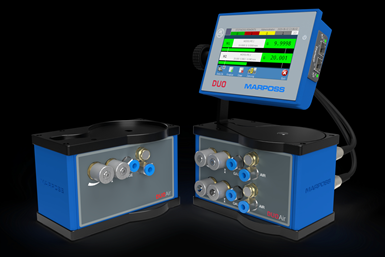

Marposs Introduces Air Gage Interface Box for Data Acquisition

The Duo Air can be supplied with one or two analog air-to-electronics converters with adjustable sensitivity and zeroing nozzles for connecting to one or two gauges.

Share

Marposs, a leader in measurement, inspection and test technologies, announces its new Duo Air interface box for easy and economical management of a wide range of air gauges. The Duo Air can be supplied with either one or two analog air-to-electronics converters with adjustable sensitivity and zeroing nozzles for connecting to one or two gauges. Each converter provides a linear variable differential transformer (LVDT) output signal for easy association to the Marposs’ Duo electronic display unit, offering a compact and affordable solution for measurement applications. Duo Air is said to be ideal for measurements with small tolerances requiring high resolution of 0.1 µm.

According to Marposs, the Duo Air is accurate, robust and versatile, with the ability to accept air gauges from other manufacturers. Both Marposs and non-Marposs air gauges can be easily and immediately connected to Duo Air, with consideration to the following parameters:

- Air supply pressure (3 bar ± 0.1)

- Number of air gauge jets

- Diameter of air gauge jets

- “Mid-range gap”; the difference between the mid-tolerance diameter of the part to be measured and the distance between the air gauge jets

In a typical application, the Duo Air reportedly offers linearity of < 0.4% of the working range, repeatability of < 0.15 µm, noise of <0.1µm, resolution of 0.01 µm and a response time of 200 milliseconds.

Related Content

-

How to Succeed as a Small Swiss Shop: Top Shops 2025

Can small shops succeed with advanced machine tools and software? If so, how do they do it? Read on to learn the strategies that have helped Midway Swiss Turn, our 2025 Top Shops Honoree in Shopfloor Practices, thrive.

-

Blueprints to Chips: CAD/CAM Tips and Tricks

This collection of articles delves into the latest CAD/CAM innovations, from AI-driven automation and optimized tool paths to the impact of digital twins and system requirements.

-

Legacy After Loss: Writing the Next Chapter of a Family-Owned Machine Shop

When a beloved machinist’s passing left his shop in his children’s hands, the three siblings stepped up, transforming the business to honor his legacy and build a new future.