Building A Powerful Bridge from the CAM Programmer to the Shop Floor Operator

Sponsored ContentSolidCAM for Operators provides a powerful bridge from CAM programming to the shop floor to best streamline the machine shop process with its CAM part simulation. It provides a clear picture to the operator for setup and prove-out, enables minor G-Code changes and avoids crashes, broken tools and scrapped parts.

Share

It would be great if every new CNC part program ran perfectly without modifications, but that’s often not the case. Operators may have questions about setup, tools may need to be substituted or possibly an error was made in the G-code. Often, operators don’t know if the program is set up correctly and need to perform a dry run to prove it out. They may also need to go back to the CAM department and request changes in the CAM part program. This wastes a lot of time, perhaps some material, and leaves a CNC machine idle until a proven part program can run.

It would be better in this respect if the CAM programmer were tied more closely to the CNC machine. What most shops need is a better bridge between the CAM programmers and the CNC operators that enables the operator to quickly visualize setup requirements, validate part programs, and correct for errors or do modifications to the CNC program.

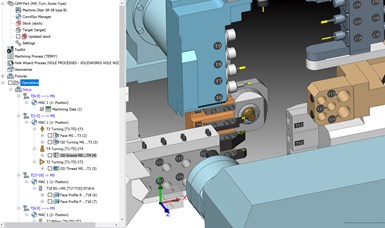

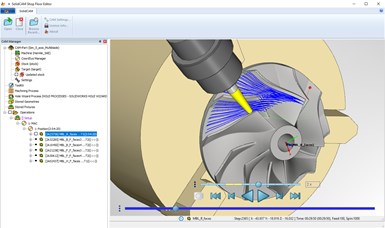

With SolidCAM for Operators, the programmer and operator use the same CAM software, enabling the operator and programmer to see a CAM part program in exactly the same way. It gives operators a full view of solid and machine simulations, enabling them to avoid unexpected crashes or collisions due to programming mistakes. Operators can even make minor adjustments, without relying on the CAM programmer, and they can see all details of each operation, including tools, setup definition, stock clamping, home positions and a complete simulation of the process. Operators can also single-step through each move in the program to reduce setup time, eliminating the need to dry-run programs on the CNC.

SolidCAM for Operators expands SolidCAM’s functionality to the shop floor. SolidCAM is a leading CAM system, seamlessly integrated and associative to the most widely used solid modeling CAD systems, SOLIDWORKS, Solid Edge and Inventor. Users can utilize the leading CAD design programs and simultaneously leverage the same 3D model for advanced CNC programming modules. These modules include SolidCAM's well-regarded iMachining, that provides major cycle time savings with optimized 2D and 3D toolpaths, and its advanced Multi-Channel Mill-Turn and Swiss-Type solutions, offering a simpler and more visual approach to effectively program complex machines.

Three Modes of SolidCAM for Operators

While many shops may not want all their operators editing G-code, all operators can benefit from more explicit and visual setup instructions. But giving editing capabilities to higher-skilled operators can save a great deal of time, and generate worry-free CAM programs. To serve all skill levels, SolidCAM for Operators is offered in three modes:

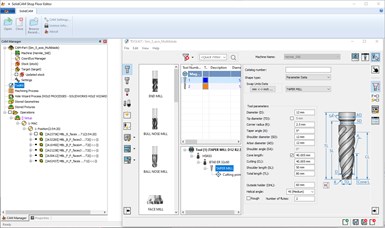

Full Editor Mode enables the CNC operator to open existing CAM parts, edit the operations (for example, change step-down or change feeds and speeds), edit toolkit, view the part setup, recalculate, simulate, then post-process a new G-Code program.

Editor LT Mode enables the CNC operator to open existing CAM parts, edit the feeds and speeds, edit toolkit, view the part setup, recalculate, simulate and then post-process a new G-Code program.

Simulator Mode enables the CNC operator to see the tool table list with full details, understand the clamping and work offsets, and see a simulation of the CAM part before running the program on the CNC machine. Simulator mode does not include CAM part-editing capabilities.

Bring New Efficiency to the Machine Shop

Bottom line, being able to visualize and quickly edit CAM part programs in the shop, reduces setup time with all the benefits that implies — better utilization of machines and labor, and maximizing production. But there are other benefits as well. Working in this way can build a stronger bridge between the operators and the CAM programmers, eliminates the need for dry runs in many cases, prevents crashes, broken tools and scrapped parts, and helps upgrade operator skills.

According to SolidCAM CEO and founder, Dr. Emil Somekh, “SolidCAM for Operators is an essential tool for the CNC operator and greatly assists the machine shop to streamline their manufacturing processes. SolidCAM for Operators bridges the work of SolidCAM CAM Programmers and the CNC machine Operators. By using the same software, it enables the operator to see what the CAM Programmer sees, and to edit when needed.”

For more information, please visit SolidCAM for Operators.