Grinding

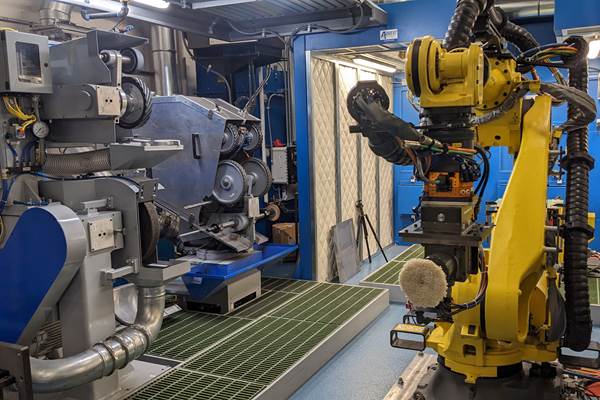

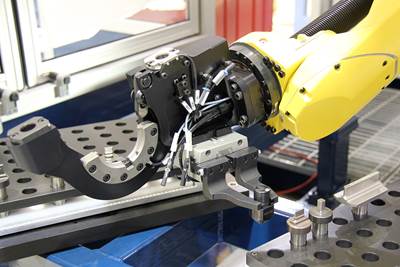

Grinding is a machining process that takes a very light “cut” using abrasive media—typically an abrasive grinding wheel. Grinding wheels with different grit sizes achieve rougher or finer grinding passes, according to the needs of the application. When precise accuracy and/or surface finish are required, grinding is often used as a finishing process after some other metalworking operation. Grinding is also an effective process for machining workpiece materials that are too hard for milling or turning. Grinders for round parts include cylindrical and centerless grinders. Grinders for flat surfaces are called surface grinders. Form grinders move the work and/or the wheel in various axes to grind surfaces that are precisely contoured. Grinders used to create and sharpen cutting tools are called tool & cutter grinders.

ESSENTIAL READING

VIEW ALL10 Things to Know About Creep-Feed Grinding

Because of the high material removal rate creep-feed grinding can deliver in challenging materials, grinding might not be just the last step in the process—it might be the process.

Read MoreChoosing The Right Grinding Wheel

Understanding grinding wheel fundamentals will help you choose the right wheel for the job.

Read More7 Key Factors in Choosing a Grinding Wheel

The grinding wheel market is wide, but seven application factors can help users narrow the market to the wheels they need.

Read MoreMachining 101: What is Grinding?

Grinding takes an abrasive — often attached to a wheel — and uses its many grains to cut a workpiece. Variations on this process are useful for a wide variety of applications.

Read MoreAn Introduction to Superfinishing

Learn what superfinishing is, what applications it should be used for and why you should take care when specifying surface finish parameters.

Read MoreChoosing the Best Abrasive Finishing Process for 3D Printed Parts

Studies have shown that abrasive finishing is flexible enough to finish 3D printed parts with complex geometries and difficult-to-machine materials, although the best process depends on a number of factors.

Read MoreLatest Grinding News And Updates

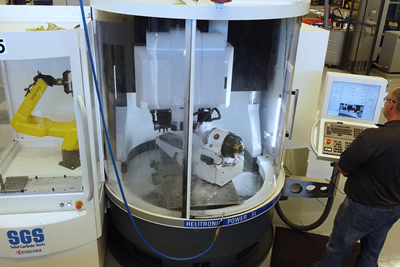

ANCA Grinding Solution Provides Flexible Five-Axis Machining

The TX7 Linear and TXcell Linear provide flexibility in the applications that can be put through it than other three-axis grinders more traditionally used for punch manufacturing.

Read MoreThe Keys to Combining High- and Low-Volume Production

Process expertise and precise production planning enable the Kinetic Company to produce both high- and low-volume jobs requiring machining, grinding, heat treatment and other processes.

Read MoreSteady Culture, Flexible Plans Enable Custom Tooling Success

By late 2019, West Ohio Tool’s client list only spanned one page. The company overhauled its culture and is now on track for its most successful year ever.

Read MoreSupertec Grinders Machine Small, Thin Parts

Available in both Plunge and Anglehead designs, Supra grinders offer a work envelope of 10" swing × 20", 30" or 40" between centers.

Read MoreJoint Ribbon Cutting at Fagor, Danobat Showrooms

Danobat and Fagor co-hosted an inaugural event for their co-located facilities in the Chicago area.

Read MoreChevalier Rotary Surface Grinders Provide Efficient Production

The FRG-400/600S Series is designed for heavy loads and is fully enclosed for CNC rotary surface grinding.

Read MoreFeatured Posts

Grinding Technology Prepares Manufacturers for Business Challenges

Studer’s automation solutions, S100 flexible grinding machine and intelligent coolant system can help users with unattended machining, machining a range of workpieces and saving energy.

Read MoreRebuilding Machine Centers: Low Cost, Higher Performance

By sending its grinding machines out for rebuilding, a tooling manufacturer achieved higher speeds at roughly three-fourths the cost of a new machine.

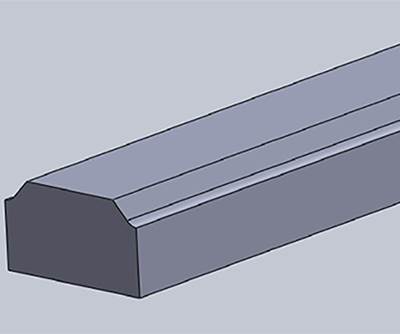

Read MoreReducing Prep Work With Precision Blanks

Precision blanks can reduce or eliminate prep work on machine centers, making spindle time more productive and improving throughput.

Read More10 Things to Know About Creep-Feed Grinding

Because of the high material removal rate creep-feed grinding can deliver in challenging materials, grinding might not be just the last step in the process—it might be the process.

