Managing Change in a CNC Machine Shop

The practice of continuous improvement in machine shops should be ongoing. But is there a tipping point at which constant change becomes counterproductive?

I’ve been dealing with a lot of change lately, personally as well as professionally. Individually, none of these changes is anywhere close to drastic, extreme or for the worse. They are things that pretty much everyone must deal with at some point. But the cumulative effect is wearing on me. Constant change seems to be my new normal, at least for the moment.

That said, I’m a proponent of continuous improvement (i.e. change) in our industry, and I have visited and written about a number of machine shops in which change has become second nature. It’s what they do to grow their businesses and become more efficient.

How do you keep continuous improvement in check so as not to overwhelm your employees?

Yet, I’ve been led to ponder how machine shop owners and managers manage change. How do you keep continuous improvement in check so as not to overwhelm your employees? How can you tell if too many aspects of your operation are simultaneously changing at too fast a pace?

I posed these questions to those who follow me on LinkedIn. Miles Free, interim director of the Precision Machined Products Association (PMPA), points to the second derivative. “Rate of change of the rate of change. When all of the change piles up into one big collision, our performers lose their bearings. Our best shops try to implement changes in planned cycles so that they are directing the orchestra rather than pulling people from the wreckage.”

Tracy Ellis, regional sales manager of machine tool supplier SW North America, replied in agreement. “In machine tool lingo, we call the second derivative ‘jerk.’ Too much can literally cause a machine tool to lose its bearings. With a machine tool, we try to develop a nice bell-shaped curve that gives enough acceleration to move quickly and precisely. I think machine shop owners and managers must to consider the frequency of change and the amplitude (amount of change) — making the right decisions at the right time — to put themselves in a competitive position.”

During a recent conversation about this with Kylan Hastreiter, the vice president of Hastreiter Industries says the key to implementing change starts with hiring people who are open to new ideas, not those with a “this is how we’ve always done it” mindset. But communication between management and employees is just as important. Employees must know that changes in technology or processes are being made to make them more efficient at their jobs, which, in turn, makes the entire operation more efficient. It also should be made clear that such changes can lead to new opportunities for them. Even if they excel at and are valued for their current talents, they don’t have to be stuck in the same position for their entire career.

What’s your take? Have you been in a situation in which too much was changing too fast at your shop? What affect did it have on your employees and overall operation? What advice might you provide to your peers? Shoot me an email reply to my LinkedIn post. I’d appreciate your input.

Read Next

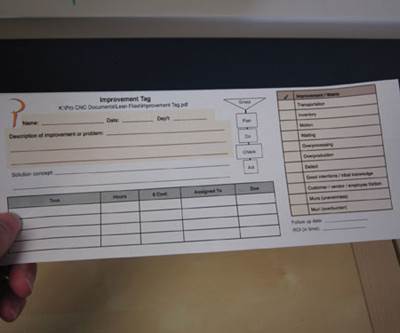

Committed to Kaizen

This shop has made a strong commitment to kaizen, so much so that it devotes five percent of company time to continuous improvement activities. This has led to multiple ideas that have enabled the shop to become more efficient and effective.

Read MoreHow to Continuously Improve Your Machine Shop

Monthly Kaizen events could help your company improve operations in 12 ways.

Read MoreSeeing Lean

A Northwestern shop has made a strong commitment to kaizen, so much so that it devotes 5 percent of company time to continuous improvement activities. This has led to multiple ideas that have enabled the shop to become more efficient and effective.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)