CNC Simulation Software Uses Data for Smarter Manufacturing

The latest version of CNC simulation software incorporates enhancements and new features focusing on using data for smarter, more informed manufacturing.

Photo Credit: CGTech

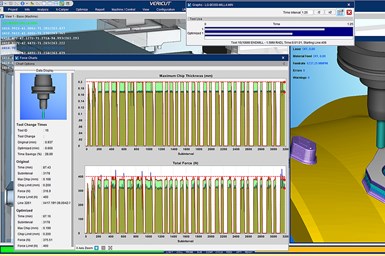

CGTech’s Vericut 9.3 is the latest version of its CNC simulation software, which is focused on establishing smarter, more efficient manufacturing processes by incorporating data from the machine, tools and stock material to improve the quality of the simulation and enable more informed decisions throughout the manufacturing workflow.

The software is said to include improvements to its core features, including improved collision checking, higher limits on axes per subsystem and more. Some of the improvements benefit additional, optional modules such as those for additive simulation and optimization, the company says. With the additive module, shops can simulate, validate and verify NC programs in any order of additive and traditional machining to ensure that all setups and holding fixtures will work. The software verifies laser activity, power, material feed and gas flow to prevent voids and misplaced material, while preventing collisions between the hybrid machine with the additive part.

The software’s Force optimization module has also received additional features and enhancements, with improvements to deflection calculations and the ability to add volume removal rates (VRR) as a limit during optimization for traditional, subtractive machining operations.

Related Content

-

When Handing Down the Family Machine Shop is as Complex as a Swiss-Turned Part

The transition into Swiss-type machining at Deking Screw Products required more than just a shift in production operations. It required a new mindset and a new way of running the family-owned business. Hardest of all, it required that one generation let go, and allow a new one to step in.

-

Swiss-Type Control Uses CNC Data to Improve Efficiency

Advanced controls for Swiss-type CNC lathes uses machine data to prevent tool collisions, saving setup time and scrap costs.

-

From Tradition to Transformation: Century-Old Manual Machine Shop Adds CNCs

After 122 years of working with manual mills and lathes, this fifth-generation shop acquired assets of a local CNC machining business and hired the owner. Here’s how it’s going a year later.

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)