Read MoreChoosing Optimal Superabrasive Grains and Coatings

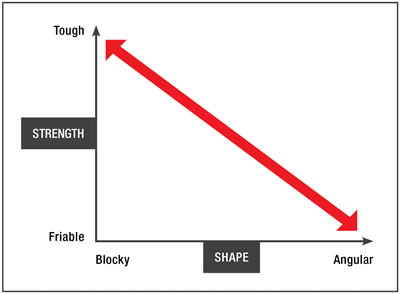

Superabrasive grain shape and coating composition play a large role in the suitability of grinding wheels for different applications.

Read MoreDigital Demo: People and History Drive Solutions

Bourn & Koch has long provided unique manufacturing solutions. However, the people who work at Bourn & Koch enable the company to deliver value to each partner they work with. From service to assembly to engineering, each step builds on the solution—helping you solve your most challenging manufacturing problems. (Sponsored)

WatchFAQ: Grinding

What is dressing?

Dressing is the process of sharpening the abrasive elements of the wheel. The process breaks down the bond and removes dull abrasive grains to expose new and sharp abrasive particles. Dressing also removes tiny pieces of material from the pores of the wheel face to prevent wheel loading, which can cause vibration and leave burn marks on the workpiece.

Without proper dressing, it's impossible to achieve the best consistency and adherence to specs from even the highest quality abrasive wheel. In fact, when you invest in top-quality grinding wheels, it becomes even more important to dress them properly in order to capture the quality and performance benefits.

Source: Dressed For Success

How do you dress a grinding wheel?

Dressing and truing grinding wheels prepare them for service and ensure proper accuracy for the grinding operation. Truing involves making the periphery of the wheel run concentric to the axis of rotation, and may require alerting the wheel by forming a special contour into its face. Dressing alters the cutting action of the wheel when the hard diamond point of a dressing tool breaks the bond posts of a vitrified wheel and fractures the grains, removing dull ones and making the new ones sharp. Dressing also picks up tiny pieces of material from the pores of the wheel face, ensuring that they do not slow the grinding process and cause burn or chatter.

Conventional dressing wheels do truing and dressing simultaneously with a light cut, while superabrasives require truing with a tool or roll, and separate dressing with a vitrified dressing stick. Before truing a superabrasive wheel, use a wax crayon over the wheel face — the process should eliminate all crayon marks by the end. Dressing a superabrasive will require direct application of a vitrified dressing stick (often aluminum oxide or silicon carbide, but sometimes high-performance norbide or boron carbide).

Source: Machining 101: What is Grinding?

What is grinding?

On its surface, grinding seems simple: a machine takes a rotating tool (usually a wheel) with abrasive grains and applies it to a workpiece’s surface to remove material. Each grain is its own miniature cutting tool, and as grains dull, they tear from the tool and make new, sharp grains prominent.

But there are many variations, approaches and considerations for this type of machining, each of which is particularly effective for certain applications with certain materials.

Source: Machining 101: What is Grinding?

What is creep-feed grinding?

Compared to the more common surface grinding, creep-feed grinding employs a heavier grinding depth combined with a slow traverse rate, generally with a profiled grinding wheel, to generate a given geometric form at a material removal rate (MRR) that is much higher than the finishing passes for which grinding is generally known.

What is Blanchard grinding?

Blanchard grinding is a brand name that has become generic in its use, much like saying Kleenex when referring to facial tissue. What began as a machine developed by the Blanchard Machine Co. in the 1900s is now a moniker generically applied to a number of rotary surface grinding machines including Blanchard, Mattison and others. In 2004, Bourn and Koch Inc. purchased OEM rights to Blanchard and Mattison, building new surface grinders in its facility in Rockford, Illinois, as well as offering retrofit and rebuild services for older equipment.

Rotary surface grinding works like this: A large workpiece is held on a rotary table with a magnetic chuck if the workpiece is ferrous or with custom fixturing if it is not. The machine’s table spins the workpiece under a vertical grinding spindle, and a segmented grinding wheel is lowered face-down into the workpiece, contacting the surface in much the same way as a floor polisher or a street sweeper. The grinding wheel spins counter to the table’s rotation, leaving Blanchard’s signature crosshatch pattern.

What is electrochemical grinding?

Although it has experienced a steady growth, electrochemical grinding (ECG) is mostly known as a niche process. Developed in the 1930s, it became popular in the US in the 1950s for grinding carbide cutting tools. At the time, the only other way to grind carbide was with an expensive, natural diamond grinding wheel. ECG has the ability to grind difficult-to-cut materials such as carbides, and this process became popular for producing cutting tools. But as disposable tooling inserts and molded near-net tool shapes were developed, ECG dropped off in popularity. Now, it’s mostly known in applications that work with challenging materials and thin-walled, fragile workpieces, including tubing cutoff, medical devices and parts for aircraft engines.

But according to Tom Travia, VP of Business Development at ECG equipment supplier Tridex (a Glebar company), potential applications for the process are again increasing as the technology advances. Today’s ECG provides an increasingly efficient option for machining challenging alloys, and OEMs in sectors such as medical see it as an effective way to machine precise components in these materials.

Grinding Supplier Categories

- Surface, Reciprocal Table

- Thread

- Wheels & Belts

- Grinding Wheels & Belts

- Disc, Single or Double

- Abrasive Belt

- Creep Feed

- Cylindrical OD

- Superabrasive Machining Systems

- Grinding Wheel Dressing Units

- Grinding Wheel Dressing Units

- Centerless

- Tool, Cutter & Drill Point

- Profile

- Jig

- Surface, Rotary Table

- Internal Cylindrical

- Attachments & Accessories

- Universal (ID/OD)

.png;maxWidth=300;quality=90)