A Closer Look At Look-Ahead

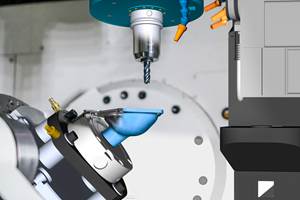

This CNC capability is helping make machine tools move far faster, and more accurately, than ever before. Here's how it works.

Is it possible that your existing fast CNC mills can mill your same 3D contours in 1/10th the time? Not just 10 percent faster, but ten times faster? Is it possible that the part could be even more accurate at the same time? The answer to these questions is a definitive yes from people who daily use controls featuring look-ahead. Some are more conservative, citing three to five times the improvements, but in competitive industries like molds, dies, patterns and prototypes, the ability to mill accurate part surfaces in a small fraction of the historic time is still exciting.

If you mill 3D surfaces from CAD/CAM data, look-ahead may be the single greatest productivity feature your CNC control can (or may not) offer. Look-ahead for 3D milling may be referred to as "automatic feed rate override," "geometric intelligence" or other things, but the bottom line is that look-ahead can improve your overall milling productivity dramatically.

"You can't talk about high speed without look-ahead," says Dave Long, of Pro-Mold, Schaumburg, Illinois. "We bought our latest CNC machining center with feed rates to 600 inches per minute (ipm) based on the promise of high speed. We haven't realized the benefit from that machine, though, because it doesn't have look-ahead. The addition of new high speed controls with look-ahead on four of our older machines has actually relegated our newest machine to mundane, slower work. The oldest machines all outperform the newest, primarily because of look-ahead." The importance of look-ahead is emphasized by the fact that Pro-Mold now mills 3D surfaces on a former tracing mill with a maximum 100 ipm feed rate. It can mill the same part as the newer and "faster" machining center in a fraction of the time, because of the look-ahead. A 100 ipm machine with look-ahead is actually faster than a 600 ipm machine without look-ahead. Mr. Long's claims of milling that is ten times faster are echoed by Merl Widup of Ehlert Tool, New Berlin, Wisconsin and David Simon of Simco Industries, Roseville, Maryland, and others.

Maximum Feed Rates

Imagine a machine capable of 1200 ipm feed rates milling a part for which total X/Y surface measures only 1/2 inch square. The part isn't large enough to ever accelerate to the machine's maximum of 1200 ipm. Still, if your cutter and material allow cutting at 1200 ipm, why not cut as fast as possible? With look-ahead, the machine's CNC controller is responsible for maintaining the feed rate as close to the maximum programmed rate as possible without violation of the part's geometric integrity. The point is that the responsibility for establishing the balance of optimal feed rate for productivity with the required accuracy is no longer in the hands of the programmer or the operator, but rather rests on the computerized control. Imagine an operator capable of adjusting the feed rate override selector more than 2,000 times per second to go fast where possible and to slow down just enough where needed. With a really fast control featuring look-ahead, that is the net effect: the fastest part possible, combined with optimal accuracy.

The Way Things Were

To really understand the challenge, a brief history on look-ahead in CNC can be helpful. As you read, you will see that look-ahead has had different connotations in the CNC industry. Then we'll look at what actually happens with look-ahead while we're milling 3D contours.

When NC and CNC were developed, the idea was to pre-plan each move that an operator made, and cause them to be executed in rapid succession, without the thought, delays, and likelihood of error that accompanies manual operations. I can remember the first time I saw an NC machine drilling and milling a part as I watched in amazement. The same operation by hand would have taken easily 20 times as long, and it wouldn't have been nearly as accurate. It would likely have had errors as well. The finish and detail locations were perfect. Feed rates for each move were identical. Tools lasted longer because of the consistency of their workload. NC brought about a new consistency to machined parts.

As NC developed, a buffer was added to allow the control to read a block of data before it was ready to be executed, thus speeding up operation. This buffer gave a sort of "look-ahead" to anticipate the next move and minimize dwell time before the execution of each move.

Things developed to where NC and CNC controls weren't just "point-to-point," which meant it was limited to linear moves. Rather, they came to have circular contouring, helical contouring, and so on. Dwell at any surface transition became less and less acceptable, so "no-deceleration" codes were added to suppress the normal delay at the end of each surface. No-deceleration modes didn't really look ahead, but allowed for the flow of data without dwells by eliminating the need to really get into an accurate position at the end of one move before continuing on to the next. This created a fluid motion of the machine axes, but introduced inaccuracies.

