Probing for Setup and Lights-Out Machining — The One-Person Shop Episode #2

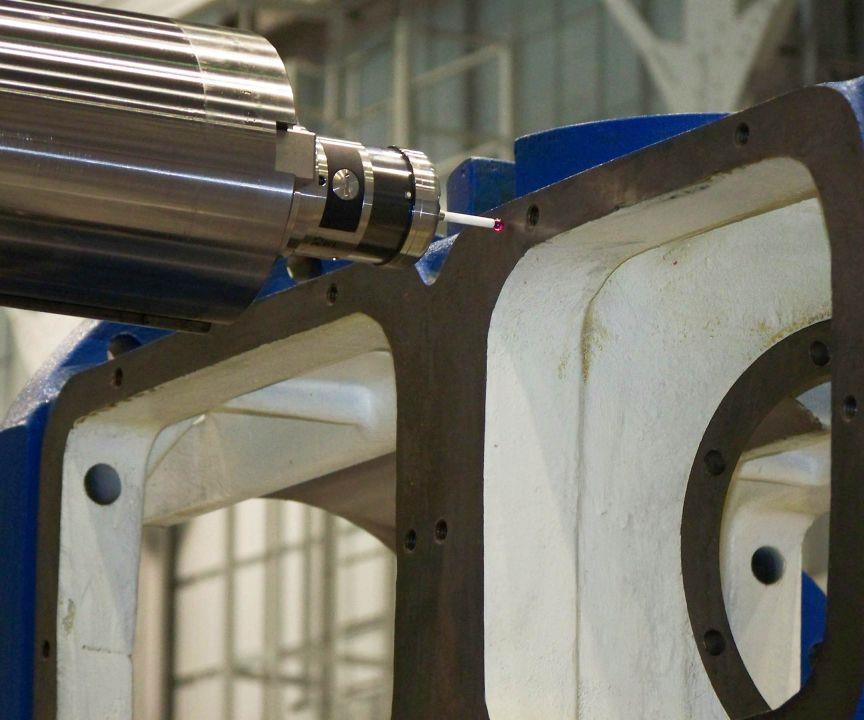

Automatic measurement on the machine tool speeds efficiency by day and safeguards capacity at night for a small machine shop.

One-person machine shop owner Dan Donaworth, owner of Dan’s Custom Machining, says he needs to run his machine tools lights-out “just so I can get some sleep.” The shop keeps making money after hours in this way, but a tool break or a mislocated part during this unattended machining could be disastrous — resulting in a scrapped part or a crash that damages the machine. On-machine probing, both to measure the part and to measure the cutting tool, is the safeguard that helps ensure effective unattended production by checking for these concerns.

Probing helps during the daytime, too. Setup time is the chief efficiency challenge for any small job shop. Relying on probing allows setups to be performed much more rapidly. Dan Donaworth talks about his use of machine tool probes (from Renishaw) in the latest episode of our video series, “The One-Person Shop”:

Transcript

Peter Zelinski

Pete Zelinski, Modern Machine Shop. This video series is The One-Person Shop. We are looking at ideas, technologies that allow a very small shop to be very competitive. We're at Dan's Custom Machining, Williamsburg, Ohio. Dan Donaworth is the sole proprietor, sole machinists, sole programmer. Dan, thanks for having us back.

Dan Donaworth

No problem. I'm glad that you guys can be here.

Peter Zelinski

So with this episode, we're going to talk about measurements that happen inside the machine tool, we're going to talk about probing, tool brake detection. On your machining center these were options, you didn't have to have these. How much did you pay to have that extra option, and was that something you had to think about?

Dan Donaworth

It was about $8,000, I believe for the package to be added on when I was ordering the machine. And for me, it was a no brainer. I've never even questioned buying a machine without probing in today's world. It's just not something I would ever think about doing.

Peter Zelinski

So that option is a bargain. And talk a little bit about your perspective, why that's such a bargain to have that capability on the machine.

Dan Donaworth

For me being a one man shop, I do a lot of running unattended. So I will load a machine up and let it run throughout the night, so I can hopefully get some sleep. So for the peace of mind of knowing that you're not going to wreck a tool into a part. I mean, even if you do break one tool, it's not going to keep smashing every tool beyond that into the part or even worse, take a big indexable cutter and wreck the head of your machine full rapid into what was not supposed to be there because a tool before was supposed to take it out.

Peter Zelinski

All right, you're talking about lights out machining and the value of that. I think we're going to talk a little bit more about that. But first, more general, bigger picture, what have you learned about probing or tool break detection in the time you've used it? How have you gotten better, or what have you discovered about how to use it effectively.

