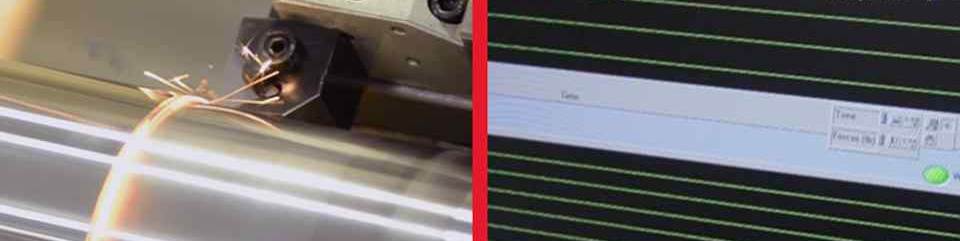

I had the chance to work with TechSolve, the machining consulting firm based in Cincinnati, Ohio, on filming some really ugly machining passes.

The point was cutting force analysis. Watching poorly performing cuts while also seeing the corresponding cutting force profiles illustrates what force measurement can reveal about the process. In many cases, force monitoring is limited to the machine’s spindle-load monitor, but TechSolve can bring more than this. It can measure forces more specifically and directly using a three-component dynamometer.

Force analysis can be useful for diagnosing the challenges of an application involving a difficult workpiece material and/or an unstable process. To the knowledgeable observer, force profiles can reveal the problem areas in a process—the shortcomings to address to make the process consistent and reliable enough for unattended machining.

In this video of machining 4140 steel, watch the cuts and see the force profiles corresponding to (1) gradual tool failure, (2) cutting with a rake angle that is too highly positive for the process and (3) the development of a built-up edge.

Related Content

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

-

How to Tackle Tough Angled Pocket Milling With Two Tools

Milling a deep pocket with a tight corner radius comes with unique challenges, but using both a flat bottom drill and a necked-down finishing tool can help.

-

10 Tips for Titanium

Simple process considerations can increase your productivity in milling titanium alloys.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)