Cutter compensation developed, allowing controls to "automatically" adjust for worn or re-ground end mills, or even compensate for the entire cutter radius relative to actual part dimensions. This required a different kind of look-ahead to allow the compensation routine to see where the next cutter location would be. This 2D look-ahead for cutter compensation didn't improve speed, but rather eliminated the need to program all tangent surfaces for programs to be compensated.

The 1980s and especially the '90s have brought about a proliferation of really good CAD/CAM, with the ability to easily produce 3D contours of all sorts. Generating 3D surfaces with milling cutters creates new problems for the CNC control, though. These surfaces relegate the CNC to its old-fashioned method of working: point-to-point. The CAD/CAM system creates a fine mesh of points over the surface. The CNC mill must then control the cutter over that contour quickly and accurately to combine productivity and accuracy.

Ideally, the most accurate part comes directly off the machine, with little or no handwork. To achieve this, the cusps are minimized by reducing stepovers to a minimum. That means more cutting time, but less chipload, allowing higher speeds and feeds, especially with the new cutting tools now available. Look-ahead is the essential ingredient in milling controls today to allow fast controls and axis drives to make accurate parts in minimal time.

Look at the changes that have taken place in just the last 20 years:

- Maximum feed rates were 100 ipm; now 600 ipm is common, and 1200 ipm is better.

- Data density of 0.04-inch point departures was close and accurate; now closer than 0.004 inch is common and may even be closer than 0.001 inch.

- Files of 64 kilobytes were very large; now files regularly exceed 10 megabytes (MB) and may exceed even 100 MB.

- Sculptured surfaces were used occasionally for aesthetics; now sculptured surfaces are widely used for both function and appearance.

What's The Problem?

So with the new, fast CNC controls, what is the problem? Most CNC built today can exceed 400 ipm feed rates. That's fast enough for anything, right?

Well, maybe. If all that is needed is to go fast from one location to another for drilling or tapping, or milling long segments, fine. Simply going fast may be enough. Again though, in 3D contours, the shape comes from many points close together. That is the problem--the close points. To look at a photo of a mold core for a Kirby vacuum cleaner gearbox housing. Now look at a wireframe view with a mesh of cutterpath points laid over it. To make the concept clear, the wireframe view shows a coarse cutterpath gridwork, but in reality, we need to make the mesh quite tight to get the finish and accuracy for minimum handwork parts.

From a cross-sectional view, about midway through the part, picked at random, the cutterpath quickly demonstrated just how "real-world" the problems we are talking about really are. The transition area has a "bunching" of data points. These have slight transitions that must occur in very rapid succession. The cutter travels from left to right. Within the detail area, there are 19 points. Three of those points define moves of just 0.0001 inch. Seven points describe moves of 0.0015 inch or less. Nine points describe moves of under 0.003 inch. Indeed, half of the data to describe a transition over just 1.25 inches of linear travel calls for moves of less than 0.003 inch. Here's the actual program data for that area, exactly as generated by a CAM system with a 0.0001-inch deviation specified for accuracy.

(slice at y-.5375)

| N2056X-2.0515Z.6047 | N2057Z.6048 | N2058X-2.0501Z.6047 | N2059X-1.7207 |

| N2060X-1.7094Z.6048 | N2061X-1.6981Z.6047 | N2062X-1.1469 | |

| N2063X-1.1455Z.6048 | N2064X-1.1426Z.6046 | N2065Z.6047 | |

| N2066X-1.1092 | N2067X-1.1078Z.6048 | N2068X-1.105Z.6046 | |

| N2069Z.6047 | N2070X-.9047Z.6048 | N2071X-.8653Z.6047 | |

| N2072X-.8638Z.6048 | N2073X-.8624Z.6047 | N2074X-.8392 |

This bunching of data provides a high likelihood of gouging, and this is common to many detail areas in precision cutterpaths. In a sample cutting area where gouging is likely to occur without the benefit of look-ahead, you may see certain items.

Looking ahead just one block, as with most contemporary CNCs, the machine has just one block's distance to decelerate the entire machine the needed amount. If we're indeed traveling at feed rates of 200 ipm or more, decelerating to 0 in just 0.01 inch or less is virtually impossible. A gouge will occur unless the control is prepared for this contingency with look-ahead.

