Preventing Spindle Crashes with Digital Twins

With only four machine tools, high-mix shop Novo Modo needed a surefire way to prove out programs and prevent spindle crashes. But when it adopted a CAD/CAM software with digital twin simulation capabilities, it found that its benefits ran even deeper than anticipated.

Share

Four Hermle five-axis machines, four Wenzel CMMs and carefully chosen Fraisa cutting tools: Novo Modo Machining, a small job shop in Mount Vernon, Washington, keeps its shop floor lean and standardized. Any job must be able to work on any of the shop’s four machines, and its high-mix environment makes it vital to get the process right the first time. But how does it accomplish this? Founder Joseph Alonso gives a large portion of the credit to the digital twin simulation capabilities and other features of its CAM software, HyperMill.

Joseph Alonso founded Novo Modo to be a small, agile shop with standardized work cells. The shop currently operates four work cells with five-axis machines in 3,500 square feet of space. Images courtesy of Novo Modo.

New Tools for a New Paradigm

Alonso aims for Novo Modo to be the first in a line of small, tightly focused, completely standardized shops. When he founded the company in 2023, he searched for machining technologies and brands that would help him accomplish this goal. While he was set on five-axis mills early, achieving tight tolerances across a high-mix workload of aerospace, defense and space parts required powerful CAM software that would enable him and his employees to work faster than he could with the CAM software he was accustomed to using.

Open Mind Technologies approached Alonso and offered to let him try HyperMill, its CAD/CAM software. After consulting with peers familiar with the software — specifically to ask how it performed in preventing crashes with five-axis mills, as machine crashes would be especially ruinous for a lean shop — he took the company up on its offer.

Alonso ran one test job with HyperMill and decided to stick with the software for the long haul. He says its workflow matches his own process, making it intuitive for him, and its digital twin capability eliminates most of the risk from his part programs. “As long as my feeds, speeds and depth of cut are all correct, I’m going to have a good part without a machine crash,” he says. Two years after adopting the software, Novo Modo has created over 300 CAM projects in the software and never suffered a spindle crash. This consistent success gives Alonso and his team the security of mind to focus on business concerns and value-adding tasks on the shop floor, rather than forcing them to watch the machine tools at every moment.

The software has also decreased the time to program parts, Alonso says. While the CAM software he used in previous jobs often required him to spend upward of an hour to create successful tool paths, he rarely spends more than 20 minutes on even a complex tool path with the new software. This speed has kept the shop’s lead times short, with Alonso saying the ability to program quickly and prove out parts before they hit the machine enables the shop to manufacture five-axis prototypes with over one hundred key dimensions in only a few days.

Digital Twins and High-Precision Surfaces

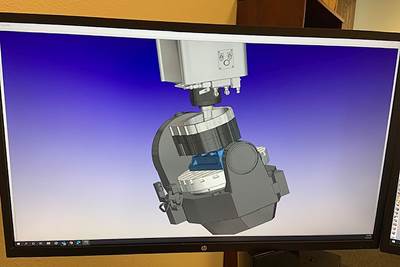

The Virtual Machine function of HyperMill generates NC code and simulates it using a digital twin of the user’s machine. Alonso says this feature saves time by eliminating programming issues at the machine while also heading off many potential tooling and workholding issues before setup occurs.

Alonso says the security provided by simulation helps the shop push cutting parameters on new or reposted jobs. Where before the shop would need to run a part at 10-20% rapid in single-block mode to prove out the process and avoid damaging the part, it can now run the same job at 40-60% rapid, 100% feed rate with optional stops for watching tools start. This change reduces production time by 33%. For reposts with small edits, the shop can even eliminate the stop and run the program at 60-80% rapid, further decreasing production time.

Novo Modo also uses the software’s High-Precision Surface Mode. This mode performs toolpath calculations on the surface of CAD models, rather than a tessellated approximation of the surface. This improved accuracy helps even when the shop is already in tolerance, as eliminating minor errors enables the machine to move faster. The software also pays careful attention to NC points, both for proper spacing and to protect critical features. In doing so, programs using this mode produce part surfaces with greater fidelity to the design model. Alonso says this careful attention to surfaces greatly improves the consistency of part surface finishes and has eliminated the need to perform secondary finishing operations like deburring and polishing. This cuts part production times and ensures the Novo Modo team can spend more time at other tasks.

