Moving in with a Customer

Shop owner Chris Nachtmann has established a close relationship with one of his biggest customers. In fact, he moved his operation inside that customer’s facility a couple years ago. Now, he’s making greater strides to invest in and grow his business.

By 2010, Castle Metals had become a good customer for CNC Performance Engineering (CNCPE). So good, in fact, that the Charlotte, North Carolina metals supplier sent a couple trucks loaded with stock some 60 miles each day to Chris Nachtmann’s Lincolnton shop. Because Castle is a metals supplier and not a machine shop, it tapped CNCPE’s capabilities to perform value-adding, preliminary machining work requested by some of its big OEM customers. Those customers would then complete the final operations on the partially machined stock themselves.

When the time came a couple years ago for CNCPE to renew the lease at its Lincolnton location, Jim Marshall, Castle’s general manager, suggested that Mr. Nachtmann instead move his operation into Castle’s facility. CNCPE would benefit because there was more manufacturing activity in the Charlotte area than Lincolnton. In turn, Castle would benefit from quicker turnaround and more streamlined (and less costly) logistics for preliminary machining work.

CNCPE made the move to Castle in June 2010. Since then, both companies have experienced significant growth thanks to this atypical yet advantageous customer-vendor relationship. Now that CNCPE is settled in, the shop is focusing on implementing improvement efforts that will boost its competitiveness and enable further growth. I learned more about both companies during a recent visit with Mr. Nachtmann and Mr. Marshall at Castle’s Charlotte facility.

California to Carolina

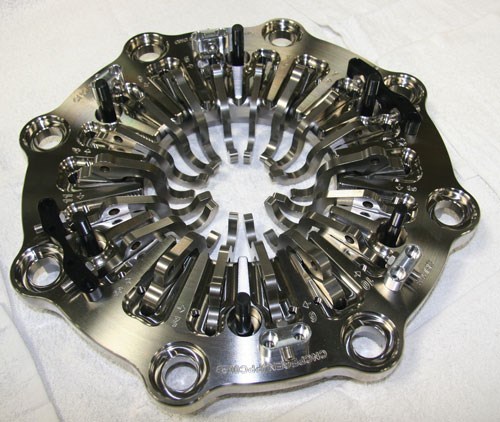

CNCPE’s winding road to Castle began in California. In 1971, Mr. Nachtmann’s parents, Larry and Mary Ann, founded Delta Fabricators in Los Angeles. Their shop became a prominent supplier to the aerospace and defense industries. Hoping to transition away from what oftentimes was stressful work serving those industries, the Nachtmanns established CNC Production Machine in 1987, shifting their focus to commercial equipment. For a time, Chris Nachtmann worked in the family business as a manual machine operator and welder. But in 1996, he left to pursue what would become a successful career as a crewmember for Top Fuel drag racing teams, specializing in clutch setups. (In fact, he developed a rugged titanium clutch design that he still manufactures and sells to various top fuel race teams.) He returned to the family business in 2002 when his father’s health began failing. Unfortunately, his father passed away a year later, leaving him and his mother to consider their next steps.

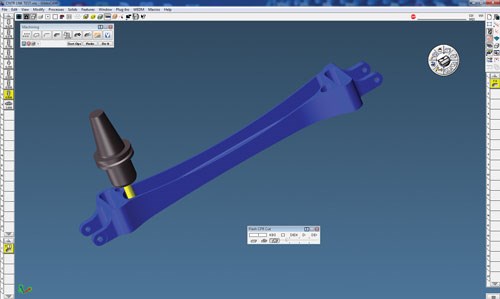

Mr. Nachtmann knew how hard his parents had worked over the years and how much their businesses meant to them. That spurred him to continue their legacy and assume a leadership role at the shop. However, he had no experience running a company and, just as significant, no knowledge of CAM programming (his father had done all the shop’s programming). He quickly realized that in order to quote new work, he first needed to identify a CAM package that not only offered the necessary part-programming features, but was also easy for him to pick up. After considering a few software companies, he settled on GibbsCAM in large part because it provided an intuitive interface, he says (see sidebar below). Mr. Nachtmann already had a firm understanding of what was involved in machining. Becoming knowledgeable with CAM was the missing piece that enabled him to get the shop’s machines up and running again.

But by the end of 2004, the shop had seen some good customers falter, and prospects for success in the Los Angeles area seemed dim. That’s when Mr. Nachtmann made another major decision: starting fresh in North Carolina. There, he could leverage the relationships he formed in drag racing and his knowledge of clutch design to provide machining services for a variety of performance racing applications while pursuing work in other industries.

Early the following year, Mr. Nachtmann transported a few CNC mills and turning centers across the country and established CNCPE in Lincolnton, which seemed like a good location near the South East’s performance racing community. By 2010, however, business was again down for CNCPE. That’s when Mr. Nachtmann decided to make one more move, this time across town to Castle.

