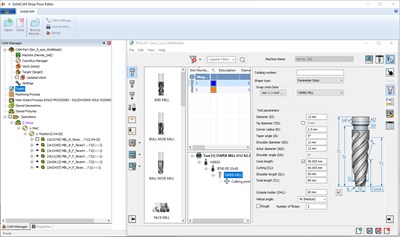

SolidCAM

207 Pheasant Run

Newtown, PA 18940 US

866-975-1115 | 866-975-1115

solidcam.com

About SolidCAM

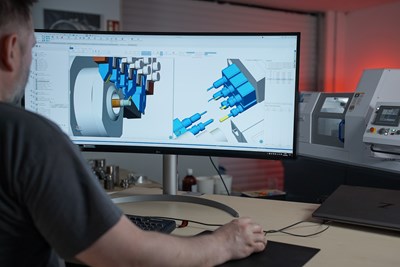

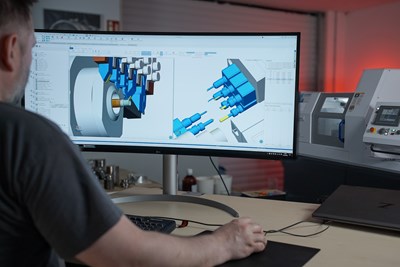

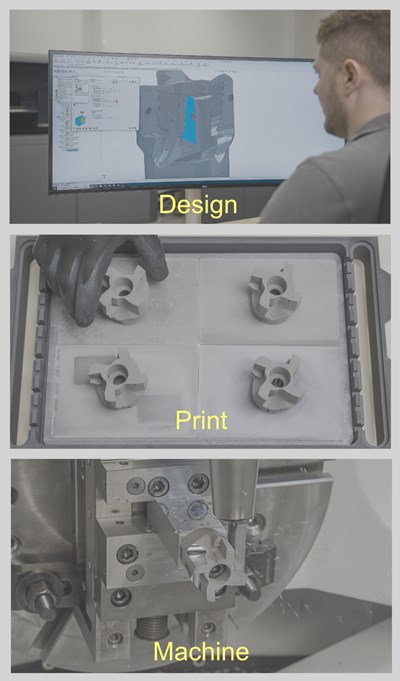

The core strategy of SolidCAM focuses on integration in the leading 3D CAD systems, SOLIDWORKS and Autodesk Inventor. This strategy has created major growth and established SolidCAM as both the leader in Integrated CAM, as well as one of the most powerful CAM systems available.

IS THIS YOUR COMPANY?

Video Gallery

Swiss CNC Engraving with SolidCAM

SolidCAM provides powerful programming tools that are easy to learn and use, covering the full range of 4/5-Axis Simultaneous ...

Linda's Corner - Interview with Daniel Santos

Join us for the next episode of Linda Somekh's Podcast – Linda's Corner, where we delve into the fascinating world of digital ...

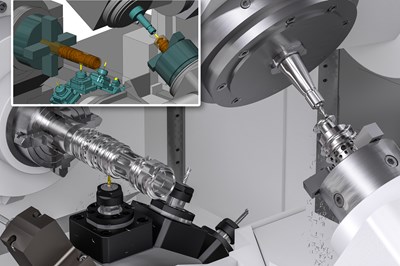

SolidCAM 5-Axis CNC Milling

CAM programming by SolidCAM. SolidCAM has the most tested and proven 5-axis machining toolpaths in the industry! Visit our ...

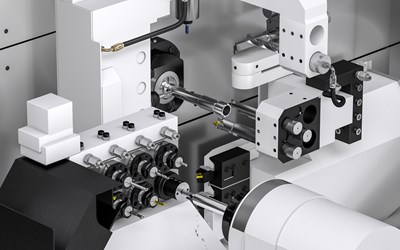

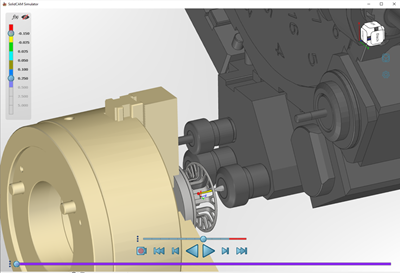

SolidCAM Swiss Machining on a Star ST-20

SolidCAM is the perfect solution for your current or future multi-tasking machining needs, with ultimate programming flexibility and ...

As Seen On Modern Machine Shop

SolidCAM Supplies the Following Products

Trade Names Offered by SolidCAM

- SolidCAM

- iMachining

- InventorCAM