Another common problem without look-ahead is corner rounding. In this case, sharp corners are rounded by the control's efforts to execute data fast enough, going on to execute one move before its predecessor is complete. Mike Janes, vice president of Damick Enterprises, Rochester Hills, Michigan reports that before adding a high speed control with look-ahead to his Tarus finishing mill, corners were frequently rounded by 0.003 to 0.005 inch. "That was when we milled at 40 to 60 inches per minute with the old control," he says. "Now we mill accurate parts with sharp corners at feed rates consistently around 150 inches per minute."

How It Works

Look-ahead does just what its name implies; it looks ahead of the data it needs to mill at any given moment to verify that the CNC will be able to handle the demands the path will put on the machine. If the data check reveals that there may be a problem, feed rates for intermediate points along the contour are added, adjusting the feed rate downward to the maximum feed rate that will still yield an accurate surface.

Look-ahead must evaluate the data ahead in several different ways. The most obvious check is whether the next point location deviates from the current path. In the simplest case, if the next point simply extends the current path further along a line and there is no deviation, no deceleration is required. Likewise, if the next point is at a 90-degree deviation from the current path, the axis must be stopped completely.

With today's dense data for 3D forms, the overall problem is not so simple. Milling data points that are only 0.004 inch apart at 400 ipm feed rates can really get a CNC into trouble. To stop from 400 ipm, a typical machine might require 0.4 inch. This means that 100 blocks of CNC data must be checked to foresee vector changes. Each point and each combination of points between the current point and the maximum deceleration distance for each axis must be checked. Each tiny move between here and there may need a different feed rate to be calculated to press the performance envelope for speed while maintaining the part integrity. No set rule exists to say that X number of blocks is enough to look ahead. The amount of look-ahead required is dynamic, changing with different part details, different accuracy requirements, different machine performance and so on. However complex this data evaluation is, though, the faster and more thorough it is, the better the CNC can walk the fine line of performance and accuracy. In any case, it must all work transparently for the operator, without any penalty of time or effort. The operator should not be able to cause any violation through program input or operational oversight.

Acc And Dec

Milling machines vary widely in their ability to accelerate and decelerate. For discussion purposes, we often talk about acceleration/deceleration distances of 0.1 inch per each 100 ipm of feed. That infers that at 300 ipm, for example, the acceleration/deceleration distance would be 0.3 inch. Imagine then that we are milling a slice of data. We zoom along through the straight section at 200 ipm, encounter the points leading up to the sharp corner, and then make an abrupt change in direction, requiring that the X axis stop in just a 0.004-inch distance. Without look-ahead, the result might be a 0.19-inch gouge or more.

"With conventional controls, the feed rate is nearly constant," says Mr. Long of Pro-Mold. "You can't run any faster than the slowest wall that you will encounter. If you have a wall that will overshoot at feed rates over 15 inches per minute, you basically have to run the whole job at 15 inches per minute. With look-ahead, the control is constantly adjusting the feed rate to balance speed and accuracy." That makes better parts.

To gain speed and still maintain accuracy on machines without look-ahead, many companies employ "manual look-ahead," using the machine operator to manually adjust the feed rate override selector to slow down for detail areas. Using their high speed controls with look-ahead, Pro-Mold often uses just one operator for three machines. Look-ahead actually evaluates the data far in advance and adjusts the feed rates to allow the machine to cut any contour accurately in the least time practical. In spite of any problems with the motor and/or amplifier performance and machine dynamics, the control's look-ahead anticipates the geometry and ensures that the priority of an accurate part is paramount, and the speed is secondary, yet optimal just the same.

Milling the accurate part does takes more time as anyone would expect. Without look-ahead, milling at 300 ipm, the above part took just 3 minutes, 20 seconds. Milling it accurately without look-ahead took 21 minutes, 15 seconds at 20 ipm feed rate. Look-ahead reduced that time to just 7 minutes, 35 seconds. Larger parts with areas where the axes can feed at maximum rates can show even more dramatic results.

Machine Optimization

Recently, there have been new products introduced to add changing feed rates to the CNC program, allowing higher feed rates without the gouging and overshoot. This essentially creates an off-line look-ahead. After creating a cutterpath, that file is processed again by the off-line look-ahead program to add points in between some of the moves and modify feed rates so that the cutterpath can be accurately milled on a lower-performance control. Off-line look-ahead may be combined into products for preprocessing DNC data files, or may even be provided on-line in the DNC system. Although this approach can provide some improvement in overall milling performance, it also creates larger data files with closer points, exacerbating any bottlenecks in the CNC with block execution speed or with the DNC communications link.

