CNC & Machine Controls

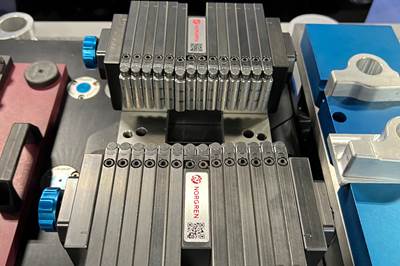

The CNC (computer numerical control) system of a machine tool includes the control unit itself, as well as the motion-control system such as the servomotors, drives and axis positioning devices. These components are part of any CNC machine tool, but they might be bought separately and retrofitted later on older machines that are upgraded or refurbished. Also part of the control system are sensors that may allow the control to make certain real-time decisions during unattended or lightly attended machining processes. These can include probes for measuring the position of the part or machined features, as well as monitoring systems for detecting the presence of the tool or the force that is being exerted in the cut.

ESSENTIAL READING

VIEW ALL6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

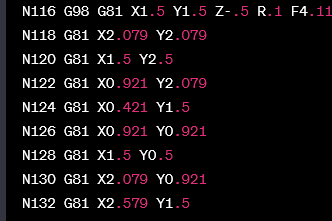

Read More7 CNC Parameters You Should Know

Parameters tell the CNC every little detail about the specific machine tool being used, and how all CNC features and functions are to be utilized.

Read More5 G-Code Tips for Increasing CNC Efficiency

Optimizing G code is a low-cost way to improve CNC efficiency without sacrificing usability and safety.

Read MoreUnderstanding G27, G28, G29 and G30

Take a closer look at these reference position commands.

Read MoreUnderstanding CNC Machine Accuracy and Repeatability

Properly evaluating machine tool capability requires understanding how the both user and the builder can influence precision.

Read MoreWhen to Use Custom Macros With a CAM System

Custom macros can offer benefits even when using a CAM system to prepare programs – but must be implemented with the right considerations.

Read MoreLatest CNC & Machine Controls News And Updates

Tips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreFrom Tradition to Transformation: Century-Old Manual Machine Shop Adds CNCs

After 122 years of working with manual mills and lathes, this fifth-generation shop acquired assets of a local CNC machining business and hired the owner. Here’s how it’s going a year later.

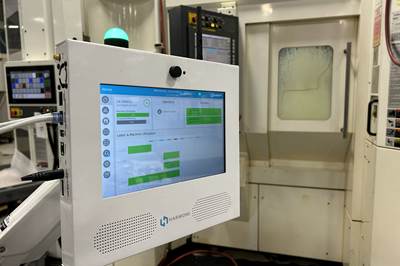

Read MoreKitamura Control System Simplifies Machine Operation

The Arumatik-Mi control offers G-code programming with built-in assistance; customizable visual work setting screens; maintenance support functions; and video guidance on a large 19" LCD.

Read MoreCNC-Related Features of Custom Macro

CNC-related features of custom macro are separated into two topics: system variables and user-defined G and M codes. This column explores both.

Read MoreComputer Programming-Related Features of Custom Macro

Custom macro is an interpreter-based language, meaning that all CNC G code and custom macro commands are executed as the CNC comes across them.

Read MoreAutomation and Process Simplification Define Eastec 2023

Manufacturing technology at this year’s Eastec met the market with tools to streamline operations and assist machinists in achieving greater productivity.

WatchFeatured Posts

5 Reasons Why You Should Know How to Write Custom Macros

Custom macros enhance what can be done in G-code programs, giving users the ability to code operations that were previously not possible.

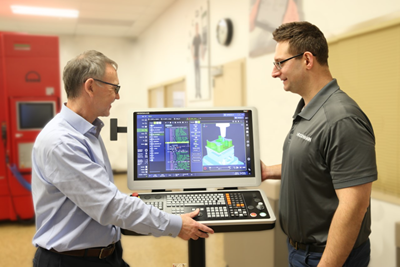

Read MoreGenerating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read MoreCan Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreWhen Handing Down the Family Machine Shop is as Complex as a Swiss-Turned Part

The transition into Swiss-type machining at Deking Screw Products required more than just a shift in production operations. It required a new mindset and a new way of running the family-owned business. Hardest of all, it required that one generation let go, and allow a new one to step in.

Read More7 CNC Parameters You Should Know

Parameters tell the CNC every little detail about the specific machine tool being used, and how all CNC features and functions are to be utilized.

Read More3 Examples of Machines that Combine Manufacturing Methods

Certain “hybrid” machines combine some form of additive manufacturing with CNC subtractive manufacturing. Columnist Mike Lynch, President of CNC Concepts Inc., explores three types of these machines here.

Read MoreFAQ: CNC & Machine Controls

What does CNC stand for?

Computer Numerical Control.

Source: CNC Intro-The Key Concepts Of Computer Numerical Control

What is CNC?

Computer numerical control (CNC) is the control of machining tools through automation or computer programming. A CNC machine follows coded instructions such as G-code and M-code. These instructions are typically written by a person or by CAD/CAM software. This allows for a highly automated process that can be more efficient than manual machining, providing users with better productivity, speed and accuracy. The most basic function of any CNC machine is automatic, precise, and consistent motion control. All forms of CNC equipment have two or more directions of motion, called axes. These axes can be precisely and automatically positioned along their lengths of travel. The two most common axis types are linear (driven along a straight path) and rotary (driven along a circular path).

How much does a CNC machinist make?

According to the Bureau of Labor Statistics (BLS), the mean annual wage of a CNC tool operator is $44,300 as of May 2020. The median wage is $42,260.

Further reading: New Apprenticeship Program At Hurco North America

5 Ways to Simplify Tasks for CNC Newcomers

Physics-Based Online Training in CNC Machining Available for Free Through DoD Initiative

What should new CNC machinists know?

1. Shop safety

First and foremost, newcomers to manufacturing must understand that the shop floor is a dangerous place. You must convey general concerns in two areas: safety equipment that workers use and safety practices to which they must adhere.

2. Shop math

The arithmetic that a typical CNC operator must be able to perform is simple. However, you must ensure that newcomers can use a calculator to add, subtract, multiply and divide.

3. Blueprint reading

Anyone working with CNC machines must be able to interpret a 3D workpiece from a series of 2D views on an engineering drawing. This involves understanding line types (visible, hidden, center, section, etc.) and orthographic projection.

4. Tolerance interpretation

Newcomers must understand that every workpiece attribute has an amount of allowable error, whether it be specified or implied.

5. Measuring devices

Explain the two basic types: fixed and variable gages. Go into detail for any fixed gages your CNC operators use, including go/no-go gages and gages that incorporate a dial indicator.

CNC & Machine Controls Supplier Categories

- CNC Software, Stand-alone

- Programmable Logic Controls (PLC)

- Communications Networks & Data Transmission Equipment

- Identification Systems

- Direct or Distributive Numerical Control (DNC) Systems

- CNC Units

- Digital Readout (DRO) Units

- Digitizing/Scanning Systems

- Memory Units

- Robot Controllers

- Machine Monitoring

- CAD/CAM Software

.png;maxWidth=300;quality=90)