MMS Blog

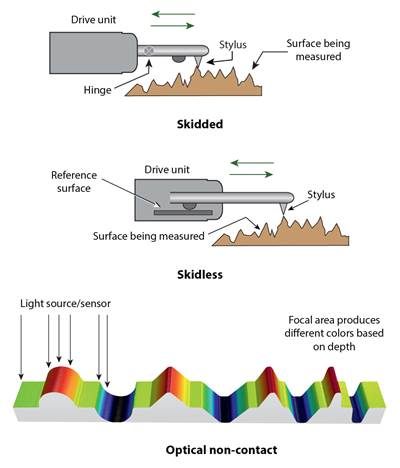

Correlation Between Contact and Non-Contact Surface Analysis Equipment Is Critical — Until It Isn’t

Understanding the differences between measurement methods means their discrepancies can be explained and used as an advantage to produce better correlation.

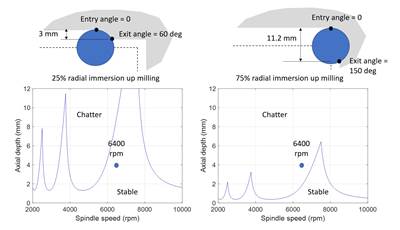

Read MoreMachining is More Than Geometry

While CAD/CAM software may represent machining operations as geometry, you must consider vibration effects to obtain a successful outcome.

Read MoreSpatial Computing, AI Meet the Machine Shop

Artificial intelligence and the spatial computer have enormous potential to change the way machine shops will operate in the future.

Read MoreEmbracing Automation: Strategies for Small to Medium-Sized Machine Shops

Business drivers for automating to help navigate workforce challenges and boost profitability.

Read MoreThe Intersection of CMMC and Small- to Mid-Sized CNC Job Shops

The decision to gain or retain status as a defense supplier by pursuing CMMC compliance is especially difficult for small- to mid-sized machine shops, and the complexities and misperceptions tied to the program certainly aren’t helping. To break down those complexities, here are five key issues that small- and mid-sized job shops need to know about CMMC.

Read MoreThe Softer Side of Robots: Increasing Automation’s Adaptability

Robotic applications are expanding thanks to rubber and silicone-based systems that can handle fragile materials or parts in varying sizes and shapes.

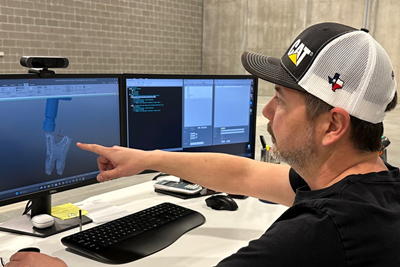

Read MoreDigital Transparency in Machining Key to Multi-Site Additive Manufacturing

Cumberland Additive’s CNC programmer in Pennsylvania spends most of his time writing programs for machine tools in Texas.

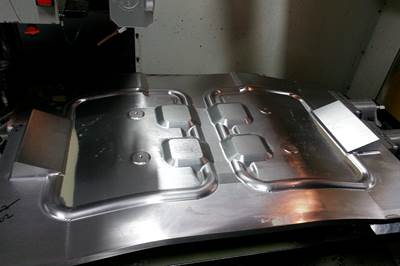

Read MoreShoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreProtecting Your Automation Investments

Shops need to look at their people, processes and technology to get the most of out their automation systems.

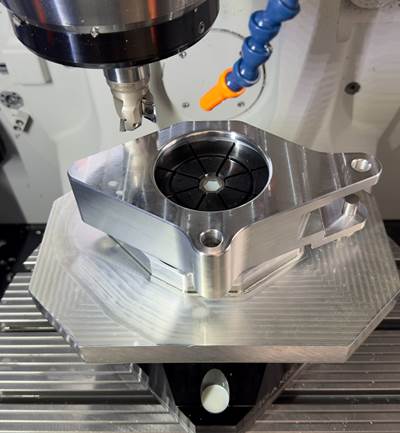

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

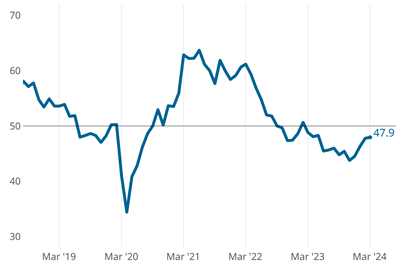

Read MoreMetalworking Activity Holds Steady in March

Overall metalworking activity leveled off in March, but not to a point of concern.

Read More

.png;maxWidth=300;quality=90)