ESSENTIAL READING

VIEW ALLHow to Evaluate Measurement Uncertainty

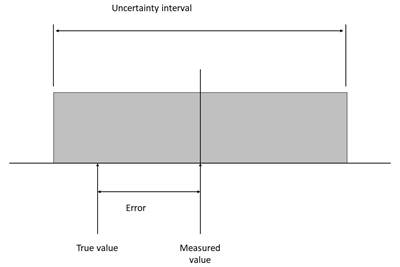

Manufacturing and measurement are closely coupled. An important consideration for the use of measurement results is the associated measurement uncertainty. This article describes common metrology terms and provides an example uncertainty analysis.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreHow to Choose the Correct Fixed-Body Plug Gaging Solution

The two types of fixed-body plug gages are both accurate, fast and easy to use. Consider these factors when selecting one for your gaging application.

Read MoreRethink Quality Control to Increase Productivity, Decrease Scrap

Verifying parts is essential to documenting quality, and there are a few best practices that can make the quality control process more efficient.

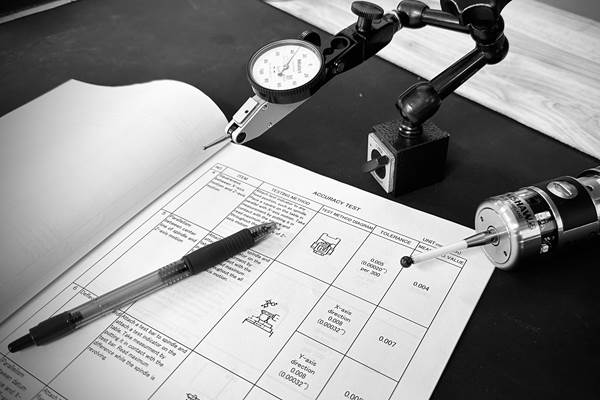

Read MoreHow to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

Read MoreHow to Choose the Correct Measuring Tool for Any Application

There are many options to choose from when deciding on a dimensional measurement tool. Consider these application-based factors when selecting a measurement solution.

Read MoreLatest Measurement News And Updates

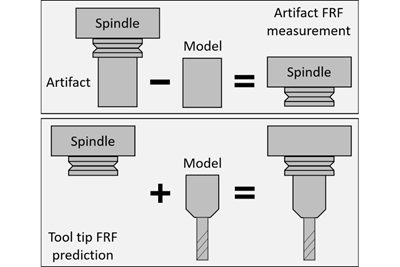

Using Digital Tap Testing to Measure Machining Dynamics

Tool-toolholder-spindle-machine combinations each have a unique vibration response. We can measure the response by tap testing, but we can also model it.

Read MoreMore Surface Finish Parameters at Hand

Measuring surface finish at the point of manufacture is often done by the same machinist who is manufacturing the part. They need tools that meet test requirements and are easy to use.

Read MoreNew Scale Robotics Partners With FANUC to Automate Manual Gaging

This new partnership will enable the automation of manual gaging processes, helping manufacturers eliminate bottlenecks and improve productivity.

Read MoreThe Nuts and Bolts for Getting the Gaging Fixtures Right

Gage fixtures are the key to accurate and repeatable measurements, so make sure there is no play at its joints.

Read MoreZeiss Software Increases 3D Measurement Data Compatibility

Zeiss has launched Zeiss Inspect, a system-independent data evaluation for optical and CT measurement data.

Read MoreVerisurf Announces Software-Integrated CMM Sales Platform

The platforms enables customers to source new and pre-owned CMMs powered by Verisurf software.

Read MoreFeatured Posts

Digital Comparators are More Than Just Readout Devices

Modern digital comparators often combine the performance of touchscreen phones, LVDTs, digital amplifiers and even small PCs into the size of a standard dial indicator.

