June 2013 Issue

June 2013

Features

Featured articles from the June 2013 issue of Modern Machine Shop

Baklund: Lessons About Additive

Make extras. Make the part before even winning the job. Additive manufacturing encourages atypical strategies such as these.

Read More

Additive Manufacturing in the Job Shop

This small shop invested in production 3D printing in part because its owner expects other manufacturers to make the same move. He wanted a head start.

Read More

Probe Enables Finish Measurement on CMMs

The SFP1 probe uses technology incorporated in Renishaw’s five-axis Revo measuring head to facilitate surface finish measurement on CMMs.

Read More

How One Job Shop Tackled Tungsten

When this aerospace job shop settled on machining tungsten alloys and other heavy metals as its specialty, it had to have a machine tool, cutting tools, workholding and process know-how to succeed.

Read More

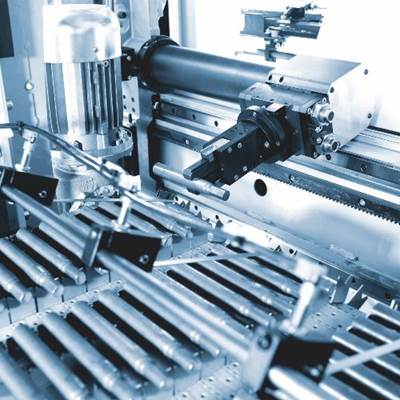

Space-Efficient Automation for CNC Lathes

Loader moves entirely within the footprint of the machine.

Read More

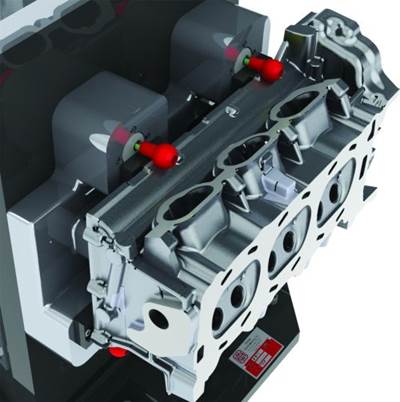

Retention Pins that Both Position and Clamp

Shops and fixture manufacturers commonly use spring-loaded retention pins in their workholding devices to ease part loading.

Read More