Where Dry Milling Makes Sense

Liquid coolant offers advantages unrelated to temperature. Forced air is the fluid of choice in this shop...but even so, conventional coolant can't be eliminated entirely.

If metalworking coolant could always keep the cutting tool consistently and uniformly cool, then there would be no need for this article.

The problem is, liquid coolant has a way of cooling intermittently, and that fact creates a good reason to apply it with care. If the results of using coolant are dramatic and rapid temperature changes within the cut, then the coolant may do more harm than good. Many of today's cutting tools can stand up to high temperature so long as it's consistent, but they have little patience for change.

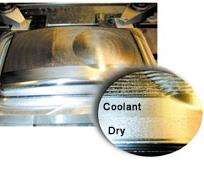

Stainless steel can be gummy enough that coolant may be needed as a lubricant when a ball-nose or other round-profile tool is used. That was the case with this Stavax 420 stainless steel mold core. When dry milling wasn’t producing an acceptable surface finish, the operator switched to using liquid coolant and the finish improved. Two finish-machined bands in the forward area of the part show the difference. The lower band in the inset photo is the area machined dry.

Alpha Mold (Dayton, Ohio) uses high-temperature cutting tools like these all the time. Back when the shop would mill out cores and cavities by burying a slow and heavy tool deep in the steel, flooding the job with coolant made a lot of sense. But Alpha doesn't cut that way anymore. Instead, the shop takes light cuts at high feed rates using 10,000-rpm machining centers. In place of a larger tool, the cutter of choice on these machines is often a single-insert milling tool from Millstar (Bloomfield, Connecticut), with the one insert made of carbide coated with titanium aluminum nitride (TiAlN). Cutters like this one have allowed the shop to reduce tooling costs significantly . . . but one key to realizing the savings is to run dry as much as possible.

How does TiAlN-coated carbide reduce tooling costs? Shop mold coordinator Bob Hansen explains. The old way to rough out a typical injection mold core or cavity would involve a five-insert slab mill, he says. Each insert would be indexed halfway through the job, so both cutting edges of the insert were worn out by the time the cut was finished.

At Alpha Mold, these nozzles are directing forced air onto the cut. The dry milling tool is coated in TiAlN.

By contrast, Alpha's high speed milling process allows just one of the coated carbide inserts to do the same job. Even though this insert is more expensive than one of the slab mill inserts, it's not five times as expensive. By using the one insert instead of five, the shop spends only about one-third of what it formerly would have spent on tooling for this cut.

To realize such long life from tools like this, the shop doesn't run liquid coolant while it cuts, but instead it replaces the coolant with 120-psi forced air. Alpha's machining centers deliver this air in much the same way they deliver coolant—by conduits that run through the spindle housing. However, a bolt-on air nozzle could accomplish much the same thing.

This forced air keeps the cut consistent in two ways. First, it's less effective than the liquid at cooling the tool. This is important for the TiAlN-coated tool, which performs better in consistent high heat.

Second, the forced air is more effective than the liquid at blowing away the small chips created during high speed machining's light cuts. These chips are often harder than the workpiece surface itself. Getting them out of the way of the cutter is a paramount concern, because recutting chips causes the load on the tool to spike in a way that can reduce tool life dramatically.

In the past, many shops in Alpha Mold's industry and in other metalworking sectors would have used coolant on all of their jobs as a matter of habit.

By running a TiAlN-coated tool in the consistent high-temperature conditions this coating favors, Alpha Mold lets one insert machine away the same volume of material that used to wear out five inserts, back when a different process and a different style of cutter were used.

But today, if a shop is using a more sophisticated process to take advantage of higher speeds, then the choice of liquid coolant versus forced air becomes one more component of the process deserving careful consideration. Both choices have their strengths. There are a variety of factors to take into account. (See sidebar entitled "Liquid Coolant Or Air? Take Four Factors Into Account" at the bottom of this article.)

For Alpha Mold, however, the matter is cut and dried. Across the variety of mold machining jobs the shop takes on (including injection molds, blow molds and molds for glass work), the shop uses dry cutting almost exclusively. In fact, rather than listing all the merits the shop does see in forced air, it's more instructive to focus on the specific cases where the shop still insists on using liquid.

Cases for Coolant

Deep cavity machining is one case where the shop still prefers to use coolant, Mr. Hansen says. The strong flow of liquid flushes the chips out of confined spaces where the forced air might not be able to carry them out. By the same token, the shop always uses coolant in drilling (generally delivered through the flutes of the tool). In both of these cases, coolant isn't used for any cooling value; it's used for chip evacuation.

Another case where coolant is used involves lubrication. With the move toward faster milling feed rates, the shop also has moved toward more use of ball-nose tools and other round-profile end mills in order to bring the part closer to its final form in roughing and finishing both. However, one problem with a ball-nose tool is that its shape produces vanishingly small cutting speeds ("sfm" approaching 0) near the ball's tip.

This characteristic of ball-nose tools creates a danger whenever two conditions are met—(A) the cut is very light, and (B) the workpiece surface is nearly perpendicular to the axis of the tool. Under these conditions, the tip of the tool is not truly "milling" so much as being dragged across the workpiece surface. With softer steels—particularly pre-heat-treated stainless, Mr. Hansen says—this effect can visibly affect surface quality. However, the lubricating property of liquid coolant can minimize the impact of this effect, thereby protecting the part's surface quality. Accordingly, whenever the tool is a ball-nose, the finish requirement is critical, and much of the part's geometry consists of nearly flat surfaces, Alpha Mold will often use coolant.

Mr. Hansen notes that there can be an interesting tradeoff here. The shop has observed that while surface finish improves with coolant, the location of the cut may shift by 3 to 5 ten-thousandths of an inch. One possible cause, he says, is that the pressure of the thin film of coolant between the tool and the workpiece is sufficient to deflect the tool by a tiny amount. Whatever the cause, the gain in surface finish sometimes comes at the cost of a small loss in dimensional accuracy.

In cases where Alpha Mold does use coolant, one thing the shop does not do is apply it only on those features of the part that seem to call for coolant's use. If running with coolant makes sense for some portion of the part, the shop runs coolant all throughout the cut. To do otherwise—that is, to run both wet and dry—might result in shocking a hot tool with coolant, potentially accelerating tool failure. If for some reason a part does calls for dry machining in one region of the part followed by wet machining in another, the shop is careful to insert a delay into the process to let the tool cool down gradually before coolant is applied. In other words, just as the shop would avoid any sudden moves in the tool path, it also avoids sudden moves where temperature is concerned.

Cutting on Air

Essentially for all of the rest of its machining center work, Alpha Mold runs entirely dry, using forced air as the only metalworking fluid.

Milling without covering the job in coolant may represent a departure from the way many shops routinely expect to machine. Even so, in many applications, this will be a departure well worth making. In shops like this one where high speed machining techniques are applied to tool steel, avoiding liquid coolant extends the tool's life. There are also secondary benefits. Not only does dry machining provide the accuracy improvements the shop has observed, the dry machining process is also cleaner.

Then there are the other sources of savings dry machining can deliver. Where forced air can be used more, so liquid coolant can be used less, coolant purchase costs go down . . . and coolant disposal costs go down at the same time. In this way, reducing the use of coolant saves money coming and going.

Related Content

Best Practices: Machining Difficult Materials

Cutting hardened steel, titanium and other difficult materials requires picking the right tools, eliminating spindle runout and relying on best practices to achieve tight part tolerances.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreToolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

Read MoreThreading On A Lathe

The right choices in tooling and technique can optimize the thread turning process.

Read MoreRead Next

Obscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)