Aerospace Machining

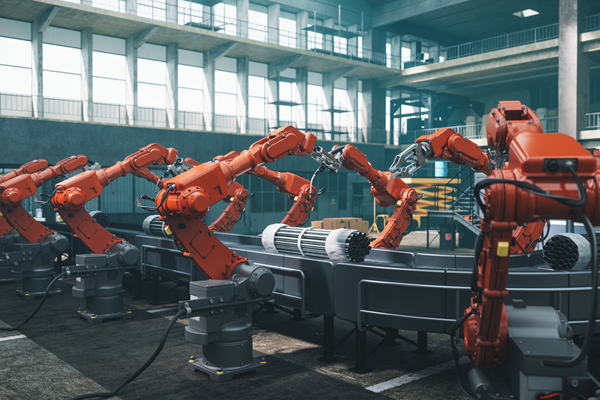

Aerospace machining is frequently characterized by the tight tolerances and hard-to-machine metals typical of aircraft engine components, as well as the complex contours typical of both turbine blade forms and the aerostructural components making up a plane’s form. Because machined contours are so typical, five-axis machining is routine in this sector, include large-travel five-axis machine tools able to accommodate the largest aircraft structural components. Materials typical of aerospace machining include lightweight aluminum for structural members; hard and temperature-resistant metals including titanium and Inconel alloys for engine parts; and carbon-fiber composites that are both hard and lightweight for outer skins. Along with large five-axis machines, turn-mill machines and precision grinders are among the high-value machine tools routinely used in this sector.

Latest Aerospace Articles

VIEW ALLBavius Technologie Appoints New President, Schedules Technology Showcase

Roy D. Cripps will lead the team at Bavius as it aims to expand its current business in aerospace structures and develop new market segments. Additionally, the company will showcase its technology during an open house event on June 11.

Read MoreRego-Fix Appoints New Global Aerospace Specialist

Sherman D’Souza will provide global customers with access to Rego-Fix research, development and technical support teams to create and supply toolholding solutions.

Read MoreHorizontal High-Speed Machining Saves Hundreds of Work Hours

High-speed machining is the latest change at Blair-HSM South, helping this once old-fashioned shop improve productivity and morale while enabling new work.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreGrob Systems Inc. to Host Tech Event With Industry Partners

The 5-Axis Live technology event will highlight new machining strategies for optimizing the production of complex medical, aerospace and mold/die parts.

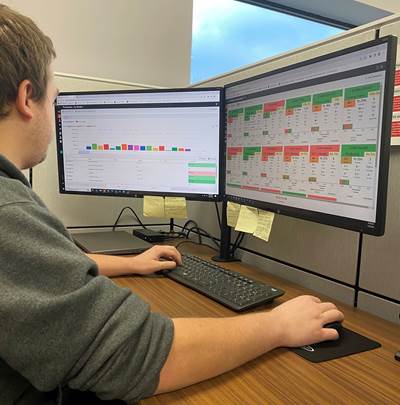

Read MoreMachine Monitoring Boosts Aerospace Manufacturer's Utilization

Once it had a bird’s eye view of various data points across its shops, this aerospace manufacturer raised its utilization by 27% in nine months.

Read MoreLatest Aerospace News And Updates

Solar Atmospheres Receives Northrop Grumman Approval for South Carolina Facility

All five Solar Atmospheres facilities are now an option for customers with Northrop Grumman requirements for vacuum heat treating.

Read MoreSolar Atmosphere Receives Boeing Approval for Vacuum Oil Quenching

The approval was granted for oil quenching of alloy steels in the company’s new furnace, the Neo.

Read MoreArch Cutting Tools Acquires Custom Carbide Cutter Inc.

The acquisition adds Custom Carbide Cutter’s experience with specialty carbide micro tools and high-performance burrs to Arch Cutting Tool’s portfolio.

Read More10 Things to Know About Creep-Feed Grinding

Because of the high material removal rate creep-feed grinding can deliver in challenging materials, grinding might not be just the last step in the process—it might be the process.

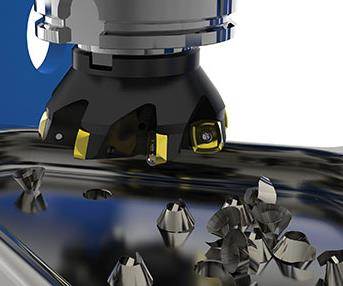

Read MoreSandvik Coromant Extends Line of Ceramic Milling Heads

Sandvik Coromant has developed two solutions designed for shoulder and face milling of nickel-alloy aero-engine parts.

Read MoreWhen a Lathe With Live Tooling Rivals a Multitasking Machine

This shop is working its way up to a full-fledged B-axis multitasking machine. Meanwhile, turning centers with a Y-axis and live tooling are doing just fine.

Read MoreFeatured Posts

10 Tips for Titanium

Simple process considerations can increase your productivity in milling titanium alloys.

Read MoreOut of This World: Space Exploration Innovations at IMTS

The more time passes, the more it becomes clear that space exploration and manufacturing have a close-knit future together. (Click through for a slideshow of the coolest space gear we found on the show floor!)

Read MoreIMTS is the Place for Aerospace

The aerospace industry will receive a lot of attention at IMTS, as conferences explore both the material and process needs of the complex, advanced industry. (Check out the slideshow for aerospace industry highlights!)

Read MoreHow to Turn Machine Shop Downtime Into Process Expertise

To take advantage of a lull in business, JR Machine devised a week-long cutting tool event that elevated the shop’s capabilities with aerospace alloys.

Read MoreWhen Organic Growth in Your Machine Shop Isn’t Enough

Princeton Tool wanted to expand its portfolio, increase its West Coast presence, and become a stronger overall supplier. To accomplish all three goals at once, acquiring another machine shop became its best option.

Read MoreThe Strategic Value of Machine Tool Flexibility

This aerospace and defense supplier has a strategy to take advantage of the flexibility in its newest and largest five-axis gantry-type machining center.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)