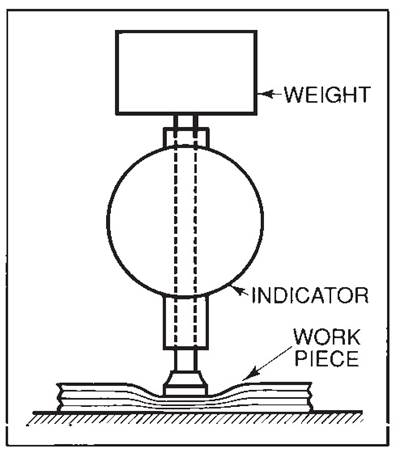

Read MoreThe Many Ways of Measuring Thickness

While it may seem to be a straightforward check, there are many approaches to measuring thickness that are determined by the requirements of the part.

Read MoreHow to Evaluate Measurement Uncertainty

Manufacturing and measurement are closely coupled. An important consideration for the use of measurement results is the associated measurement uncertainty. This article describes common metrology terms and provides an example uncertainty analysis.

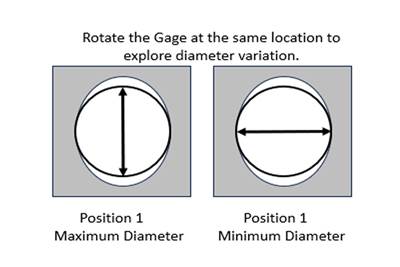

Read MoreTips for Anticipating Hole Conditions

When measuring an ID with an indicating plug gage, it is OK to slow down to learn more about the hole being measured and explore for extraneous conditions.

Read MoreMarposs Celebrates its Past, Eyes Future Opportunities

During its open house in Auburn Hills, Michigan, Marposs presentations focused on future opportunities across growing industries such as EV and semiconductors.

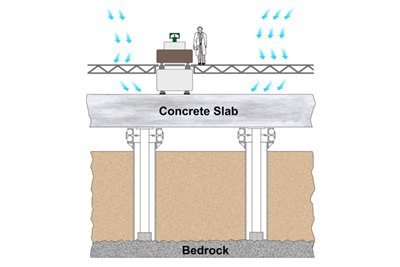

WatchConsiderations for Adding CMM Capabilities to Your Shop

CMMs may provide simple efficiency gains, but if you look deeper, the machine unlocks more complex work for your shop.

Read MoreFAQ: Measurement

What is a caliper?

Calipers, which can be Vernier, dial or digital, are versatile tools for basic length measurement. They can be used on the shop floor, in the inspection room or even in the home by hobbyists.

Source: Caliper Tips And Tricks

What is a micrometer?

A micrometer consists of two opposing surfaces, a stationary anvil and a moveable spindle. On most micrometers, these hardened steel or carbide-tipped contact surfaces are flat. However, micrometers can also be equipped with contact tips with unique forms for measuring special part characteristics.

Convenience is one of the reasons the micrometer is often the tool of choice for length/diameter measurements. The basic micrometer provides direct size information quickly, has high resolution and is easily adaptable to many different measurement applications.

What is a gauge?

Gages are indirect reading instruments. The measurement units live not on the scale but off-site (for example, in a calibration room), and a master or other standard object acts as their substitute. The workpiece is compared against the master and only indirectly against the measurement units. The gage thus evaluates not the dimension itself, but the difference between the mastered dimension and the workpiece dimension. Examples of these comparative gages include an adjustable bore gage, mechanical snap gages or bench stands with dial indicators.

Gages tend to be faster and more accurate than measuring instruments. This is because they are dedicated to a particular size, and over their short range, they produce higher resolution and hence, greater accuracy.

What does CMM mean?

A coordinate measuring machine (CMM) is a measurement tool that consists of a motion system, a probing system, a computer and measurement software.

Source: Machining 101: What Are Coordinate Measuring Machines?

Measurement Supplier Categories

- Flatness Measuring Equipment

- Gages, Mechanical

- Laser Measurement Systems

- Calibration Equipment

- Comparators, Optical & Other

- Surface Finish Measuring Equipment

- Gages, Electronic/Digital

- Coordinate Measuring Machines, Portable

- Coordinate Measuring Machines (CMMs)

- Data Collection Devices for Gaging, SPC, etc.

- Roundness Measuring Equipment

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)