CGTech

9000 Research Dr.

Irvine, CA 92618 US

949-753-1050

cgtech.com

About CGTech

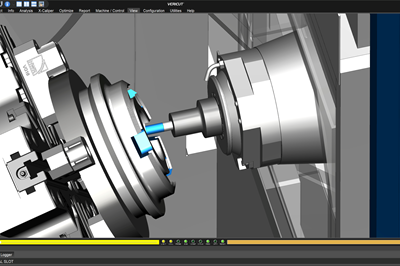

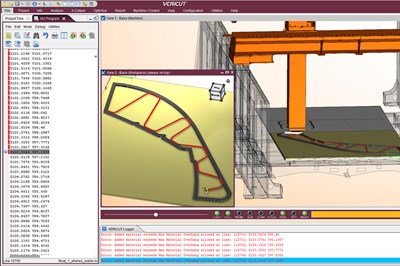

CGTech specializes in NC/CNC simulation, verification, optimization, and analysis software for manufacturing. Since 1988 CGTech’s product, VERICUT® software, has become the industry standard for simulating CNC machining in order to detect errors, potential collisions, or areas of inefficiency.

IS THIS YOUR COMPANY?

Video Gallery

Tech Tip: Axis Priority Settings

For more information please visit https://cgtech.com/

Tech Tip: Variables

For more information please visit https://cgtech.com/

What’s New in VERICUT 9.4 – CNC Machine Connect

As a result of the Scytec/CGTech partnership, VERICUT can connect to CNC machines via Scytec's DataXchange software.

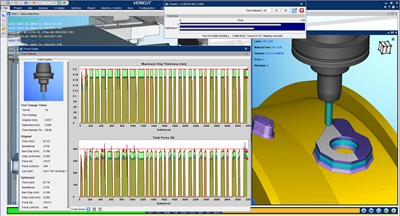

What's New in VERICUT 9.4 - Streamlined Optimization

All VERICUT users, even those without the Force module, benefit from the enhancements to optimization in VERICUT 9.4.

As Seen On Modern Machine Shop

CGTech Supplies the Following Products

Trade Names Offered by CGTech

- VERICUT®

- OptiPath®

- AUTO-DIFF™

- Force™

- CGTech®