Ballnose Alternative Shines in Five-Axis Finishing

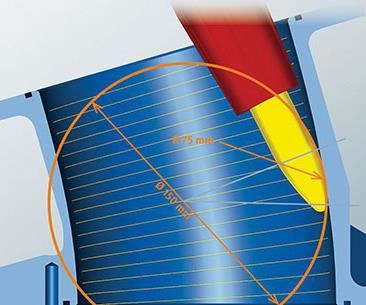

Large cutting edge radii facilitate higher-stepover passes that improve surface finish and reduce cycle time.

This promotional video from Emuge-Franken demonstrates the Top-Cut line of circle segment end mills in action on a worm-wheel component.

The ballnose end mill has some new competition. Recent collaboration between a CAM software developer and a cutting tool manufacturer in Germany has been focused on different geometries that they claim can be even more effective in five-axis semi-finishing and finishing, particularly on the planar and ruled surfaces common to moldmaking and aerospace applications. Named for their extreme cutting edge radii, circle-segment end mills are designed for sweeping, high-stepover passes that cleave wide swaths of material to maximize efficiency and minimize cusps.

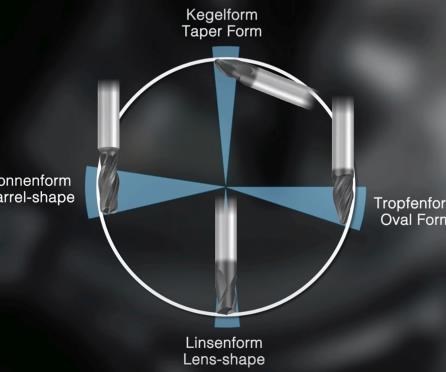

Some manufacturers may already be familiar with tools that operate in this way, which are typically called barrel cutters. Long recognizing the potential of barrel geometries, CAM software developer Open Mind Technologies has supported them in its HyperMill system since 2002. More recently, however, the company began experimenting with a variation on this design: a conical barrel cutter that tapers at the tip between 20 and 40 degrees to facilitate a shorter shank—and greater five-axis rigidity—than would otherwise be possible. Thanks to a partnership with cutting tool manufacturer Emuge-Franken, that concept is now reality. Available in North America from Emuge Corp., the taper form end mill is one of four circle-segment geometries produced not as specials, but as a standard catalog items in the Top-Cut line of end mills.

According to Open Mind, HyperMill is the only CAM system so far to offer full support for the taper form (conical barrel) end mill, which is said to achieve stepdown distances as much as 20 times greater than those of a comparable ballnose. The software also features a dedicated finishing strategy for using it on planar (flat) surfaces. Released with the latest version of the software last fall, Tangent Plane Machining (TPM) is a Z-level finishing routine designed to ensure programmers don’t spend any time strategizing about toolpath specifics and manually plotting curves. Rather, they can choose surfaces and boundaries and let the CAM system automatically calculate approach, retract and machining angles while accounting for potential collisions, just as it would for a ballnose tool. TPM also helps ensure an optimal machining strategy, which can be particularly advantageous for repeat work. Presented with a large pocket, for instance, the software might output 3+2 tool paths that limit wasted motion by machining section by section, with the spindle locked at a set angle for each portion of the cavity and rotating only as necessary to avoid interference. The developer says the next version of HyperMill will extend support to ruled and other gently arched surfaces.

Open Mind and Emuge didn’t stop with the taper form. Other circle-segment geometries in the Top-Cut line include a lens shape as well as relatively more traditional oval and barrel shapes, which benefit from broader CAM software support. Images on this page and the next illustrate why both companies are confident that the industry has much to gain from wider availability and greater support for multiple types of extreme-radii end mills. All four circle-segment geometries operate according to the same basic principle: Greater contact between cutter and work enables removing more material with fewer passes. That translates to fewer tools, shorter machining cycles and smoother surface finishes, all without the need to wait for custom cutters that can’t be seamlessly incorporated into part programs.

Of course, a tool designed to perform at greater axial depths than even the largest ballnose end mill must also withstand greater forces, particularly in difficult materials like titanium and Inconel. That requires a stable, highly dynamic five-axis machining center. Testing in Germany was conducted on a Hermle C32 U, which used all four Top-Cut circle-segment geometries in a series of 14 operations to machine a worm-wheel component from steel 1.2312 (see the video above). According to Emuge, circle-segment geometries achieved Ra surface finish of 0.57 micron on this part, whereas conventional end mills managed only 1.15 microns. On a different test part, circle-segment tools reportedly reduced cycle time for a flat-face finishing operation from about 40 minutes to only seven.

Determining which of the four Top-Cut circle-segment tools to use is a simple matter of comparing how the edge matches up with the geometry to be machined. The oval form, for example, can be ideal for machining the curved sides of turbine blades, and the angle at which the cutting edge extends from the shank enables engaging more of the cutting edge without interference. The even more pronounced angle of the taper form also helps ensure clearance, particularly in straight-walled pockets. The flank-cutting action of the barrel design lends itself particularly well to finishing the sides of deep spiral grooves, among other applications. In contrast, the lens form is useful for machining details perpendicular to the spindle, such as the narrow channels of a tire mold surface.

Related Content

Selecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read MoreA New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

Read MoreTwin Spindle Design Doubles Production of Small Parts

After experiencing process stalls in the finishing stage of production, Bryan Machine Service designed an air-powered twin spindle and indexable rotating base to effectively double its production of small parts.

Read MoreHow to Turn Machine Shop Downtime Into Process Expertise

To take advantage of a lull in business, JR Machine devised a week-long cutting tool event that elevated the shop’s capabilities with aerospace alloys.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)