Trumpf Inc.

111 Hyde Rd.

Farmington, CT 06032 US

860-255-6000

trumpf.com

IS THIS YOUR COMPANY?

Video Gallery

TruServices: Remote Service Agreements from TRUMPF

With the Remote Service Agreement package from TRUMPF, technical support is just a phone call away. Our technical specialists ...

3, 2, 1...GO! Shear cutting with the cordless TruTool S 114 🏁 #metalcutting#powertools #trumpf

Two TRUMPF Colleagues participate in a friendly competition to see who can use the TruTool S 114 cordless shear cutter the ...

Cutting with Confidence: Retrieving a Dropped Part

When you accidentally drop a part, don't waste any time trying to retrieve it. Simply select the "conveyor in reverse" function on ...

TRUMPF Services: Bending round bars with adapted stop systems

When bending round rods, the tools are provided with specially designed notches which help the operator with the insertion and ...

As Seen On Modern Machine Shop

Trumpf Inc. Supplies the Following Products

Trade Names Offered by Trumpf Inc.

- TruMark

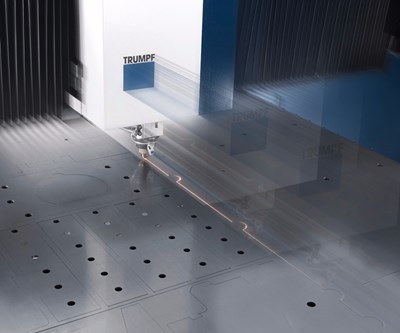

- TruLaser

- TruBend

- TruPunch

- TRUMPF

- TruMatic

- TruPrint