Schunk Partners With Ready Robotics to Develop Simulation Tool

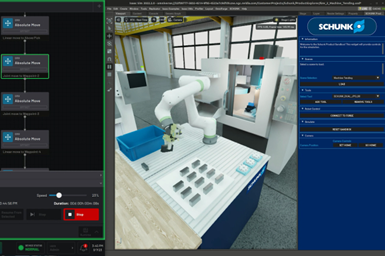

Automation Explorer will enable users to interact with Schunk automation technology in an immersive and detailed, physics-based simulation tool.

Schunk has announced a partnership with Ready Robotics to develop the Automation Explorer simulation tool to support specification, deployment and redeployment of automated systems. Automation Explorer will enable users to virtually experience and interact with Schunk automation technology in an immersive and detailed, physics-based simulation tool.

Nvidia Isaac SimTM, built on Nvidia OmniverseTM, is a simulation platform used to develop, test and deploy AI-based robotics applications. Its physics engine enables detailed, realistic simulations that closely emulate real-world conditions. Ready Robotics is the developer of ForgeOS, the industrial OS for robots and automation, and a developer of automation solutions that are designed to overcome common manufacturing obstacles. Automation Explorer combines Nvidia Isaac SimTM, Ready Robotics’ ForgeOS and Schunk’s automation technologies.

Physics-based technical product data from automation technology, like grippers, will drive the simulation, which will enables virtual commissioning of real-world automation projects. According to Schunk, simulating process automation with physics-based calculations means more accurate visualization and optimization before a robot ever reaches a production floor. Kel Guerin, co-founder and chief innovation officer at Ready Robotics, says, “By connecting ForgeOS and Nvidia Isaac SimTM, customers will be able to control any robotic hardware and Schunk peripherals in simulation and the real world, in exactly the same way.”

“Automation Explorer will bring confidence to both new and experienced users of automation that their process is being optimized to its full potential. Whether investigating automation possibilities for the first time, or redeploying automation equipment for a new task, Automation Explorer brings major opportunity for understanding automation process potential while also digitalizing and simplifying deployment tasks,” says Milton Guerry, president of Schunk USA.

Related Content

-

Using the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

-

Fearless Five-Axis Programming Fosters Shop Growth

Reinvestment in automation has spurred KCS Advanced Machining Service’s growth from prototyping to low-and mid-volume parts. The key to its success? A young staff of talented programmers.

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

.png;maxWidth=300;quality=90)