A Micro Machine Design

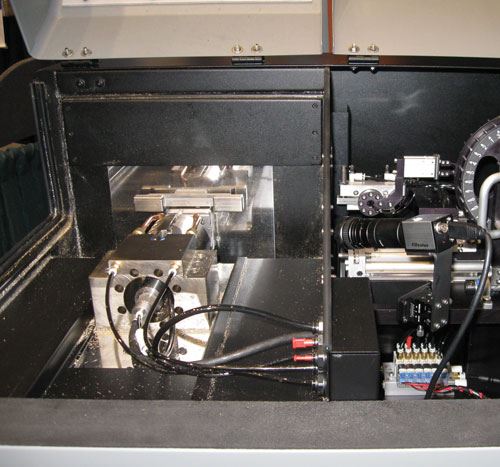

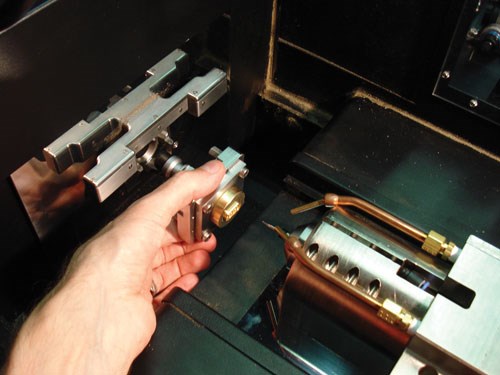

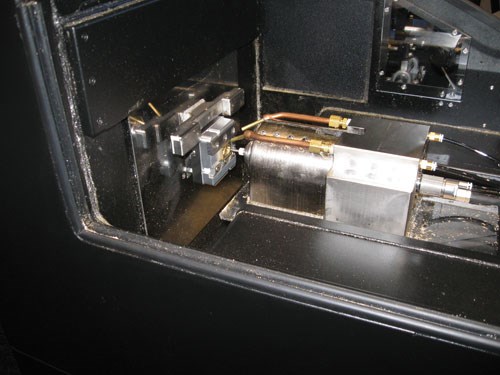

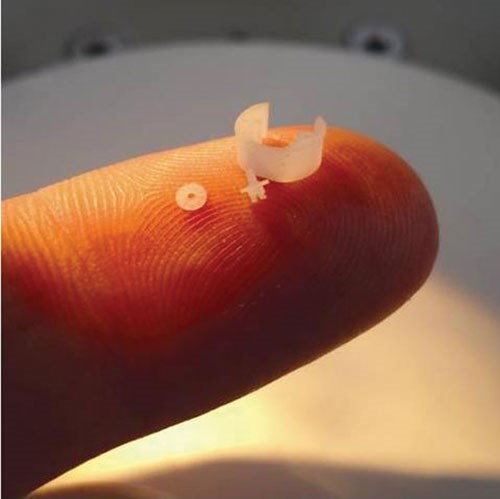

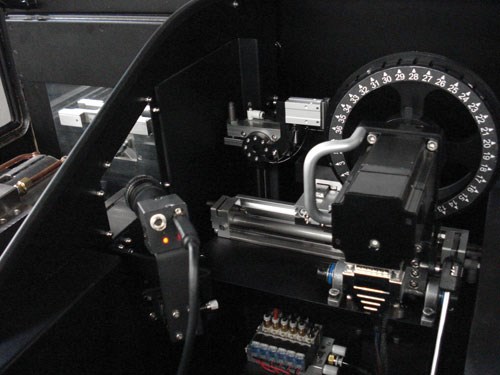

This machine has no toolholders and no tombstone—but there is a camera. Here are details of a machining center designed for micromachining.

A full-size, high-performance machining center is capable of micromachining, but is it necessary for micromachining?

Microlution’s 363-S machining center was designed around the premise that if the machine tool does only tiny work, then the travels of a full-size machine are not needed. On this machining center, travels are just 2.48 inches in each of the three axes.

The machine is also limited to small tools. The spindle does not accept cutters with shank size larger than 1/8 inch.

However, one result of these size limitations is that the company was able to design a precision machining center within a very small footprint. The machine occupies only a 2-foot by 2-foot area of floorspace.

Microlution vice president Andrew Honegger says this footprint can bring machining capability to settings where machine tools otherwise wouldn’t be considered. One example is a product development laboratory, he says. Placing the machine here could allow the machining process for a new micro-component to be developed along with the component itself—so both the part and the process are proven out together.

The design of this small machine is unusual enough that it merits a brief tour. Click on the photos at right to see some of the design features that separate it from high-performance machining centers based on standard designs.

Related Content

-

JTEKT Launches New Series of HMCs

The new FH5000 series machines include a 500-mm table capable of handling 1,000-kg loads.

-

The Job Shop Is the First Half of the Business

By day, NTL Industries went from a lathe and a mill in a home garage to an 11-employee enterprise in under five years. By night, it tackles a new future.

-

Horizontal Turning Center Ready for High Production

Romi Machine Tools’ new GL300 S features high-power torque and feed force and is built with a robust monoblock base for ultimate rigidity and precision.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)