Marposs Corp.

3300 Cross Creek Pkwy.

Auburn Hills, MI 48326 US

248-370-0404

marposs.com

IS THIS YOUR COMPANY?

As Seen On Modern Machine Shop

Marposs Corp. Supplies the Following Products

Trade Names Offered by Marposs Corp.

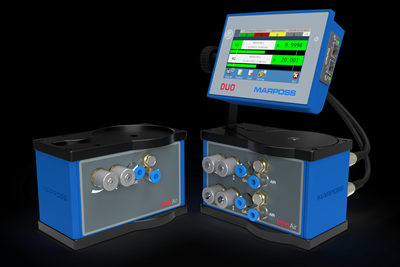

- Gage Box modular data acquisition system

- Merlin Mobile wrist-mounted Gauge Computer

- BLU one cable control network

- Quick SPC statistical process control software

- Mida Diamond

- M1Star MBG (Mechanical Bore Gauge)

- M2 Wave Wireless Electronic Snap Gauge

- M1 Wave wireless bore gauge

- EddyFlex NDT testing

- Mida Probes

- Laser 75P tool verification system

- iWave2 wireless handle

- DigiCrown digital measuring network

- Merlin gauge computer

- Nemo compact gauge computer

- E9066 industrial computer

- Easy Box, interface box

- Quick Set retoolable gauge system for shafts

- Red Crown pencil probe

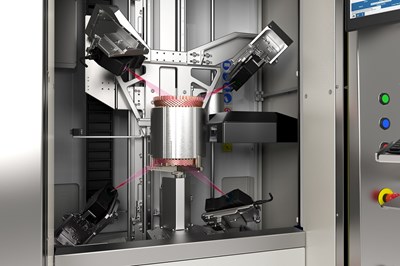

- Fenar grinder gauge head

- AMA, advanced measuring armset

- Quick Block universal measuring armset

- Mida ORI optical receiver

- Quick Read microcolumn measurement display

- Optoquick Set optoelectronic gauge

- Quick Snap retoolable manual snap gauge

- Mida OGP70 optical spindle probe

- Mida WRS (World Radio System)

- Unimar in process grinder gauge

- M3 Star Slim Snap Gauge

- Artis Brankamp machine monitoring

- M1 Star EBG (Electronic Bore Gauge)