Sky’s The Limit… Or is it?

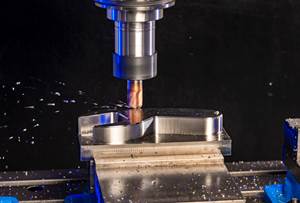

Aerospace, as an industry, gets a lot of attention every IMTS, and for good reason. Aerospace parts tend to be complex, and they often use difficult-to machine materials such as titanium and Inconel and frequently require more advanced technologies such as five-axis machining and additive manufacturing (AM).

With so much advanced technology involved in the production of aerospace parts, it is no wonder that IMTS 2022 has numerous conferences and booths that manufacturers working in the industry will find helpful.

A Confluence of Conferences

One area of the show that is rife with aerospace content is the conferences. These conferences give successful manufacturers the chance to share their experiences with IMTS visitors, providing insights into various approaches to manufacturing.

One conference to look out for is Titanium and Inconel Machining On a Grand Scale. Taking place on Wednesday in the West Building (W193-A), the event will have WFL Millturn Technologies Sales Manager John Kelly speaking on the uses of millturn machines in producing aerospace parts.

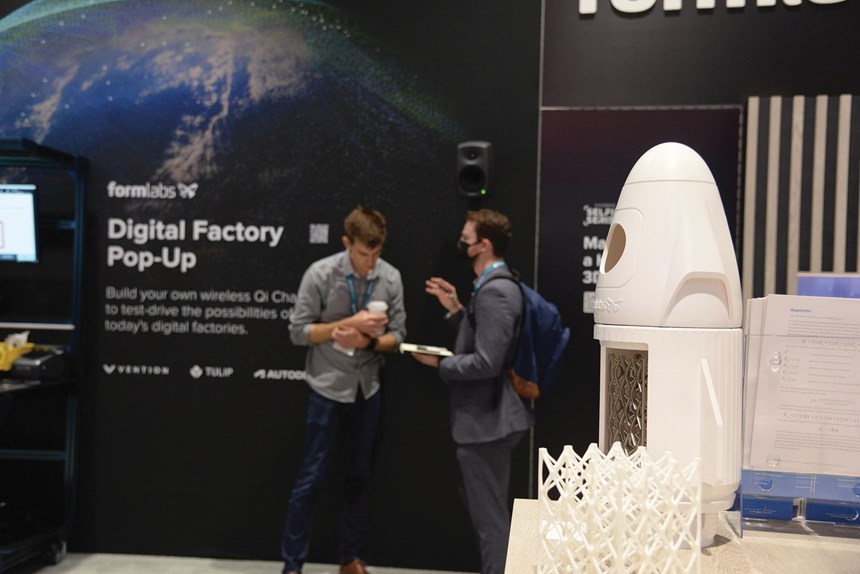

The Additive Manufacturing Conference includes numerous talks that specifically discuss the use of AM to produce aerospace parts. On Thursday, for example, the AM Conference will present a talk by Norsk Titanium called “Industrialization of Metal AM: Meeting Cost, Quality and Scheduling Expectations.” In it, Norsk CTO Carl Johnson will discuss his company’s approach to using AM to produce aerospace parts at full production levels. Find it, along with the rest of the AM Conference, in the West Ballroom in the West Building.

Other conferences cover specific challenges faced by producing certain kinds of parts, such as Next Generation in Continuous Generating Grinding of Aerospace, ICE, and EV Gears, presented by Norton Saint-Gobain Abrasives Corporate Applications Engineer Spencer Artz. This talk (taking place in the West Building W192-A) will discuss how grinding wheels are meeting the challenges posed by more difficult applications in aerospace and electric vehicle gears.

Additionally, aerospace manufacturers may find value in Layout and Planning Techniques for 5-axis Machining Centers (West Building, W193-A). As the name suggests, this conference focuses on how to develop a plan for five-axis machining in order to maximize your ROI. The speaker will be East at Jergens Technical Sales Manager Jack Rushlander, who will take visitors through a complete planning process in SolidCAM, from raw material to finished part.

Technology To Watch Out For

Of course, aerospace manufacturers have more than just conferences to see. The South Hall is where visitors can find the majority of CNC machines specializing in metal removal. For aerospace shops looking to grow, this is where you will find five-axis mills, millturn machines, multi-spindle machines, and grinding machines.

Over in the West Hall, visitors can find plenty of other companies that serve aerospace manufacturers. In addition to the tooling companies who sell specialized cutting tools for aluminum and titanium parts, this is where more additive manufacturing companies are located.

Of course, plenty of companies throughout the show have technology and expertise that is perfectly suited for aerospace applications, so be sure to explore the floor!

Related Content

Combination Lathe Enables Both Manual, CNC Operations

IMTS22: Milltronics showcases its ML16II/40 combination lathe, as well as its VM3018IL performance vertical machining center.

Read MoreIMTS 2022 Review: Attention to Automation Extends Beyond the Robot and the Machine

The advance toward increasingly automated machining can be seen in the ways tooling, workholding, gaging and integration all support unattended production. This is the area of innovation I found most compelling at the recent International Manufacturing Technology Show.

Read MoreHow is an EV Battery Made?

Everyone talks about batteries, but how are they produced? Here’s the long and short (circuit) of it.

Read MoreBall-End Tool Contours, Chamfers and Finishes in One Pass for Most Materials

The new IMCO Carbide Tool Pow•R•Arc end mill, to be shown at IMTS 2022, emphasizes speed. The cutter is able to run and increase feed rates to machine one’s mold up to five times faster than a four-flute tool.

Read MoreRead Next

Obscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)