GibbsCAM

2545 W. Hillcrest Drive

Suite 210

Thousand Oaks, CA 91320 US

805-523-0004

gibbscam.com

IS THIS YOUR COMPANY?

As Seen On Modern Machine Shop

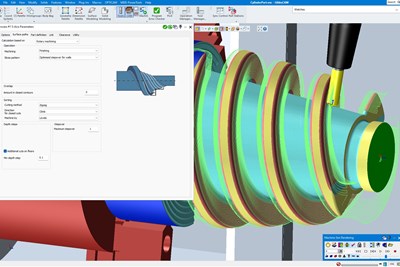

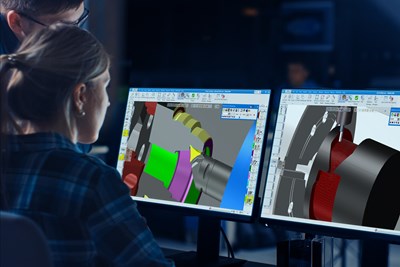

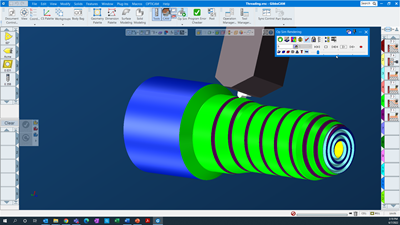

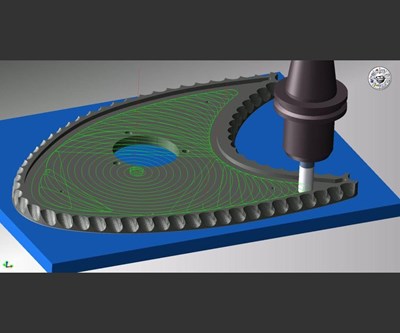

GibbsCAM Supplies the Following Products

Trade Names Offered by GibbsCAM

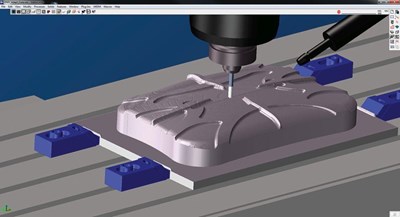

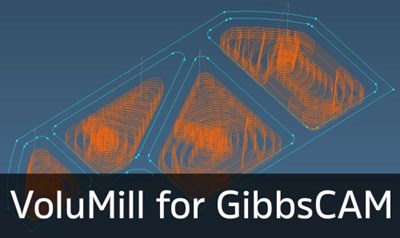

- GibbsCAM VoluMill Solids (3-Axis)

- GibbsCAM High-Speed Machining

- GibbsCAM

- Rhino Add-In for GibbsCAM

- SolidSurfacer

- GibbsCAM Polar& Cylindrical Milling

- Virtual Gibbs

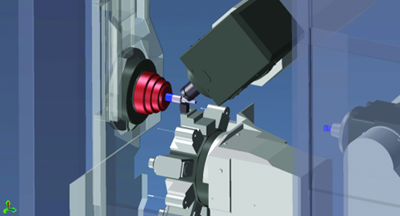

- GibbsCAM MTM (Multi-Task Machining)

- GibbsCAM Radial Milling

- GibbsCAM VoluMill Wire (2-Axis)

- GibbsCAM TMS (Tombstone Management System)

- GibbsCAM UKM

- PostHASTE for GibbsCAM

- GibbsCAM CUTDATA

- GibbsCAM Machine Simulation

- GibbsCAM Cut Part Rendering

- Inventor Add-In for GibbsCAM

- Solid Edge Add-In for GibbsCAM

- Gibbs

- GibbsCAM UKM

- SolidWorks Add-In for GibbsCAM

- GibbsCAM SolidSurfacer

- CAMBRIO

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)