SCHUNK, Inc.

211 Kitty Hawk Drive

Morrisville, NC 27560 US

800-772-4865 | 919-572-2705

us.schunk.com

IS THIS YOUR COMPANY?

Video Gallery

SCHUNK Werkzeughaltersysteme - Basic Segment

Jede spezifische Anwendung stellt andere Ansprüche. Vor allem wenn es um Präzision geht, dürfen keine Kompromisse ...

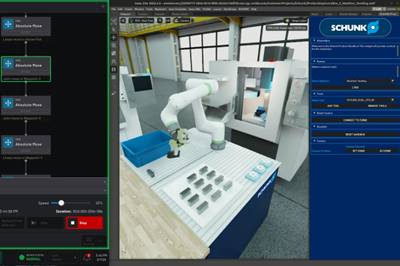

Sortieren von Steckverbindern mit dem 2D Grasping-Kit

Das 2D Grasping-Kit erleichtert den Einstieg in die automatisierte Handhabung mittels Roboter, Greifer und Visionsystem.

Einblicke ins CoLab: SCHUNK R-EMENDO – Anguss entfernen von Stahlgussbauteilen

In dieser Applikation ist der Bearbeitungsprozess Anguss entfernen/schleifen eines Stahlgussbauteils zu sehen. Für diese ...

Einblicke ins CoLab: SCHUNK EGK + AGE-F - Verklemmungsfreies Beladen und Fügen

Mit dieser Applikation möchten wir das verklemmungsfreie Fügen und Beladen bei geringen Einführtoleranzen zeigen. Aufgrund ...

As Seen On Modern Machine Shop

SCHUNK, Inc. Supplies the Following Products

Trade Names Offered by SCHUNK, Inc.

- KONTEC

- PGNplus

- TANDEM

- SINO

- TRIBOS

- PRISMO

- CELSIO

- SRU-plus

- FORTIS

- ACURO

- PZNplus

- SCHUNK VERO-S

- MAGNOS

- ROTA

- SCHUNK

- TENDO