All the benefit of look-ahead cannot be realized without the careful optimization of a machine's acceleration/deceleration capabilities. Graphical drive tuning helps the control eke all the performance possible out of any machine's drive system, still taking the individual machine's dynamics into account. A tuning display for a Delta Tau PMAC machine axis controller card is shown. This display helps the installer and the service technician alike to tune the amplifier and motor to optimally follow any commanded motion. Moreover, it is important to use all the performance your machine and drive system has to offer.

It may seem contradictory, but a machine can actually run faster while running smoother. The benefits of graphical drive tuning combined with the intelligence of look-ahead can create a more fluid motion. This improvement over historic straight-line acceleration methods can help a lot. Used in conjunction with look-ahead's anticipation of geometry changes, the machine axes can flow through data, smoothly accelerating for wide open smooth surfaces, and smoothly decelerating for tight, detailed areas. The machine's appearance while running is obviously more pleasing than the bumping and banging that often accompanies a lack of look-ahead. Another side benefit can be extended machine component life. In spite of the higher performance, look-ahead can help your machine perform better and last longer.

High speed communications is an important feature for the CNC to actualize the full benefit of look-ahead. If the CNC program data can't get into the control fast enough, the ability to execute dense data fast and accurately is a non-issue. Recent articles about DNC and networking of CNCs detail the need to get more data into the control faster. As a rule, 3D data closer than 0.02 inch between points requires direct CNC networking or else the bottleneck of DNC will be evident. When DNC is your bottleneck, the control may actually stop to wait for more data, or your axis motion may appear to stutter as the control quickly executes the deprived data it receives.

Who Needs It?

You may say that high speed milling is a lot of hype and you don't need it. Perhaps you need it more than you even know. Even milling in hardened mold and die steels can benefit from high speed milling if you have look-ahead The dwells and abrupt changes in feed rate that occur without look-ahead can be very destructive to high tech tooling. Likewise, any tooling can benefit from better control of consistent feed rates and smoother accelerations. Ralph Oswald of Chicago Mold, St. Charles, Illinois says, "From what we've experienced, you would be picking up at least three times faster, just in your cutting, your time on the machine, even in steel."

During a recent technical seminar, one attendee stated that there wasn't nearly as much need for high speed milling with look-ahead as there was for new end mills capable of drilling hardened mold steels. That is one of the points here. High speed milling with look-ahead can enable you to use the cutter technology available today to better advantage. You can take more fast and light passes which your cutters can take, rather than one heavy, destructive pass. With effective high speed and look-ahead, your milling times can improve in spite of the extra distances traveled by the machine, your cutters can last longer, and your part can be more accurate. Even in tough steels and alloys, look-ahead is a key to competing today.

Milling and finishing 3D surfaces may be one of the great bottlenecks in your end product. Look-ahead can be the CNC feature that enables you to maximize your investment in your milling machines. Perhaps you have enough milling capacity, but can't get the surfaces polished fast enough. Look-ahead gives you the tool to mill faster with finer increments to reduce or even eliminate polishing. With look-ahead, you will be able to produce better parts in less time.

Click here for more information about Geonics, Inc. / Creative Evolution CNC.

Related Content

Finally, A Comprehensive Software Solution Designed for Small Job Shops

Zel X from Siemens is an integrated software application that consolidates collaboration, design, manufacturing, and operations into a comprehensive, easy-to-use solution. From RFQ to delivery, it’s a more efficient way to handle quotes, manage jobs, make parts, and collaborate with teams of all sizes.

Read MoreImprove Machining Efficiency Through Digital Twin Simulation

Full simulation of a machining cycle using digital twins can not only identify crashes before they happen, but provide insights that enable the user to reduce cycle times.

Read MoreIMTS Takeaways From the Modern Machine Shop Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

Read MoreBuilding A Powerful Bridge from the CAM Programmer to the Shop Floor Operator

SolidCAM for Operators provides a powerful bridge from CAM programming to the shop floor to best streamline the machine shop process with its CAM part simulation. It provides a clear picture to the operator for setup and prove-out, enables minor G-Code changes and avoids crashes, broken tools and scrapped parts.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)