Anatomy of a New Bond Technology

A new vitrified bond technology features proprietary chemistry to achieve higher performance as well as extended wheel life for today’s advanced grinding machines.

Today’s faster grinding machines are pushing wheel manufacturers to develop new formulas that enable those machines to realize their full production potential. Scott Leonard, director of product management, bonded adhesives for Norton Abrasives (a brand of Saint-Gobain), says the company’s new Norton Vitrium3 vitrified bond technology features proprietary chemistry to achieve higher performance as well as extended wheel life for those advanced machines.

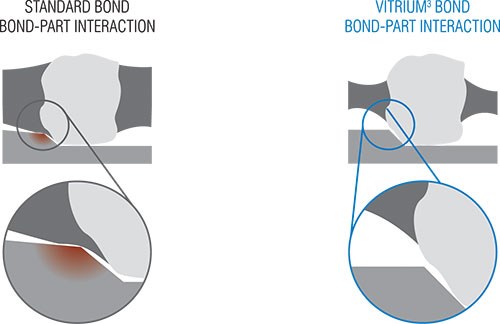

Vitrified wheels have two primary components: abrasives and bond. The abrasives are the wheel’s “cutting tools” and the bond holds the abrasives in a matrix to form the wheel. The space between the abrasives and the bond represents the wheel’s porosity. The Norton Vitrium3 bond features grain-adhesion chemistry that substantially increases the module of elasticity, or strength, of the bond. Therefore, less bond is required to provide the same holding force, and porosity increases.

Mr. Leonard says this offers three key advantages. The first is cooler cutting conditions. Less bond means there’s increased exposure of the abrasives. This results in improved cutting rates and significantly less burn as well as reduced power consumption and grinding forces on the part. Plus, increased porosity improves coolant flow and chip clearance to further reduce burn even on tough-to-grind materials, such as high-nickel-content alloys, tool steels and chrome.

Second, the strong bond offers considerable wheel form and corner holding, which improves part quality and tolerances while reducing dressing time and wear. (This is especially important for applications that have intricate part profiles.) Less frequent wheel dressing reduces grinding downtime, dresser wear and costs for wheels and replacement dressers.

Finally, faster wheel speeds are possible. With 20 percent higher strength than conventional vitrified bonds, Norton Vitrium3 enables softer grades to qualify for high speed grinding. Higher operating speeds provide faster stock removal and feed rates, increasing grinding throughput and production.

Related Content

-

Volumetric Accuracy Is Key to Machining James Webb Telescope

To meet the extreme tolerance of the telescope’s beryllium mirrors, the manufacturer had to rely on stable horizontal machining centers with a high degree of consistency volumetric accuracy.

-

A New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

-

Inside an Amish-Owned Family Machine Shop

Modern Machine Shop took an exclusive behind-the-scenes tour of an Amish-owned machine shop, where advanced machining technologies work alongside old-world traditions.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)