Automotive Parts Manufacturing

Numerous advanced machining technologies are being leveraged to enable automotive parts to be manufactured more effectively, be they by high-production OEMs and Tier-One suppliers, aftermarket product companies, race team and engine builders, and so on. Examples include honing, grinding, gear manufacturing, five-axis machining, robotic and transfer line automation, reverse engineering, and prototyping (which might involve traditional subtractive machining or additive manufacturing/3D printing). Data-driven manufacturing strategies are also increasingly being adopted as shops look to establish more effective measures for tight process control and high quality.

Latest Automotive Articles

VIEW ALLMarposs Celebrates its Past, Eyes Future Opportunities

During its open house in Auburn Hills, Michigan, Marposs presentations focused on future opportunities across growing industries such as EV and semiconductors.

WatchEliminating Automotive Defects Per Million With Automated Visual Inspection

This automotive manufacturer virtually eliminated PPM defect complaints after implementing an automated visual inspection system at its facility.

Read MoreDN Solutions Responds to Labor Shortages, Reshoring, the Automotive Industry and More

At its first in-person DIMF since 2019, DN Solutions showcased a range of new technologies, from automation to machine tools to software. President WJ Kim explains how these products are responses to changes within the company and the manufacturing industry as a whole.

Read MoreSunnen Products Company Partners With Hendrick Motorsports

The partnership puts the new Sunnen SV-series honing machine in the Hendrick Motorsports engine operation alongside other Sunnen honing and engine building machines.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreArch Cutting Tools Acquires Custom Carbide Cutter Inc.

The acquisition adds Custom Carbide Cutter’s experience with specialty carbide micro tools and high-performance burrs to Arch Cutting Tool’s portfolio.

Read MoreLatest Automotive News And Updates

Ford Partners With Rockwell Automation to Advance EV Program

The companies will jointly collaborate on assembly tooling designs and architectures that will increase speed to market.

Read MoreNew Laser Technology in Non-contact Optical Dimensional Metrology

LADAR technology from API sets a new standard in non-contact optical dimensional metrology for manufacturing industries.

Read MoreElectric Vehicles Spark Bright Ideas

Ford alone expects to have production capacity for 600,000 electric vehicles by late 2023, and more than 2 million by the end of 2026. The effects on manufacturing are BIG.

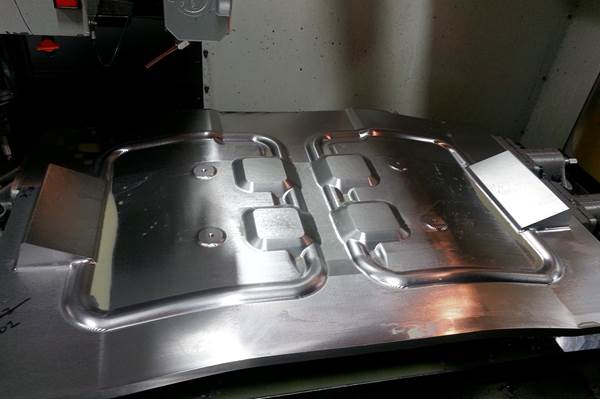

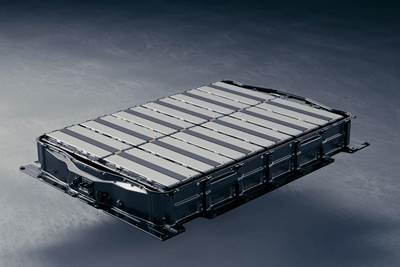

Read MoreHow is an EV Battery Made?

Everyone talks about batteries, but how are they produced? Here’s the long and short (circuit) of it.

Read MoreSiemens and Mahle Partner to Develop Wireless EV Charging

Mahle will contribute its experience as an automotive supplier and Siemens will use its expertise in the field of charging infrastructure to develop wireless charging stations for electric vehicles.

Read MoreSandvik Coromant on Acquisitions: Solutions Entail More Than the Tool

A Q&A with global president Helen Blomqvist explores the cutting tool maker’s acquisition of CAM software companies and how this connects to, among other things, electric vehicles.

Read MoreFeatured Posts

How This Motorcycle Startup Will Succeed With U.S. Production

Land Moto is the founder’s second motorcycle company. The first time, production was in China. This time, several factors help advance the effort to produce a low-cost bike in the United States. One of these is the way electrification opens doors to suppliers.

Read MoreGenerative Design for Milling Lightweights EV Motorbike Part

Autodesk’s Fusion 360 generative design function can create mass-saving solutions for three-axis milling and other conventional manufacturing processes.

Read MoreIncrease Profitability 17% with Exporting

This short tutorial will empower you to find the right market for your product, ensure you get paid, and provide resources to get started. (Sponsored)

WatchEnd Mill and Collet Combo Cuts High-Speed Machining Costs 62%

Switching to Emuge-Franken helped precision production machine shop SB Dezigns save 62% in costs on a popular automotive part while lowering cycle times.

Read MoreReal Examples of 3D Printing in the Automotive Industry

3D printed end-use parts are going onto vehicles with increasing frequency. Recent real-world examples showcase additive manufacturing benefits in design, weight savings and more.

Read MoreNidec Acquiring Mitsubishi Heavy Industries Machine Tool

Motor manufacturer looking for ways to more efficiently manufacture so it is buying a machine tool company

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)