Power Skiving Enables Smaller, Precise Robotics Machining

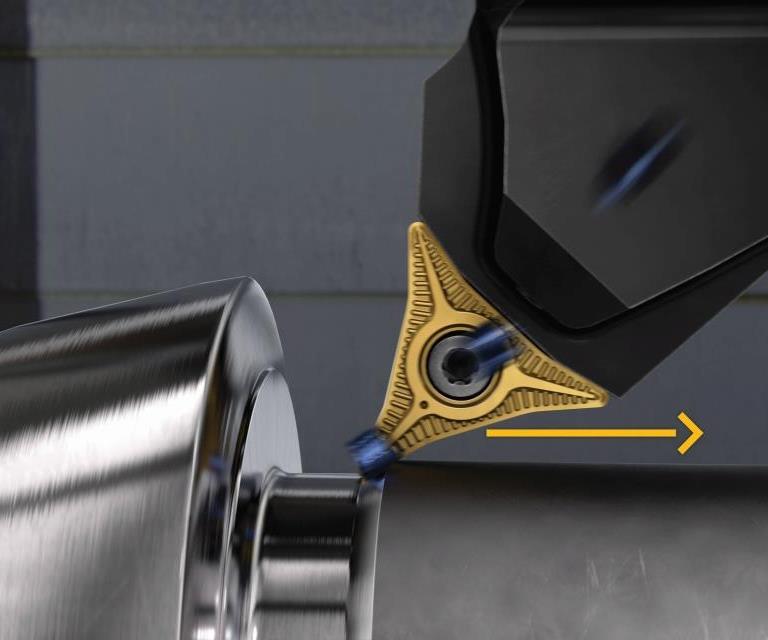

Power skiving tools like Sandvik Coromant’s CoroMill 178 can increase productivity, precision and flexibility when machining gears for applications such as industrial robotics.

Sandvik Coromant’s power skiving tools, now a tried-and-tested solution for automotive gear production, double as an effective solution for robotics gear manufacturing.

Photo Credit: Sandvik Coromant

The overall number of industrial robots operating in factories worldwide grew to 2.7 million in 2019, according to the 2020 World Robotics Report by the International Federation of Robotics (IFR). This was a 12% increase from 2018 and a historic high. Robots now factor into a range of industries, from automotive and aerospace to the food industry and pharmaceuticals — yet all of these sectors have common requirements.

Today’s industrial robots must not only fit into increasingly small spaces, dedicating as much “manufacturing real estate” as possible to production, but also be lighter with reduced inertia and the ability to perform more exact movements with optimal speed and efficiency. This places pressure on manufacturers to machine smaller and more precisely engineered components with increased design flexibility.

Manufacturers must cost-effectively meet these requirements while maximizing machine uptime and reducing cycle times. Scenarios like the ongoing COVID-19 pandemic also introduce challenges to the shop floor, such as unpredictable demand and the need to maintain productivity with fewer workers at any one time.

In the face of all these challenges, Sandvik Coromant recommends looking to power skiving, which has particularly benefited gear manufacturing in the automotive industry, and recommends its PrimeTurning concept.

By combining hobbing and shaping, power skiving enables manufacturers to use a single, multitasking machine to combine what would have been several operations on specialized machines. This change increases machine utilization — as well as gross profit margins.

Photo Credit: Sandvik Coromant

What is Power Skiving?

Power skiving is a continuous rotary cutting technique where the tool meshes with the gear under production. The intersecting angle between the tool and gear axis affects the revolution speed and greatly benefits productivity. As the process combines hobbing and shaping, power skiving enables machining of a whole component in a single, multi-tasking machine rather than several machines. A single set-up greatly improves machine utilization and total profit — based on Sandvik Coromant’s own findings, a 20% increase in machine utilization can provide a 10% higher gross profit margin. Manufacturers can also benefit from increased design precision and flexibility.

One Sandvik Coromant customer in the automotive segment achieved a 90% reduction in machining time through the use of power skiving tools. In that case, the customer reduced the time-consuming shaping process it was using to make gear components from low-alloy 16MnCr5 by opting for Sandvik Coromant’s CoroMill 178 for power skiving. Harish Maniyoor, Sandvik Coromant global product manager for automotive, says the customer reported increased process stability and considerably improved component quality.

