Robots and Automation in Metalworking

Machine-tending robots are often key components used to enable unattended or lights-out machining operations, adding capacity by taking advantage of time that’s currently unused, like nights and weekends. In many cases, robot integration enables shopfloor employees that were previously loading and unloading parts from machines to perform duties of greater value. Plus, today’s robots are faster and more intelligent than in years past and are also becoming increasingly viable for small-batch/high-mix production. In addition, collaborative robots, or “cobots,” use sensor technology that enables them function safely alongside humans in a shared work environment. That means no more isolating fencing is needed to separate worker and robot.

ESSENTIAL READING

VIEW ALL4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreMade in the USA - Season 1 Episode 2: The Automation Puzzle

There is a fundamental question we need to answer when we talk about automation: To what extent is automation an answer to the skilled workforce shortage, and to what extent is automation vs. Skilled labor the wrong comparison to make in the first place?

ListenChoosing a Five-Axis Machine Tool With Automation in Mind

While much focus is placed on the machinery that moves parts, the features most important for automating five-axis machining are arguably found in the machine tool itself.

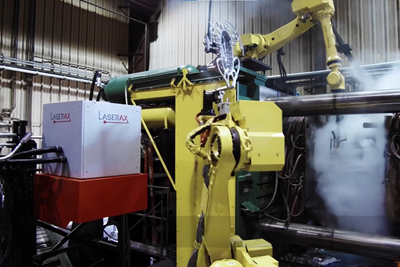

Read More5 Tips for Automating Laser Marking With Robots

Automating laser marking can be a useful way to increase robots’ utilization, but the process requires careful planning for success.

Read MoreReducing Machine Cycle Times Both In and Out of the Cut

Increasing automation means setup times are lower than ever. How can shops optimize cycle times to match and win more business?

Read MoreTurn-Mills 101

Turn-mills are a type of multitasking machine that can shorten cycle times and help facilitate lights-out machining for two common machining types.

Read MoreLatest Automation News And Updates

Omron Automated Mobile Robots Provide Reliable Transport

The MD-650 and MD-900 AMRs are designed to safely pick up, transport and drop off pallets and cargo.

Read MoreStuder's Automation, Entry-Level Solutions Take Center Stage

At its 2024 Music Motion Meeting, Studer AG showed off its entry-level line of grinding machines, as well as its newest universal loading system.

Read More3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

Read MoreKuka AR Software Enhances Robotics Error Detection

Kuka.MixedReality software displays tools and interference geometries for early detection of potential hazards that can then be eliminated before a robot starts to work.

Read MoreMurata Machinery USA Celebrates 50 Years

Muratec’s technology has marked turning points in automation, helping customers enhance competitive efficiencies across diverse industries.

Read MoreEdge Technologies Bar Feeder Automates Short Production Runs

The Rebel 80 Servo v3 is a specialized solution for automating short production runs at an economical price.

Read MoreFeatured Posts

How to Choose the Right Automation Solution for Your Shop

Consider what types of implementation your shop prefers when deciding between workpiece-handling and pallet-handling automation solutions.

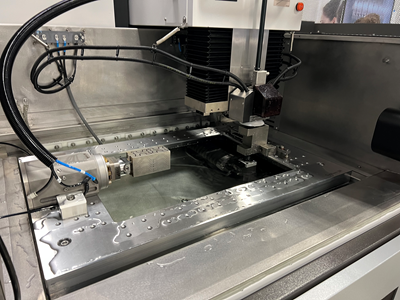

Read MoreHybrid Control Makes Lights-Out EDM More Accessible

This CNC enables EDMs to switch between G-code and an integrated CAM system to adapt to changing conditions and make lights-out manufacturing more attainable.

Read MoreMedical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

Read MoreHermle Event Encourages, Educates on Five-Axis Machining

Hermle’s first Five-Axis Summit was designed to show beginners the benefits of five-axis machining and demonstrated how more advanced users can take their capabilities to the next level with automation.

Read MoreQ&A: How a Self-Taught Machinist Started His Own Business

This machinist found an opportunity in a niche market and decided to learn machining and create his own business. Here's how he did it.

Read More3 Lessons Job Shops Can Learn From Laser Cutters

This laser-cutting “job shop” designs its processes to make high-mix, low volume work profitable.

Read MoreFAQ: Automation

What is automation?

“Robot” is the first picture that comes to mind, but it means more than that. Automation could be machines that are able to do more in one setup, one handling. It also refers to other options like pallet systems for moving work around, in and out of machines. It refers to software that can automate certain operations. Automation is not a replacement or an alternative for people.

What is a cobot?

A collaborative robot or “cobot” is a robot that is safe to run unguarded near people. Most cobots are safe because they are speed- and force-limited, and they stop upon sensing contact with an obstacle. Cobots are also easy to relocate and reprogram for different tasks in a shop.

What should you know about cobots?

1. Cobots, vision and AI all go together.

2. Cobots do not guarantee safety.

3. Cobot applications need not feature collaboration.

4. Automation’s payback period is declining.

5. Trends in manufacturing favor collaboration.

6. Cobot adoption might be held back by lack of people.

7. Advancing AGV technologies make cobots mobile.

8. Attention recognition is coming.

9. Collaborative can be done in different ways.

10. “Collaborative” can be a bigger idea.

How do robots and 3D printing intersect?

1. 3D Printed End-of-Arm Tooling (EOAT)

2. 3D Printed Off-Robot Accessories

3. Robot-Tended 3D Printers

4. Robots As 3D Printing Systems

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)