February 2005 Issue

February 2005

Features

Featured articles from the February 2005 issue of Modern Machine Shop

CAD Input For EDM

This software runs on the wire and ram (die sinking) versions of the company's "LQ" Windows XP-based control unit. The software provides a special interface that allows the user to input 3D solid model geometry directly from the CAD system to use as input to the EDM control unit. Using CAD data as direct machine tool input has long been a dream that developers of other types of machine tools are now closing in on.

Read More

Same Problem, Different Resolution

In shopfloor measurements, don’t count partial increments, but do keep a finer-resolution instrument handy.

Read More

Running EDM Economically

Many shops are taking a closer look at the cost of operating a machine tool. How much energy does it consume? Does it create excessive heat, making the shop air conditioning work harder? Does it stretch the life of cutting tools and consumables?

Read More

Optimize Cutting Efficiency, Optimize Throughput

A machining process based on maximizing cutting efficiency, rather than speeds and feeds, offers aerospace component manufacturers an option to high speed machining when high material removal rates are required. The best strategy may be to apply both machining concepts.

Read More

Adapting And Advancing

Assistive technologies for machinery and shop equipment allow blind workers at this machine shop to assume more advanced, independent roles in the production of aerospace components for Boeing.

Read More

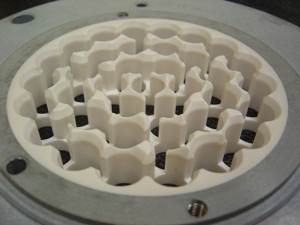

High Speed Wire Cutting Needs High Efficiency Filtration

High speed cutting with wire electrical discharge machining produces debris in the dielectric at a high rate. Without effective filtration, a wire machine quickly loses its ability to maintain high cutting speed, achieve the desired surface finish and obtain expected dimensional accuracy. Charmilles' approach to solving this problem has been to develop a filtration system that doubles the number of filter cartridges, from two to four.

Read More

Keeping Accuracy Within Reach

Part quality is at risk if a machining center cannot hold tolerances at the farthest reaches of its work envelope. This makes volumetric accuracy a key indicator of a machine's performance. One machine tool builder discusses the implications.

Read More

“Too Hard” Is Just Right

A user of ultrasonic machining looks for parts that are too hard to cut on other machine tools.

Read MoreManufacturing's Challenges And Opportunities

Makers of manufactured goods face many challenges, including increased competition in worldwide markets; a demand for more complex products; shortened delivery times; lower production costs; higher quality and longer life products; and increased pressure from consumers for variety and options in the goods being produced. The "one style/color fits all" mentality behind the mass assembly line is no longer an accepted approach for large-scale production.

Read More