EDM

Exploring Niches With New EDM Technologies

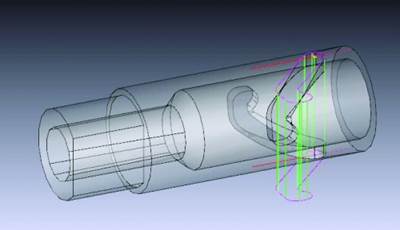

A shop specializing in wire EDM for large mold components now offers EDM “turning” of small, intricate parts. Despite the potential risks involved in early adoption of new technologies, the shop believes this practice gives it a leg-up on the competition and lets it gain experience with alternative machining techniques before offering them to customers.

Read MoreCheck Machine Details Before Delivery To Your Shop

When I am interested in writing about a new type of machine tool, I like to visit a shop or plant that has a representative model in place. Getting this user’s perspective is more objective and more relevant than just picking up info from other proponents. Writing the article is more fun, too. So typically, I talk

Read MoreElectrical Discharge Saw Slices Through Hard Alloys

Electrical discharge sawing uses spark-erosion technology and is said to create blanks from exotic alloys as much as 70 percent faster than wire EDM.

Read MoreGraphite Series Offers Strength

Toyo Tanso’s TTK-4 grade of graphite is the fine-grain offering of the TTK series product line of ISO statically molded graphite. It is suitable for the medical and aerospace fields. The key attributes of this grade are said to be strength, machineability and resultant-quality surface finish. The company’s other

Read MoreCompact Handling Facility Sticks To Basics

Shops consider a number of factors when justifying automated parts storage systems, including cost, required floor space and machining application.

Read More