shape of the parts becoming visible.

Here is side two, with the two parts rising up out of the steel block. The channel between these two parts is a difficult feature to machine efficiently.

Related Content

-

Grooving Attachment Streamlines Operation by 75%

A grooving attachment enabled Keselowski Advanced Manufacturing to reduce cycle times by over 45 minutes on a high-value, high-nickel part feature.

-

Choosing Your Carbide Grade: A Guide

Without an international standard for designating carbide grades or application ranges, users must rely on relative judgments and background knowledge for success.

-

Widia Introduces Solid End Mill for Shoulder and Side Milling

The WCE solid end milling series features a five-flute geometry specifically designed for optimal performance when shoulder milling and side milling carbon, stainless steel and cast iron.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)