Tooling

Latest Tooling News And Updates

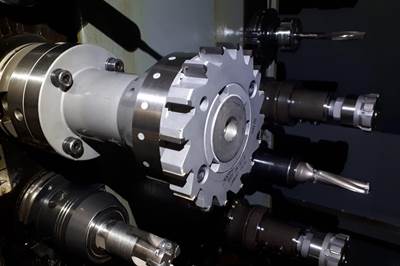

Ceratizit Milling Cutter Line Enhances Superalloy Machining

Ceratizit USA Inc. updates the MonsterMill ISO-S series with a six-flute cutter for improved surface finishes and efficiency in nickel- and titanium-based alloy machining.

Read MoreRoughing First: New Strategies for Blisk Machining

Aerospace shops looking to cut cycle time and tool wear on integrally bladed rotors often focus on finishing. But rethinking the roughing stage can increase how much material can be safely removed while accelerating throughput.

Read MoreJergens Spindle Gripper Supports Unattended Machining

Jergens Inc.’s MT-S Spindle Gripper is designed to enhance machine utilization.

Read MoreTJ Davies Coolant Tubes Enhance Toolholder Performance

TJ Davies Co. Inc.’s line of coolant tubes and wrenches designed for HSK toolholders are available in sizes from HSK-25 to HSK-125.

Read MoreReducing Chatter and Strain Through Pressure Monitoring

Loss of fixture pressure can cause problems from chatter to thrown parts. Pressure monitoring helps keep fixtures stable and operations on target.

Read MoreSeco Drill Provides High-Feed Performance

The Seco X-Tip Drill features a high-feed geometry provides faster, cleaner holes with less downtime, while its recyclable tips support sustainability goals.

Read MoreFeatured Posts

Can Cooperation Out-Compete Competition?

Spearheaded by Rego-Fix, the Center for Machining Excellence gives OEMs the chance to cooperate and provide a more comprehensive service to their customers, and it gives machine tool users the chance to look at all the component elements that go into a machining cell.

Read MoreGet a Grip on Your Workholding Processes

From adhesive fixturing to automated changeovers, these articles show how shops are rethinking workholding to improve efficiency and accuracy. Whether it's collet choice, custom fixtures, or balancing density with simplicity, smarter setups are driving better results.

Read MoreFrom Manual Mills to Hybrid CNC: How Conversational Control Transformed Toolroom Machining

When a veteran machinist refused to use a new CNC mill, his resistance sparked a revolution. This article traces how Southwestern Industries developed ProtoTRAK — an intuitive hybrid control system that remains vital as AI begins reshaping manufacturing.

Read MoreUnderstanding Process Damping in Milling Operations

Despite the advances in modeling machining operations over the past decades, process damping remains a topic of interest, including new tool designs that increase the effect.

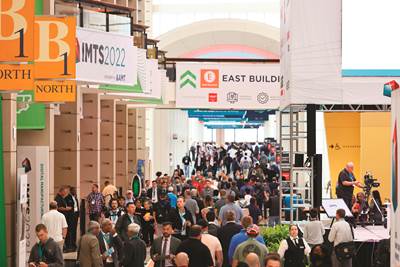

Read MoreNew Possibilities from Process Consolidation, Customization, AI and More at MT Technology Series East 2025

When do broadening capabilities outweigh specialization (and vice versa)? In our recap of MT Technology Series East 2025, find out how the latest generation of machines, tooling and software answers that question.

Read MoreA New Frontier in Surface Finish Control

What if your machine tool could measure surface roughness as it cuts? This article explores how in-process metrology is advancing from concept to reality, enabling real-time feedback, immediate detection of anomalies and new levels of control over surface quality. Discover the technologies making this possible.

Read More