October 2001 Issue

October 2001

Features

Featured articles from the October 2001 issue of Modern Machine Shop

Is It Time For Bar Fed Machining Centers?

When we think of bar feeders, usually they are associated with turning operations. Recently though, some builders have developed machining centers that incorporate bar fed raw stock. It’s an interesting idea for the right applications and one that can economically reduce material handling and fixturing requirements on machining centers. Here’s a look at how they work.

Read More

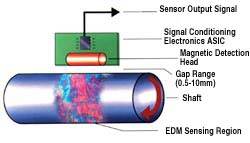

Magnetic Method For Measuring Torque

If you are monitoring changes in spindle torque as an indicator of tool wear or breakage, you will be interested in a new line of sensors that uses Embedded Magnetic Domain (EMD) technology-a combination of magnetic induction and electronic processing techniques-to provide low-cost, non-contact measurement of torque and angle on any nickel-bearing ferrous shaft.

Read More

Modeling The Future

During an era of reduced budgets, NASA launches a metalworking capability for the 21st century.

Read MoreVolume II, Issue X

Beyond MMS Online Whether or not you're aware of it, MMS and MMS Online have some "relatives"—both in print and online— that you should know about. Other properties launched by our parent company, Gardner Publications, offer very deep, informative sites that may deserve a bookmark or two in your browser.

Read More

Multi-spindle Thinking For Machining Center Parts

With 120 multi-spindle screw machines, this job shop naturally looked for technology that applied many of the key principles to non-rotational parts.

Read More

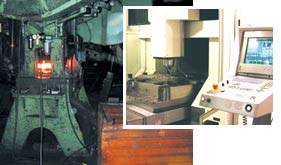

Pushbutton Die Making

High speed milling let this automotive forging company reverse a decades-old practice and bring die making back in house.

Read More

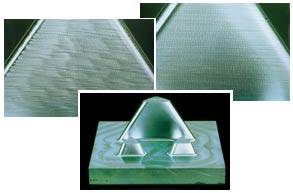

Curve Interpolation For Less

When the CNC executes the program faster, a higher feed rate becomes possible. Precisely this benefit has compelled many mold makers in particular to inquire about NURBS.

Read More

A Better Process For Bases And Plates

In a mold shop, the model of the customer's part gets used in two parallel processes. One of these is core and cavity machining, in which CAM software generates complex tool paths to let CNC machining cut the shape of the part in metal.

Read MoreLanding That First Customer

In recent columns, I have discussed starting a manufacturing business and have related some stories of companies that have successfully met the challenge. Even with all the efforts needed to get the business started, it does not take a company long to realize that to be successful, it must find and ultimately satisfy customers.

Read More