Seco Tools, LLC

2805 Bellingham Dr.

Troy, MI 48083 US

800-832-8326 | 248-528-5200

secotools.com

IS THIS YOUR COMPANY?

Video Gallery

High-Speed Gear Hobbing with a Seco Indexable Hob Mill | Seco Tools

In collaboration with leading gear hobbing machine manufacturer, Comur, the Seco indexable hob mill was put to the test in a ...

Seco’s X-tra Long Drills Excel at Deep Hole Drilling

shorts The Seco X-tra Long drills are known for their symmetrical point geometries and exceptional heat resistance, which not only ...

Optimized Gear Shaft Turning with Different Geometries: C vs R & T Styles | Seco Tools

In this video, we explore the use of different geometries for turning gear shafts made from H3 tool steel (16 MnCr 5 with a ...

The fascinating tale of microseconds and micrometres, and machining quality

Machining Quality is the degree to which the machining process and system create parts that conform to established technical and ...

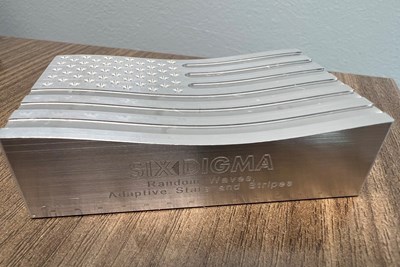

As Seen On Modern Machine Shop

Seco Tools, LLC Supplies the Following Products

Trade Names Offered by Seco Tools, LLC

- Radiabore®

- Nanofix™

- Secomax®

- Square 6™

- Shrinkloc™

- Double Octomill™

- Toolperf™

- Combimaster®

- Librabore®

- Seco Plus™

- Nanobore®

- Kegel/Flansch®

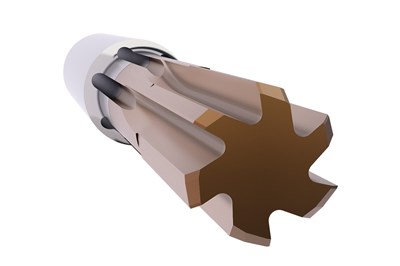

- Crownloc®

- Seco Application Suite™

- Seco-Kestak™

- Precifix™

- Seco Guide™

- Carboloy®

- Indusetter®

- Seco®

- Jetstream Tooling™

- Secotools®

- Minimaster®

- Xfix™

- Twin Threader®

- Alg®

- Seco High Feed 2™

- Mini-Shaft™

- Threadmaster™

- Axialibrabore™

- Jabro™

- Seco-Capto™

- Rigid-Fit™

- Libraflex®

- Seco High Feed 6™

- Epb®

- Graflex®

- Jabro™-Solid2

- Seconomy™

- Seco Point™

- Balansetter®

- Jumbobore®

- Bifix®

- Hexamill®

- Nano Turbo™

- Liteline™

- Monobloc™

- Crownloc® Plus

- Steadyline™

- Axiaset™

- Induflex®

- Duratomic®

- Octomill®

- Pramet®

- Cone/Face®

- Seco Feedmax™

- Seco Threading Wizard™

- St Snap-Tap™

- Perfomax®

- Power 4™

- Seco High Feed 4™

- Snap-Tap®

- Precimaster™

- Axiabore®

- Easyshrink®

- Quattromill®

- Minimaster® Plus

- Seco Device™

- Seco Cut™

- Solidmaster®

- Secolor®