Five-Axis CNC Machining Centers

Besides the linear axes X, Y and Z, 5 Axis Machining Centers also move in two rotary axes, often identified as A and B axis. The rotary axes tilt the tool with respect to the part. Physically, it can be either the tool that tilts or the part that tilts. True 5 axis CNC machining uses these axes to smoothly follow a contoured surface. This type of machining has long been important in the aerospace industry, where machined parts follow the aerodynamic forms of aircraft. Some machines move the rotary axes only to position the tool or work outside of the cut. A machine capable of this “3+2” machining often can reach all of the machined features of the part in a single setup.

ESSENTIAL READING

VIEW ALL6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreChoosing a Five-Axis Machine Tool With Automation in Mind

While much focus is placed on the machinery that moves parts, the features most important for automating five-axis machining are arguably found in the machine tool itself.

Read MoreMachining 101: What is Five-Axis Machining?

Five-axis machining offers increased productivity and geometric flexibility, but the additional axes of motion can compromise rigidity and accuracy.

Read MoreWhy Was CNC Machining on Display at the Biggest Show for Additive Manufacturing?

Machining is a complement to AM as a means of finishing metal 3D printed parts. The increasing adoption of AM for production means more need for postprocessing, particularly machining.

Read MoreUnderstanding Circle-Segment Milling Tools

The circle-segment cutter represents a class of milling tool in which the CAM software is key for using the tool effectively. Cutting profiles presented at the proper angles realize cycle-time reductions in contoured workpieces such as molds. A CAM company engineer discusses the role of this tooling.

Read MoreBuying a Five-Axis: Picking Options and Add-Ons

So you’ve settled on a five-axis machine. So what options do you choose? One to remember: spindle probing.

Read MoreLatest Five-Axis News And Updates

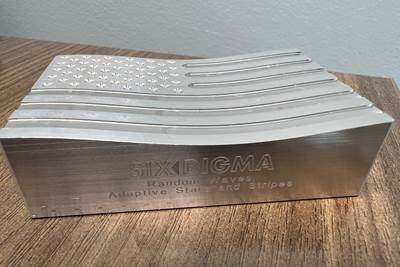

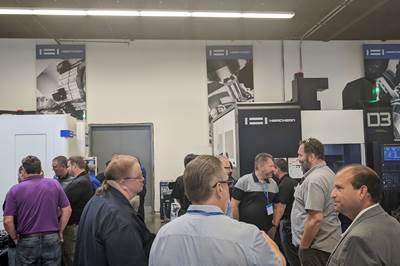

Hermle Event Encourages, Educates on Five-Axis Machining

Hermle’s first Five-Axis Summit was designed to show beginners the benefits of five-axis machining and demonstrated how more advanced users can take their capabilities to the next level with automation.

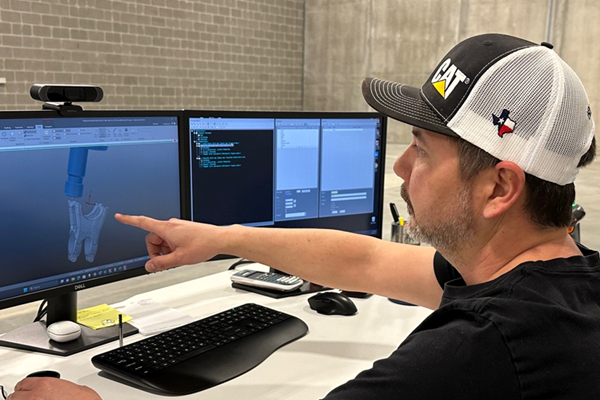

Read MoreQ&A: How a Self-Taught Machinist Started His Own Business

This machinist found an opportunity in a niche market and decided to learn machining and create his own business. Here's how he did it.

Read MoreWhich Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

Read MoreBuilding Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

WatchCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreOpen House Showcases Five-Axis Capabilities, Digital Tools

Five-axis machining technology was the highlight of the Hwacheon open house in Lincolnshire, Illinois this August.

Read MoreFeatured Posts

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreInverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

Read MoreEDM, Laser Micromachining and More at GF Medical Demo Center

At GF’s Medical Center of Competence, the company shows off EDM and laser features that could make a large impact on medical manufacturing — and elsewhere.

Read MoreDoes a Five-Axis Machine Increase Business?

Five-axis machining is enabling custom fabricator Meyer Tool to take on more complex work and helping it produce less complex jobs more efficiently.

