June 2014 Issue

June 2014

Features

Featured articles from the June 2014 issue of Modern Machine Shop

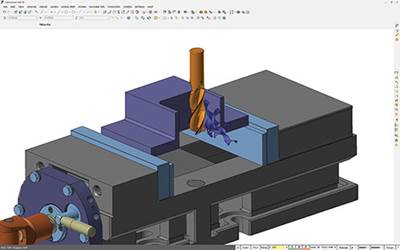

QFS Keeps Its Customers Moving With Integrated CAD/CAM

Quickly updating tool paths to remachine die surfaces enables this shop to provide short runs of prototype formed sheet metal parts. This fast response to engineering changes and design adjustments helps its customers adhere to tightly scheduled vehicle launch programs. QFS relies on integrated CAD and CAM software to make this happen. In this case, the software of choice are PowerShape and PowerMill from Delcam.

Read More

Aerospace Manufacturing Conference Returns to IMTS

TRAM 2014 will include two days of presentations on ideas and technologies affecting aircraft manufacturing. Here, speakers from Boeing and Airbus offer a preview.

Read More

Retired Yet Inspired to Learn Machining

A retired engineer with no prior machining experience is learning how to be a machinist. His quickly increasing skillset demonstrates how new machining technology is becoming more capable and easier to pick up and apply.

Read More

Dynamic Motion Moves Past Old Boundaries

The Dynamic Motion option in CNC Software’s Mastercam generates tool paths by following an expansive set of rules that are different from those most CAM software has traditionally followed. The motion of the tool is not defined strictly by boundaries of the area to be machined. Instead, the rules take into consideration not only the area from which metal is to be removed, but also the changing condition of the material throughout the various stages of machining.

Read More

Eliminating Tool Pullout in Titanium Milling

Toolholder employs a secondary locking system to counter the high axial cutting forces encountered during the development of a tool for high-metal-removal-rate milling of titanium.

Read More