Share

It took about two laps around the Automate exhibitors’ space at the Huntington Place convention center in Detroit to realize that the show’s target audience is robotics and systems integrators — tech specialists that develop and implement custom automation solutions for suppliers and OEMs. You couldn’t throw a stick on the show floor without hitting a robot, and if you did, there were silver robotic dogs walking around that would have been happy to fetch it for you.

Companies that offered system integration focused on robotics, automation and vision technologies dominated the show floor. More than any show I’ve witnessed, many of the companies here were actively offering their services to other exhibitors (“let me tell you why your six-axis cobot needs our new line of vacuum end effectors”), but there were plenty of automation solutions available for job-shop owners willing to sacrifice enough shoe leather to search them out.

For anyone who missed the show, here’s a quick glimpse into what I saw.

Wiferion, based out of Munzinger, Germany but with a new North American office in Chicago, offers inductive charging technology for mobile robotics, forklifts and automated guided vehicles (AGVs). Here, vice president of Wiferion North America, Mathhieu Ebert, shows off one of the company’s charging pads. To charge a mobile robot or AGV that has been outfitted with Wiferion technology, the mobile unit simply backs up to the charging pad — a simple contact point that eliminates the need for human intervention in the charging process. (When I explained the tech to my 15-year-old son, he said, “like Baymax from ‘Big Hero 6’?” Pretty close!)

Here, grippers from New Scale Robotics measure the OD of a part while gripping it. New Scale offers automation solutions for part handling and dimensional gaging, and can be used with calipers, height gages, bore gages, thread gages, as well as laser micrometers and vision systems. The tech can be looped into lights-out operations that use this measurement data to set automatic machine tool offsets.

A project eight years in the making, Renishaw debuted its RCS product series. The series includes this RCS L-90 single ballbar kit designed to increase deployment speed of an industrial robot cell by setting tool locations and part frame dimensions more easily and efficiently. The L-90 ballbar feeds back repeatable linear measurements between the robot and its surroundings, and is designed to improve accuracy and monitor robot health. The system is paired with Renishaw’s RCS Software Suite that shows users how to conduct a series of calibration tests.

Meet Jean-Sebastien Neveu, president of Waybo, a system integrator based in Montreal that helps shops deploy robotic cells and increase production efficiency. Here, Jean-Sebastien talks about Waybo’s new machine-shop automation solution that utilizes a Kuka Robotics’ mobile platform and robot to move materials and parts between a (simulated) machine tool, a CMM and a laser marking station.

Perhaps the most futuristic-looking piece of hardware at the event (alas, robot dogs) was Creaform’s MetraScan 3D optical CMM scanner mounted on a FANUC cobot. The device, which can also be handheld, scans and takes optical contact or probe measurements that can be integrated into a lights-out workflow.

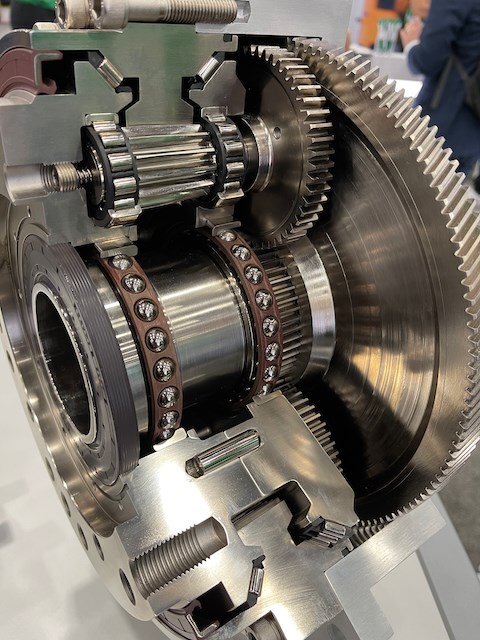

An open view of Schaeffler’s PSC (precise, silent, constant) planetary gear unit. The PSC gear units, which Schaeffler offers in nine sizes and include a patented tooth system with minimal torsional backlash, are available as mounting kits or can be integrated into a customer design. These units are designed for robots with payloads of up to 100 kg.