Read MoreInvesting in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

Read MoreFearless Five-Axis Programming Fosters Shop Growth

Reinvestment in automation has spurred KCS Advanced Machining Service’s growth from prototyping to low-and mid-volume parts. The key to its success? A young staff of talented programmers.

Read MoreFAQ: Five-Axis

What is a five-axis CNC machine?

Five-axis machining adds rotational movement to the traditional three axes of linear motion (X, Y and Z). These machines can incorporate an A-axis that handles rotation of the X-axis, a B-axis that does the same for the Y-axis, or a C-axis that rotates about the Z-axis. Some employ rotary, tilting tables, which provide mechanical and thermal stability alongside improved access for swarf removal. Others employ a pivoting spindle head to accommodate larger, pallet-loaded parts.

What are the five axes of machining?

Besides the linear axes X, Y and Z, 5-Axis Machining Centers also move in two rotary axes, often identified as A and B axis. The rotary axes tilt the tool with respect to the part. Physically, it can be either the tool that tilts or the part that tilts.

What are the benefits of five-axis machining?

Granting users access to five sides of a part in a single setup enables tighter tolerances. Parts with 3D contoured surfaces (such as mold cavities and electrodes) tend to be great candidates for five-axis machining. For example, flexibility in accessing deep cavities enables shops to use tool assemblies with reduced lengths and aspect ratios for these operations.

Improved tool orientation control also helps with tool breakage and chatter when working with difficult-to-machine materials. For example, the surface speed of a ball mill depends on the contact angle between tool and surface. On three-axis equipment, this angle changes as machining proceeds. When the bottom of the ball mill contacts the part, surface speed becomes an unproductive zero. Surface speed then reaches its peak when the tool’s equator contacts the part. These variations in surface speed cause variations in surface finish, create premature and unpredictable tool wear, and reduce productivity.

Active orientation enables five-axis contouring: the angle of the tool changes relative to the machine axes in real time. This enables a constant angle and surface speed, leading to higher programmed feed rates and better surface finishes.

Orientation control also boosts performance of flat-bottom and bull-nose end mills that need a constant 5- or 10-degree angle between the cutter axis and the plane normal to both the surface tangent plane and the direction-of-motion plane. The angle increases the effective radius, reducing the scallop height, improving surface finish and reducing the number of tool passes required to complete the operation. Controlling tool orientation also enables a constant depth-of-cut and accounts for variations in the stock-on condition of parts.

What are the drawbacks of five-axis machining?

Five-axis functionality comes with a learning curve — shops adopting five-axis for the first time cannot expect plug-and-play success. Machining strategies will require reconfiguring tailored to the specific part family under production. The machine, the CNC and the CAM software are likely to be more expensive than comparable three-axis versions. Additional axes of motion introduce additional sources of error and potentially compromise rigidity. In short, five-axis is a high-yield process, but it is also higher-risk.

Initially operating a five-axis machine like a three-axis machine may seem like a waste of capability, but it can help users become more familiar with the machine while they learn.

What are some common types of five-axis machines?

Compound rotary tables are the most straightforward and economic way of getting five-axis performance, but they come with several significant drawbacks. These tables can be added to three-axis machine tools, but are less stiff and possess higher angular errors than more integrated approaches. Stacking the rotary axes on top of each other further magnifies angular errors, and the large stack-up between workpiece and rotary axes with a double-tilt rotary means high-torque loads affect the gear sets, reducing life and increasing deflection.

Two-axis spindle heads, also called spindle heads, typically see use on gantry-type machining centers. They suffer the same accuracy and stiffness weaknesses as double-tilt rotary tables, and can have limited rotational range (for vertical machining, the C-axis will typically have an unlimited range of motion, while the A-axis might be limited to ±90 degrees of motion from the vertical position).

Single-axis spindle heads, often called “pendulum-type” heads, generally provide better accuracy than double-tilt tables or multi-axis spindle heads because the rotary axes are not stacked.

The tilting spindle, when combined with a single-axis rotary table, is generally the best choice for five-axis machining of small- to mid-size concave and convex components. Prismatic and long, slender parts are particularly well-suited for this configuration. The B-axis enables the spindle to rotate around the tool tip, minimizing angular errors and keeping torsional loads on the B-axis to a minimum.

Further reading: Machining 101: What is Five-Axis Machining?

.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)