On to Castle

CNCPE is a job shop that specializes in exotic materials such as titanium, magnesium, stainless steel and tool steel. The shop has customers in a range of markets, including agriculture, military, industrial equipment and performance racing. CNCPE began working with Castle in 2006 as part of the first-step machining process the metals supplier offered big customers that preferred to focus on detailed, final machining work rather than preliminary operations. By working closely with CNCPE, Castle could provide precisely the solution its customers desired while enabling them to streamline their supply chain and cut just one purchase order for the pre-machined stock they needed.

Having CNCPE on site provided even more benefits. Instead of trucking stock across town, Castle now delivers material via forklift to CNCPE’s area located near the facility’s loading dock. Mr. Marshall says this relationship has saved Castle tremendously in terms of delivery times and transportation costs while streamlining communication between the two companies. He estimates that Castle has won several millions of dollars in additional business thanks to the first-step machining service that CNCPE provides.

A chain divider defines CNCPE’s space inside Castle. Rather than waiting for Castle to cut blanks to size, CNCPE is set up as an inventory location in Castle’s database. The shop uses a conveyor that presents stock to a cutoff saw that creates blanks, which enables the shop to begin machining operations while the saw creates all the blanks needed for an order, rather than waiting for Castle to cut an entire batch of blanks to size.

The percentage of machining CNCPE performs with this first-step service varies according to the customer. Some customers require just basic turning or facing operations, while others might ask for as much as 75 percent of the machining work for a given component to be completed. Regardless of the amount of machining required, CNCPE still must deliver tight tolerances (sometimes down to ±0.0003 inch). A good example of this type of work is compressor shafts, in which Castle’s customer asks only for turning work so it can focus on machining only the rotors and flutes in-house.

Castle currently has six customers using the first-step machining solution. Mr. Marshall says he’d like to grow this number, but only at a manageable pace so as not to overload CNCPE. When one of Castle’s 20 salespersons has a customer interested in the service, he/she has Mr. Nachtmann participate in a meeting so he can answer any specific machining questions or review part prints to suggest what preliminary machining work makes most sense. The best applications are those with high-production volume, upwards of 100 pieces, which minimizes the inherent challenges of short-run work as well as those in which the material is large and represents a significant percentage of a component’s total cost.

From time to time, Mr. Nachtmann invites Castle sales personnel to the shop to teach them about the various machining processes the shop performs. Having a better sense about the type of work their customers are carrying out gives them a better chance of selling material, especially when pitching the first-step machining service. In turn, CNCPE has what effectively amounts to a bonus sales team helping to find new business.

Investing in the Future

Mr. Nachtmann admits that it has taken some time for the shop to bounce back from a few lackluster years. Now that business is better, however, he is focused on growing his seven-person operation and searching for equipment and technology that will boost competitiveness. For example, CNCPE recently assumed more space in Castle’s facility (expanding its footprint to 8,000 square feet) and added a Vektek LLCMazak Quick Turn Nexus 300 turning center to accommodate bigger workpieces. To ease loading of heavy parts, a gantry crane was installed at the machine. The turning center also has a tool setting probe for quickly establishing tool offsets. The shop will likely purchase another even bigger turning center at some point.

Not only is CNCPE adding capacity (it now has eight CNC machines), it is also making changes to boost shopfloor efficiency and effectiveness. Here are some recent examples.

• Faster fixturing on wire EDM—CNCPE is seeing a decline in sales for its titanium clutches for top-fuel dragsters. One reason is because there aren’t many independent Top Fuel drag racing teams these days. Instead, there are a handful of well-funded, multicar teams that have their own machine shops and can create their own components. Another reason is that the clutches are so robust and well designed that many are still in use today. However, there is still strong demand for its consumable clutch levers. CNCPE’s levers are machined from ground, heat-treated plate on a Robofil 310 wire EDM unit from GF AgieCharmilles. Wire EDM delivers the feature-to-feature accuracy of key lever points to ensure consistent, synchronized engagement with the clutch. Race teams have different specifications for their levers, and the wire EDM process enables CNCPE to machine any lever profile in short order. In addition, machining accuracy to the tenths means the teams can easily install the levers in their clutches without finish hand grinding to achieve final dimensions.

To speed setups for new jobs, Mr. Nachtmann created a fixture with locating pins to enable workpiece plates to be installed quickly and precisely. When the machine runs unattended (which is common), he sets up a wireless network camera in front of the CNC and uses a D-Link app on his smart phone to view the control while he’s away from the shop. That way, he can tell if a problem such as a wire break has occurred and come back to the shop to fix it.

