September 2008 Issue

September 2008

Features

Featured articles from the September 2008 issue of Modern Machine Shop

.jpg;maxWidth=400;quality=70)

How To Machine Composites, Part 1 -- Understanding Composites

Composites are replacing metal in certain applications. What does this mean for machining?

Read More

The New Rules of Cutting Tools — Rule #2: Demand App Expertise

The support of a knowledgeable tool supplier should be part of what you purchase with the tool.

Read More

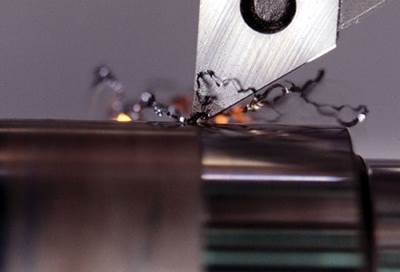

Turning The Tough Stuff

One of this aerospace shop’s many specialties is producing ring-shaped parts that are thin-walled, complex, tightly toleranced and made of difficult-to-machine materials such as Inconel, titanium or high-temperature alloys. Turning jet engine parts doesn’t get much tougher than this.

Read More

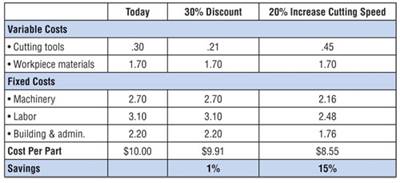

The New Rules of Cutting Tools — Rule #4: Focus on the Biggest Expense

Labor and machine time are where the real costs occur. The tool cost is tiny compared to the savings it delivers in these areas.

Read More

The New Rules of Cutting Tools — Rule #5: Consider the Cutting Tool at the Start

Are you specifying the right machine? You can’t know until you know what tools you will use.

Read More

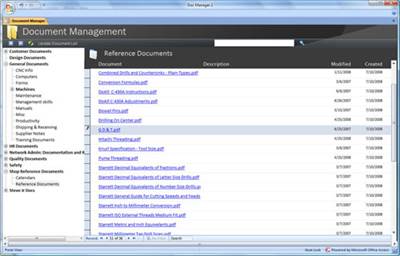

Managing Information Maximizes Efficiency

Using an intuitive, homegrown MRP system, this shop is able to effectively manage massive amounts of information while making necessary documents accessible anywhere they’re needed on the shop floor.

Read More.JPG;maxWidth=400;quality=70)

How To Machine Composites, Part 2: The Cutting Tool, Workholding and Machine Tool

In carbon fiber reinforced plastic (CFRP), the material removal mechanism is shattering instead of shearing. This makes it different from other machining applications.

Read More

The New Rules of Cutting Tools — Introduction

Cutting tool technology is evolving rapidly to respond to changing demands and more challenging workpiece materials. Shops today need to look at cutting tools differently. They need to look at cutting tool suppliers differently as well.

Read More.JPG;maxWidth=400;quality=70)

How To Machine Composites, Part 4 -- Drilling Composites

Achieving acceptable tool life and hole quality in a material such as CFRP demands a drill designed with composites in mind.

Read More

Automated From The Start

Turning automation helps this shop produce parts more efficiently.

Read More

Electrical Discharge Saw Slices Through Hard Alloys

Electrical discharge sawing uses spark-erosion technology and is said to create blanks from exotic alloys as much as 70 percent faster than wire EDM.

Read More.JPG;maxWidth=400;quality=70)

How To Machine Composites, Part 5 -- Waterjet Cutting

For trimming composite parts, this shop describes where it uses machining centers and where it uses waterjet.

Read More

The New Rules of Cutting Tools — Rule #3: Diamond Shouldn't Be Rare

Consider PCD or CBN wherever capacity is tight.

Read More.JPG;maxWidth=400;quality=70)

How To Machine Composites, Part 3 -- Milling Composites

Diamond shines for this shop when it mills composites.

Read More

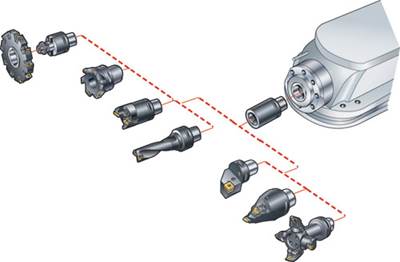

The New Rules of Cutting Tools — Rule #1: Do More With Your Machine

The tooling has the potential to transform the process.

Read More

Clean Fire Suppression Protects Machines, Workers

Machine tool fires can cause unscheduled downtime, or worse, damage to the machine itself and possibly a shop’s facility. In fact, Siemens Building Technologies (Buffalo Grove, Illinois) says that more than 10 percent of all machine tools using non-hydrous coolants will have a fire incident within five years after installation.

Read More