August 2005 Issue

August 2005

Features

Featured articles from the August 2005 issue of Modern Machine Shop

Get Lean, Go Global

A successful manufacturing company must achieve world-class capability within its walls. At the same time, a company has to go after global business opportunities. Hanel Corporation (New Berlin, Wisconsin) is a case in point. It has implemented several U-shaped production cells that help the company keep costs down and productivity up. At the same time, company leaders have aggressively courted customers in countries around the world by offering both tangible and intangible values.

Read More

Making A Flexible Machine Tool More Flexible

Multitasking cutting tools can maximize the flexibility of multitasking machines.

Read More

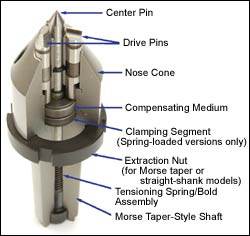

Selecting High Speed Tooling Requires A Balanced Approach

Plug in the right choices, use the right formulas and repeatability, reliability and improved productivity result.

Read MoreWhen Disaster Strikes

If your equipment was damaged or destroyed by flood or fire, would you know what to do?

Read More