Workholding

Welding, Assembly Clamps Useful in Automotive, Aircraft Industries

Destaco has launched its TCC-2E series of tolerance compensation clamps (TCCs) designed to provide greater flexibility in welding and assembly applications that require the clamping of components of differing thicknesses or tighter tolerances.

Read MoreAir Rest Buttons Detect Proper Workpiece Loading

Carr Lane’s air rest buttons enable the use of pneumatic position control to detect proper workpiece loading in a machining fixture.

Read MoreFive Live Centers for Five Applications

It is vital for a shop to select the right machine tool components for the right job, and live centers for lathes are no exception.

Read MoreJaw Nuts Minimize Jaw Change Time

Dillon Fast-Trac jaw nuts are designed to convert standard chucks into quick-change chucks, reducing jaw change time by as much as half.

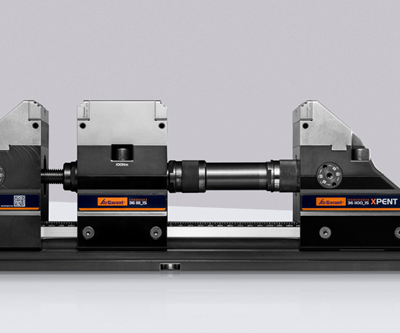

Read MoreModular Vise Clamps Two Workpieces

The Hoffmann Group has released a module for its Garant Xpent five-axis vise.

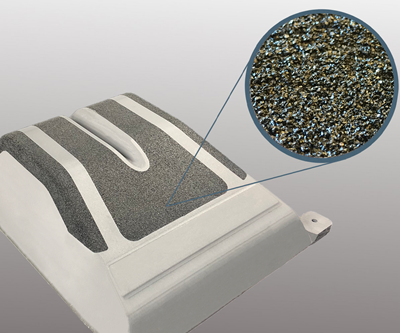

Read MoreWorkholding System Increases Vacuum Surface Area for Mill Fixtures

Technical Tooling’s Vacu-Grip composite workholding system vacuums mill fixtures by using a granular media technology that configures to any complex three-dimensional shape.

Read MoreRöhm Acquires Master WorkHolding

Master WorkHolding will serve as Röhm’s North American manufacturing entity and provide the company with prismatic clamping fixtures.

Read MoreWorkholding Enables Stress-Relief Reclamping

IMTS 2018: The Schunk Vero-S Aviation product line is designed to rigidly clamp large parts accurately and enable the user to release the part enough to allow the part to move (compensate) due to the stresses of machining without fully releasing the part.

Read MoreFixturing Components Improve Range of Applications

IMTS 2018: Fixtureworks offers a lineup of bearing wheels, indexing plungers and TG GripSert inserts.

Read MoreKitagawa NorthTech Now Distributor for Nobel Chucks

Kitagawa NorthTech earlier this year absorbed Itex Workholding operations, which previously held the distribution rights for Kawatatec Nobel Chucks in North America.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)