Grinding Cell Yields Automatic Rewards

Sheffield, United Kingdom-based tool manufacturer Universal Drilling and Cutting Equipment (UDCE) manufactures a wide range of products for the engineering, fabrication and construction industries, including electro-magnetic drilling systems, broaching cutters, tungsten carbide cutters, industrial cutters and specialized engineering tools.

Sheffield, United Kingdom-based tool manufacturer Universal Drilling and Cutting Equipment (UDCE) manufactures a wide range of products for the engineering, fabrication and construction industries, including electro-magnetic drilling systems, broaching cutters, tungsten carbide cutters, industrial cutters and specialized engineering tools.

More than a year ago this company began a transfer to automation as sales of its broaching cutters outstripped production. The problem UDCE faced was how to reduce a bottleneck occurring in its cylindrical grinding process, in which three manual machines were each carrying out primary and secondary grinding operations on high speed steel cylindrical blanks. Operation 1 called for the machining of a sleeve and two flats at a 90-degree angle to one another. Operation 2 required the bar to be turned around and gripped from the opposite end and a sleeve to be machined with a 0.25-mm (0.010-inch) taper.

Taking initiative from the automotive industry, Manufacturing Director Brian Gascoyne decided that the way to go forward was through a fully automated grinding cell with automatic loading and lights-out CNC grinding operations. Fully supported by Managing Director Vic Archer, Mr. Gascoyne purchased a combination Jones & Shipman (Meriden, Connecticut) Format 15 cylindrical grinder and Kawasaki (Wixom, Michigan) robot loader.

Initially, manipulating the robot’s twin arms into position to deliver and remove parts from the Format 15’s chuck turned out to be an extremely difficult task. However, after extensive trials, adjustments and re-programming, autoloading was achieved, and with it came considerable improvements in production. As Manufacturing Manager Mick Wood says, “We knew the way forward, however, it took us a long time to get it the way we wanted it.

“Once it was fully commissioned, and we saw the productivity benefits from the Format 15 robot loading setup, we felt that the natural progression would be to carry out both operations simultaneously, through the integration of a second cylindrical grinder into the existing grinding cell,” adds Mr. Wood.

After lengthy discussions with Jones & Shipman’s sales and applications engineers and a review of several competitors’ machines, Mr. Wood became convinced that the Jones & Shipman Ultramat CNC cylindrical grinder was the ideal second machine for the grinding cell. The two Jones & Shipman cylindrical grinders, in harness with the robot loader, have almost doubled productivity of the company’s Unibor range of annular cutters.

The Ultramat CNC, along with the recently introduced microprocessor-based Ultramat Easy Grind, fit neatly into Jones & Shipman’s carefully structured range of cylindrical grinders, combining many of the features of the larger, high production cylindrical grinder, the Supromat, but at a lower price.

Not only is the Ultramat productive, but the company says it is also simple to use. Easy-to-follow Windows setup pages allow the operator to digitize diamond and wheel positions, and, with a minimum of mouse or keyboard inputs, produce a finished program.

Graphical images prompt the operator, and spreadsheet style programming ensures quick and simple input. A GE Fanuc CNC Intelligent Terminal, with associated GE Fanuc digital AC servos, provides the control. All control equipment is housed in an accessible cabinet incorporated into the machine.

“The learning curve we had experienced for the single-grinder configuration really helped us define what we required to integrate the Ultramat, in terms of software programs, I/Os and the robot’s microprocessor control, with help from both Jones & Shipman and the robot installer,” says Mr. Wood.

Now fully productive, the automated grinding cell processes one cutter every minute—the Format 15 carrying out Operation 1 and the Ultramat carrying out Operation 2—with fully automatic loading and unloading from the robot loader. With the grinding cell an unqualified success for UDCE, this booming Sheffield company has other areas of production under review to see if they also will lend themselves to the advantages of automation.

Related Content

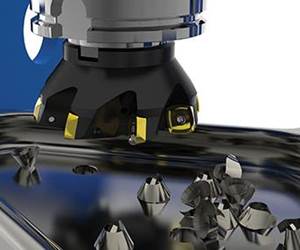

New Modular Tool Options for Small Spindle Milling

Tooling options have been limited for small spindle milling applications. Now modular, indexable systems are available that provide broad flexibility to get the right cutter for the job with less inventory and at lower cost.

Read MoreBest Practices: Machining Difficult Materials

Cutting hardened steel, titanium and other difficult materials requires picking the right tools, eliminating spindle runout and relying on best practices to achieve tight part tolerances.

Read MoreSelecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read More10 Tips for Titanium

Simple process considerations can increase your productivity in milling titanium alloys.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)