Vacuum Workholding for Thin Parts: First Episode of The One-Person Shop

A new video series looks at technology and practices for thriving as a very small machining business. In this episode, how workholding using air pressure permits rapid setup of parts too delicate to be held in a vise.

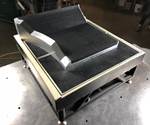

In a small job shop doing short-run work, where fast setup and a trouble-free machining process determine the job’s profitability, what is the effective way to hold thin, delicate aluminum parts? The answer Dan’s Custom Machining found is vacuum workholding. This video describes the use of quick-setup workholding using the force of vacuum pressure (supplied by Pierson Workholding).

This video is the first episode of a new series from Modern Machine Shop, “The One-Person Shop.” Various technologies in tandem, new and old, enable a very small shop to function effectively, including the smallest possible shop: one employee. Episodes in this series will look at different technologies and practices valuable to the productivity and profitability of a one-person machining business.

Related Content

-

A Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

-

IMTS Takeaways From the Modern Machine Shop Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

-

Using Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)