Here I allowed myself to be bludgeoned by a robot to showcase new technology from Blue Danube Robotics called AirSkin. The product is a modular add-on for cobots and robots that consists of soft, rubbery pads (some created via injection molding and some by 3D printing) outfitted with a number of sensors, or “smart safety electronics.” These pads detect any collisions with the robot and bring it to a protective stop.

WHO DEY! WHO DEY! WHO DEY THINK GONNA SCAN THAT HELMET! Of the several 3D scanning providers at Automate, Photoneo was the only company with the good sense to include what is indisputably the coolest helmet in the NFL. Here, the company’s PhoXi 3D scanner, mounted to a cobot, displays a structured light projection on the helmet and outputs a precise point cloud in high resolution.

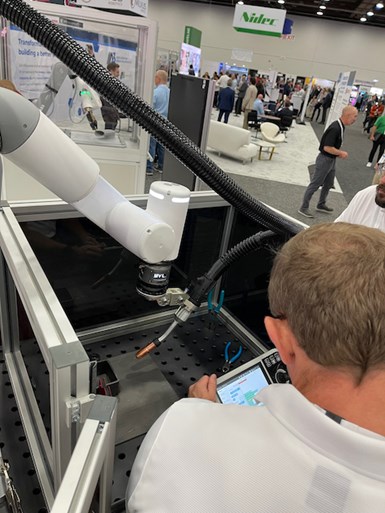

On the left, collaborative arc welding from ABB Inc. using its GoFa cobot. Users can manipulate the cobot arm to form the desired weld path, or use the “Wizard” graphical programming interface.

This graphical interface breaks the code into multi-colored blocks that can be selected from a menu on the tablet then drag-and-dropped into the desired section of the program. The company says that even first-time programs can intuitively program the cobot with the system, and based on the demo I watched at Automate, that assessment was accurate.

Metalworking specialists from Suhner showcased the company’s EFC-02 robot end effector for robotic grinding, sanding and polishing. The EFC is fully electric (it stands for electric force compliance), and takes real-time, high-frequency measurements of acceleration and force. The company says these real-time measurements allow the tool to dynamically adjust its force across changing surface conditions and effectively automates the grinding process.

There are plenty of shops that perform grinding, deburring and polishing by hand, and plenty of operators at risk of work-related musculoskeletal disorders (MSDs). Ironhand — the robotic gloves pictured here from the company Bioservo Technologies — provide grip strengthening through artificial tendons in the fingers that can be configured to the exact force, sensitivity and “locking tendency” needed for any particular task. This enables the wearer to use less grip force and thus reduce the risk of an MSD injury. The gloves receive power from a battery pack worn on the hip or back, and the gloves’ motion can be monitored and activated through an app that uses machine learning to adopt the behavior of the glove to the user’s hand during each task.

About those robot dogs: Here’s a two-minute video and unintentional interview with one of the two humans operating the dogs. (Turn the sound up to hear the conversation clearly.) These “intelligence bionic quadruped robots” made by Unitree are packed with technology, including light detection and ranging (LIDAR) that can create a 3D map of a facility to track and report any discrepancies like an oil spill. Or, mount a thermal camera to ensure your machines aren’t overheating. Or, activate the unit’s “intelligent side following system” — known as “heeling” in canine parlance — to walk around your neighborhood with it and act like you have Jeff Bezos-level money.

Related Content

The Four Phases of a Manufacturer’s Automation Evolution

With more and more automation options available for manufacturers, how do shops figure out what works best? Medical manufacturer rms Company has acquired robot arms, AGVs, pallet changers and software, and while it has found success with all, it has learned how some solutions meet its particular needs better than others.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreUsing Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Read More3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

Read More

.png;maxWidth=300;quality=90)