By combining Virtual Machine and Tool Database in HyperMill, Novo Modo can simulate complex five-axis programs and eliminate the risk of spindle crashes, all while running parts at more efficient cutting parameters.

Building the Database

In addition to using digital twins of machines, Novo Modo uses HyperMill’s Tool Database to provide oversight into cutting parameters and reduce programming time. Alonso imported XML files of Fraisa cutting tool data directly from Fraisa’s ToolExpert into the HyperMill Tool Database. This data includes geometric information as well as recommendations for parameters like speeds, feeds, stepovers and depths of cut.

The shop can save these recommended parameters for specific materials and cutting processes. Programmers can then import these parameters for future jobs, reducing programming time, eliminating manual input errors and democratizing information that may otherwise become tribal knowledge. In Novo Modo’s experience, Alonso says Tool Database typically reduces programming time as much as 10%.

Bringing Tool Database and HyperMill’s other features together, Alonso points to a deep hole drilling application to demonstrate how the CAM software has aided the shop. In this application, the shop needed to drill a 0.125-inch hole with a four-inch depth (32 × diameter). Novo Modo used HyperMill to produce the tool path with optimized cutting parameters for each of the eight distinct process steps. Information from Tool Database helped the shop control break throughs, partial stock conditions and tool movement into and out of the gap, ensuring that these difficult aspects of the application did not damage the tool and risk the job’s profitability.

New Horizons for Novo Modo

Alonso says HyperMill has been particularly useful for new operators. Simulation helps them catch potential errors before they touch a part, and advanced features enable them to perform complex tasks even with little experience. He points to the utility of HyperMill’s five-axis rework function, which takes a three-axis tool path that may not be able to machine certain features due to collision conditions (a steep wall, for example) and automatically creates a five-axis tool path that is able to do so.

The software’s usefulness is not just theory, as Alonso refers to the example of a cavity milling application a 19-year-old operator needed to complete for a five-piece mold. Alonso says the High-Precision Mode in HyperMill gave the operator a leg up in milling the surfaces of the first, most-complex cavity correctly. After successfully producing this cavity, the operator was able to use the data to speed along the creation of part programs for the other four cavities, milling them all successfully on the first try.

Alonso hopes this success will prove to be the norm as he tries to expand Novo Modo with new locations. While he plans to promote some of his more seasoned employees to management positions in these shops, each location would need to train employees new to the machining industry. Through simulation capabilities and the standardization and automation of complex aspects of programming, Alonso believes HyperMill will help these new hires quickly grow their skills while making them more capable from the beginning of their careers — and help Novo Modo reach its goal of 10 new facilities in the next 10 years.

Related Content

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreAI Creates CAD Files From Scan Data

While 3D visual scanners are useful, converting a visual scan to a usable CAD file can be a time-consuming process. With generative AI, it may be much simpler and faster.

Read MoreLarge-Format Machining With Small Cutting Tools and Dynamic Motion

Napoleon Machine, a defense contractor that provides parts for the M1 Abrams tank, recently took advantage of a CAM feature that allowed the company to streamline its cutting strategies and program offline. Here’s how the shop cut cycle times nearly in half with its large-format five-axis machining operations.

Read MoreSolidCAM iMachining and Technology Wizard: Faster Machining and Longer Tool Life

Smarter toolpaths to tackle modern machining challenges.

Read MoreRead Next

Advanced CAMs Simplify Programming of Conical Barrel Cutters

Conical barrel cutters have grown in popularity thanks to the large stepovers that reduce the time needed for some finishing processes, but advanced CAM systems can dramatically improve their usefulness.

Read MoreHyperMill Five-Axis Modules Simplify Complex Part Machining

Open Mind’s HyperMill CAM software includes powerful five-axis milling modules that decrease machining times for complex parts, as happened at NDK Paragon.

Read MoreFive-Axis CAM Strategies Cut Cycle Time for Two Shops

After being acquired by the same parent company, two shops found that working together and sharing knowledge improved both of their bottom lines.

Read More