OMAX Corporation

21409 72nd Ave. S

Kent, WA 98032-1944 US

800-838-0343 | 253-872-2300

omax.com

IS THIS YOUR COMPANY?

Video Gallery

Kakade Laser Uses OMAX Waterjets To Increase Cutting Capabilities | OMAX Customer Success Story

Learn more here, today: https://www.omax.com/en/us/build-your-waterjet-business Kakade Laser uses OMAX waterjets to ...

The Cutting Floor S1E1 Barton Talks Abrasives

Welcome to The Cutting Floor, a new series where we talk to experts in the waterjet world about all things waterjet. To start off the ...

Adapting Files for Waterjet

Our demolab team programs and cuts an model of the Golden Gate Bridge. The original file was designed to be cut out of wood ...

5 Axis Cutting Demo

Using 5-axis cutting, our OMAX demolab team programs and cuts the northern half of the globe.

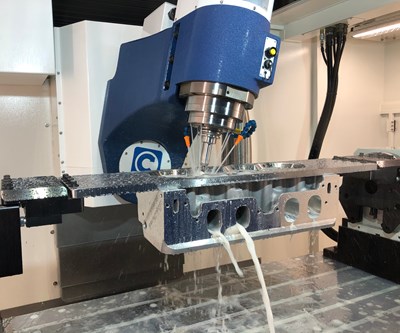

As Seen On Modern Machine Shop

OMAX Corporation Supplies the Following Products

Trade Names Offered by OMAX Corporation

- Intelli-CAM®

- MAXJET®5

- MAXIEM® JetMachining® Centers

- GlobalMAX

- OMAX® JetMachining® Center

- A-Jet® Cutting Head

- MAXJET®5i Nozzle

- MAXIEM®

- MAXJET®

- Intelli-VISOR®

- OMAX®

- Tilt-A-Jet® Cutting Head

- Intelli-MAX®

- ProtoMAX

- GlobalMAX

- EnduroMAX® Direct Drive Pumps

- Intelli-TRAX®

- Intelli-ETCH®

- Intelli-TRACE®

- OptiMAX