Dan Donaworth

Setting up of parts has become the biggest effectiveness of it as far as driving cost down. Being a job shop, you're doing setups all the time. You're even taking vices on and off the machine all the time. Whereas if you just need to throw a vise up to do some, and you're only holding a part in one vise, you can use scaling coordinate rotation to where you don't have to indicate that vise and you could just probe the solid jaw of the vise and tell the machine - it automatically tells it what angle its set at. You save yourself the time as we're a machinist before would have to run an indicator across the surface, get it just right, and then move on.

Peter Zelinski

So in the part that we're seeing as a demonstration, what is the feature that the probing is locating off of?

Dan Donaworth

The probe is going to be locating off of a bore of a part. And it's going to have two separate holes so it can align the part and the plane rotation.

Peter Zelinski

And so the entire coordinate axis of the program is going to rotate mathematically based on those two bore locations.

Dan Donaworth

Correct.

Peter Zelinski

Okay, so for for this same job, as the hypothetical, what if you didn't have probing capability? How would you set this up?

Dan Donaworth

I would approach it as putting dowel pins into the hole. And then you would have to trim your vise in to those dowel pins true to one another. So you would be manually trying to set it up and it wouldn't be near as accurate or efficient.

Peter Zelinski

Okay, so that was probing and you're using that significantly for setup. And then there's also tool break detection. And you're using that largely so that you can walk away from the machine and even leave it running all night. How common is it that tool break detection saves you, that it actually detects a problem with a cutting tool that's been loaded?

Dan Donaworth

Hopefully it doesn't save me that much because that means I'm breaking tools but it does happen and it is a lifesaver when it does. Really all it takes is detecting it one time could save you $1,000 if not more and machine downtime if it would be a major wreck that would happen after.

Peter Zelinski

Yeah, so it can be a lifesaver. Talk about that a little more. What is the potential risk of a tool break going undetected.

Dan Donaworth

The biggest potential risk would be a big high feed indexable cutter that was supposed to be coming down into an area that was already machined out by a previous tool and your machine is set at 100% rapid and it just smashes that cutter down into the part which then damages and puts pressure on your spindle and all your Z axis and everything else.

Peter Zelinski

So really, you have all this capacity in this shop, this machining capacity and it can produce for you while you're sleeping like you say. And it sounds to me fair to say, you couldn't use the capacity that way if you didn't have that tool break detection as safety.

Dan Donaworth

No, no, I couldn't operate without the tool break detection with peace of mind or the chance of ruining everything.

Peter Zelinski

That measurement detects an error in the cutting tool somehow. What happens then typically? Does just the whole process come to a stop, or is there a plan B programmed in?

Dan Donaworth

It really depends on how you go about programming. If you don't have enough tool spaces in your tool magazine for a spare tool, then the program will just alarm out. If you have room you can program a - Say you have a small tool that is prone for breaking. You could program it to where if that tool broke, it would call up the next tool in line that you program.

Peter Zelinski

Is that option typical for you, that if-then option programmed in?

Dan Donaworth

It is on certain jobs. A lot of the jobs we run we use most of our tool capacity, so we don't have much room for spare tools for that. So it is something that we have used, but we really need more tool capacity.

Peter Zelinski

All right, The One Person Shop. Keep watching these videos. How to deal with all the cutting tools, we're actually going to do an episode on that too. Stay tuned.

Related Content

Twin Spindle Design Doubles Production of Small Parts

After experiencing process stalls in the finishing stage of production, Bryan Machine Service designed an air-powered twin spindle and indexable rotating base to effectively double its production of small parts.

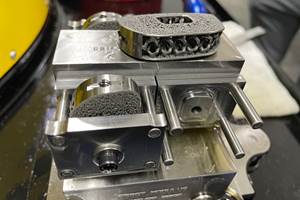

Read MoreAn Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

Read MoreHow to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read MoreFearless Five-Axis Programming Fosters Shop Growth

Reinvestment in automation has spurred KCS Advanced Machining Service’s growth from prototyping to low-and mid-volume parts. The key to its success? A young staff of talented programmers.

Read MoreRead Next

Vacuum Workholding for Thin Parts: First Episode of The One-Person Shop

A new video series looks at technology and practices for thriving as a very small machining business. In this episode, how workholding using air pressure permits rapid setup of parts too delicate to be held in a vise.

Read MoreSeven Tips to Ensure Accurate Probing

When used correctly, probing can have significant cost, efficiency and quality benefits.

Read More5 Hard Lessons from a 28-Year-Old Startup Machine Shop Owner

Good fortune and years of long working hours have both figured into the success of this young shop, which became its founder’s sole employment starting last year. The shop owner shares his story.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)