Power Skiving for Robotics

In another case, a robotics manufacturer in Korea approached Sandvik Coromant for assistance producing an internal gear reducer the manufacturer would use for precise motion control in one of its robots.

One Sandvik Coromant customer in the automotive segment achieved a 90% reduction in machining time through the use of power skiving tools.

The customer’s existing production setup took up to 60 minutes to machine a single part. Sandvik Coromant’s power skiving solution, which the customer used in an NTX 1000 machining center from DMG Mori, boosted productivity enough that each component took only eight minutes to machine.

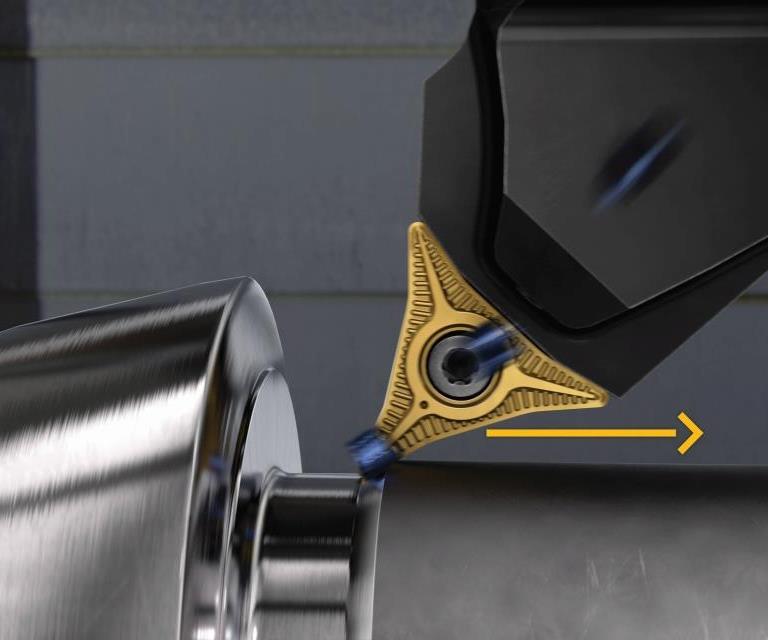

Prime-Time PrimeTurning

In addition to its power skiving tools, Sandvik Coromant says its PrimeTurning process will also benefit manufacturers requiring more precise engineering for robotic components.

PrimeTurning technology enables machine shops to complete longitudinal (forward and back), facing and profiling operations with a single tool. The methodology is based on the tool entering the component at the chuck and removing material as it travels towards the end of the component. This prioritizes metal removal rates and results in faster, quality production and changeovers.

Related Content

Zero-Adjustment Bar Pullers Simplify Turning Automation

Spring-loaded grippers and adjustable programming are enabling bar pullers to fulfill their promise to save time and money in CNC turning automation.

Read MoreBuying a Lathe: The Basics

Lathes represent some of the oldest machining technology, but it’s still helpful to remember the basics when considering the purchase of a new turning machine.

Read MoreKaast Machine Tools Updates Dual-Spindle Lathe

The A-Turn SYMCNC Dual-Spindle Lathe is now available in four different swing lengths, including 22.5", 24", 26.75" or 36".

Read MoreChoosing Your Carbide Grade: A Guide

Without an international standard for designating carbide grades or application ranges, users must rely on relative judgments and background knowledge for success.

Read MoreRead Next

A New Turning Process Enables Cutting “In Reverse”

A methodology for cutting in both directions on a CNC lathe promises to make turning a much more productive operation in certain applications. New types of inserts driven by new CAM tool paths are key enablers of this development, but implementing the whole multifaceted system as a system is essential.

Read MoreClosed-Loop Gear Production

A familiar concept is now gaining serious traction, enabling manufacturers to develop closed-loop cells that automatically match the finished product to design concept goals.

Read More

.png;maxWidth=300;quality=90)