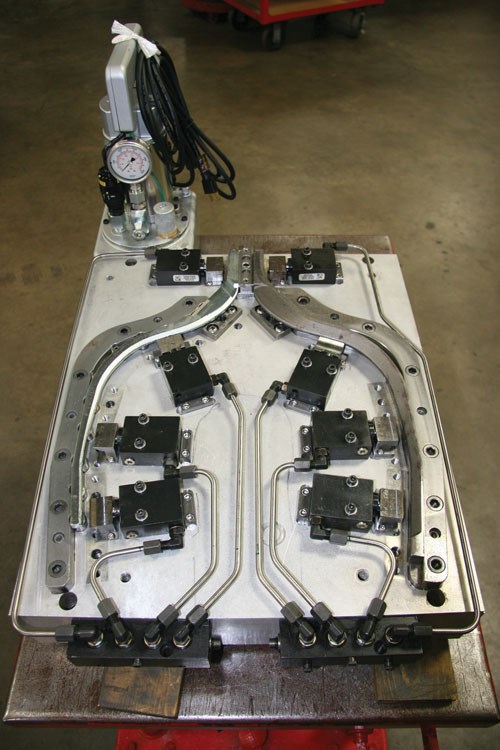

• Faster fixturing on VMCs—In 1990, Larry Nachtmann’s shop was chosen by A. L. Vandergriff, a man well-known in cotton ginning circles, to machine a new type of gin rib for cotton gin stands. This high-volume work continues today at CNCPE. The gin ribs are machined from 1018 steel forgings (see the photo below) that are first manually ground on one side in preparation for milling. The original fixture for the gin ribs was aluminum and used edge clamps along both sides of the parts. Operators had to take a great deal of care when installing parts using these clamps because the part could distort while being secured in the fixture. Depending on the operator, properly fixturing the parts could take longer than machining them.

In contrast, a new steel fixture that Chris Nachtmann developed has a solid profile stop for one side of the gin ribs and hydraulic clamps from Vektek to secure the other side. This improves fixturing rigidity to enable more aggressive cuts, greatly reduces refixturing time, and makes the process more consistent from operator to operator. As a result, gin rib jobs can be completed faster, freeing the VMC to perform other work. A second fixture is being constructed for use on the shop’s OKK VMC so that both mills can be used for very large gin rib orders.

• More effective job scheduling and tracking. As the business has grown, so has the challenge of monitoring the work that flows through the shop. As a result, Mr. Nachtmann recently begun using Exact JobBoss shop management software. He had been sitting on a license for a while, but simply never had the time to set up and implement the software. Mr. Nachtmann is currently configuring the system to track the shop’s most frequently repeating work, such as the gin ribs. A shopfloor computer station is provided so employees can scan the bar code on their badges and the job traveler for time tracking purposes. The JobBoss software enables Mr. Nachtmann to track as little or as much detail for a given job as he likes. Eventually, the system will provide access to setup sheets and part prints, and enable operators to add notes to document solutions they’ve developed for reoccurring problems with a job.

In addition to streamlining scheduling, the system is also enabling the shop to more accurately capture the true costs of jobs rather than going by gut feeling. For example, after entering all information for two jobs with seemingly slim profit margins, Mr. Nachtmann found that those jobs were actually his two biggest money makers. Similarly, a few other jobs that seemed highly lucrative were found to be unprofitable when lot sizes were below a certain amount.

• Better tracking of tool usage. Similarly, Mr. Nachtmann says a new vending system from MSC Industrial Supply has proven helpful in maintaining an appropriate inventory of cutters and inserts. For each job, employees scan their badge, enter a job number and remove the tooling they need. The vending system sends a weekly email that lists tools that need to be reordered. This has eliminated the all-too-common overnight orders for tools that the shop didn’t realize it had consumed.

• Improved machining with improved tooling. The shop is looking to new cutting tool technology to increase speeds and feeds for its machining operations. One example is the Power-Quad 45-degree indexable end mill from Ingersoll that replaced 90-degree versions previously used for the gin ribs. The Power-Quad’s positive rake face geometry yields less cutting pressure and requires lower horsepower, enabling feed rates for this application to be increased from 50 to 150 ipm (cutter diameter is 1 inch). Unequal insert spacing helps minimize vibration, too.

• Higher machine up-time via automated chip removal—The shop’s DMV 5020 (one of its two Doosan VMCs) commonly runs a job that requires significant material removal—specifically, machining 6-inch-diameter holes through 1018-steel workpieces measuring 6 inches tall and 11 inches in diameter. Because this VMC wasn’t originally fitted with a chip conveyor, operators had to stop after every fourth part to shovel chips out of the machine. To eliminate this wasteful step, CNCPE added a Turbo HB chip conveyor from LNS America that Mr. Nachtmann says will quickly pay for itself through vastly improved machine up-time. In addition, it frees operators to perform more valuable duties such as part measurement.

Keeping After It

Mr. Nachtmann’s goal in implementing these and other improvements (as well as cultivating the talents of his machine operators) is to enable the shop to run without him so he can spend more time drumming up new business. By July of this year, CNCPE had already surpassed its previous best sales year. However, Mr. Nachtmann realizes it’s important to be proactive in looking for new work even when business is good instead of waiting until activity slows before pounding the pavement. Plus, bringing in work from new and different industries leads to greater business stability when demand in any one market segment diminishes.

Related Content

When Handing Down the Family Machine Shop is as Complex as a Swiss-Turned Part

The transition into Swiss-type machining at Deking Screw Products required more than just a shift in production operations. It required a new mindset and a new way of running the family-owned business. Hardest of all, it required that one generation let go, and allow a new one to step in.

Read MoreERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read MoreShop Quotes Smarter, Works Harder with Machine Monitoring

Temco first installed MT-LINKi to optimize quoting. Now, the software helps the shop optimize its machines — and machine purchases.

Read MoreCan Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read MoreObscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)