Lantek Bevel Module Streamlines CAD/CAM Programming

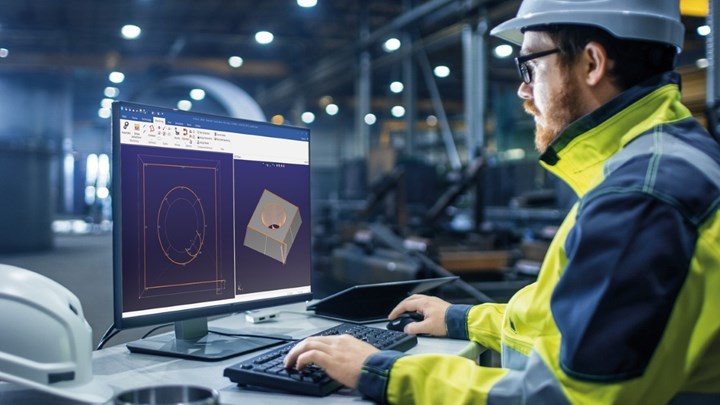

The EdgeLine Bevel module simplifies programming and streamlines CNC programming of modern Trumpf cutting machines for more efficient laser machining.

Lantek Systems Inc., a provider of software solutions for the sheet metal and manufacturing industries, has announced the launch of a new module for its Lantek Expert Cut CAD/CAM nesting software. The EdgeLine Bevel module is designed to streamline the CNC programming of modern Trumpf cutting machines, providing a more efficient and simplified process for laser machining and the preparation of components for welding operations.

The EdgeLine Bevel technology offers several advantages over traditional methods that allow specific beveling techniques to be performed without tilting the laser head, reducing overall processing time, and eliminating the need for separate work center processes. The technology also has a significant impact on the preparation of components for welding techniques by enabling the automatic insertion of chamfers and countersinks of various sizes up to 45 degrees, providing a faster and more efficient process with fewer errors compared to traditional manual methods.

“We are delighted to launch the EdgeLine Bevel module for Lantek Expert Cut,” says Mario Rodríguez, product manager of Lantek. “This technology represents a major advancement in the field of laser processing and will significantly improve the efficiency and convenience of the manufacturing process. We're confident that our customers will appreciate the benefits of this module and that it will help them to stay ahead of the competition.”

The EdgeLine Bevel module is currently available only for modern Trumpf’s laser machines.

Related Content

-

When Handing Down the Family Machine Shop is as Complex as a Swiss-Turned Part

The transition into Swiss-type machining at Deking Screw Products required more than just a shift in production operations. It required a new mindset and a new way of running the family-owned business. Hardest of all, it required that one generation let go, and allow a new one to step in.

-

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

.jpg;maxWidth=300;quality=90)