Sodick, Inc.

601 Commerce Drive

Schaumburg, IL 60173 US

847-310-9000

sodick.com

IS THIS YOUR COMPANY?

Video Gallery

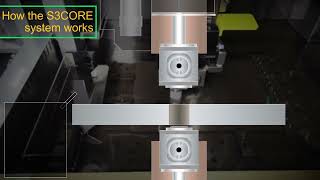

S3Core by Sodick

Sodick Smart Site | Automation Cell

Depicted here is a machine tool automation cell with a Sodick Sinker EDM and High Speed Mill.

Sodick Inc. EDM Company

Hear about the United States branch of Sodick.

VN Series | Wire EDM by Sodick

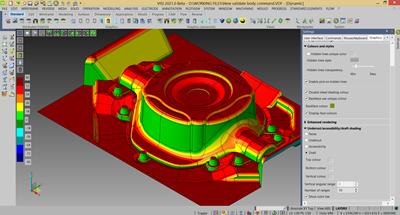

The new Sodick VN Wire EDM Series.