March 2004 Issue

March 2004

Features

Featured articles from the March 2004 issue of Modern Machine Shop

A/B Rotary Head Turns Heads

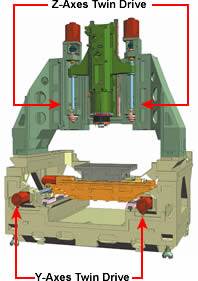

The A/B rotary head module on Cincinnati Lamb's new HyperMach rail-type plate mill might not be the first thing to catch the attention of aerospace shops. Perhaps it will be.

Read More

Single-Spindle Productivity

High speed, five-axis machining on single-spindle machine tools helps this aerospace shop meet the demand for rapid, single-piece work flow.

Read More

Consider Passive Damping To Bore Deep Holes

The old bromide, 'an ounce of prevention is worth a pound of cure,' comes into play for preventing chatter when boring deep holes.

Read MoreMore Than Just The Machining

Boeing representatives describe what they are looking for when they evaluate a machining supplier.

Read More

Taking No Chances With Quality

A shop's good reputation is hard to build and easy to loose. Consistent quality is key to keeping customers. In its 30-plus year history, this Chicago specialty grinding job shop has never taken quality for granted.

Read More

Minimizing Vibration Tendencies In Machining

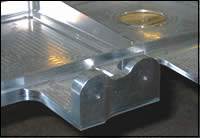

Precision internal machining operations are now carried out almost exclusively using hard-metal or diamond tipped cutting tools. Tool holders are available in a variety of forms to suit the specific machining requirements. The material properties of the toolholder have a large influence on both the surface quality and dimensional accuracy of the machined component (workpiece), and on the life of the cutting tool. This becomes critical when machining deep holes, because it is necessary to use a tool with large length to diameter (L/D) ratio or overhang.

Read More