A New Turning Process Enables Cutting “In Reverse”

A methodology for cutting in both directions on a CNC lathe promises to make turning a much more productive operation in certain applications. New types of inserts driven by new CAM tool paths are key enablers of this development, but implementing the whole multifaceted system as a system is essential.

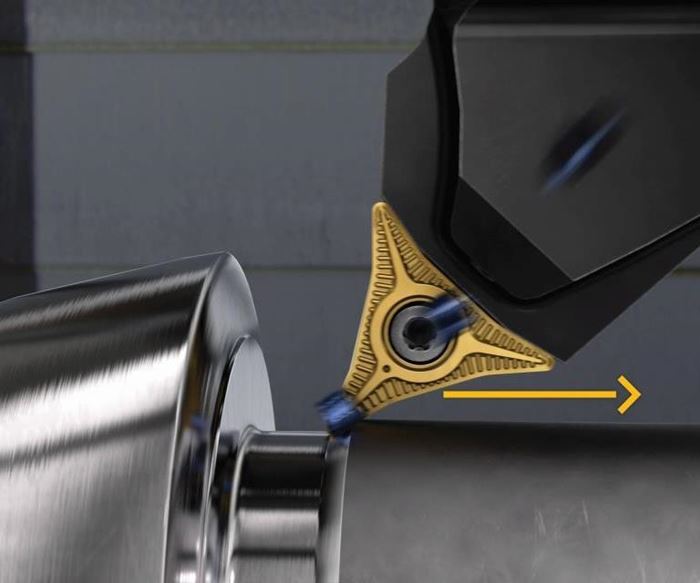

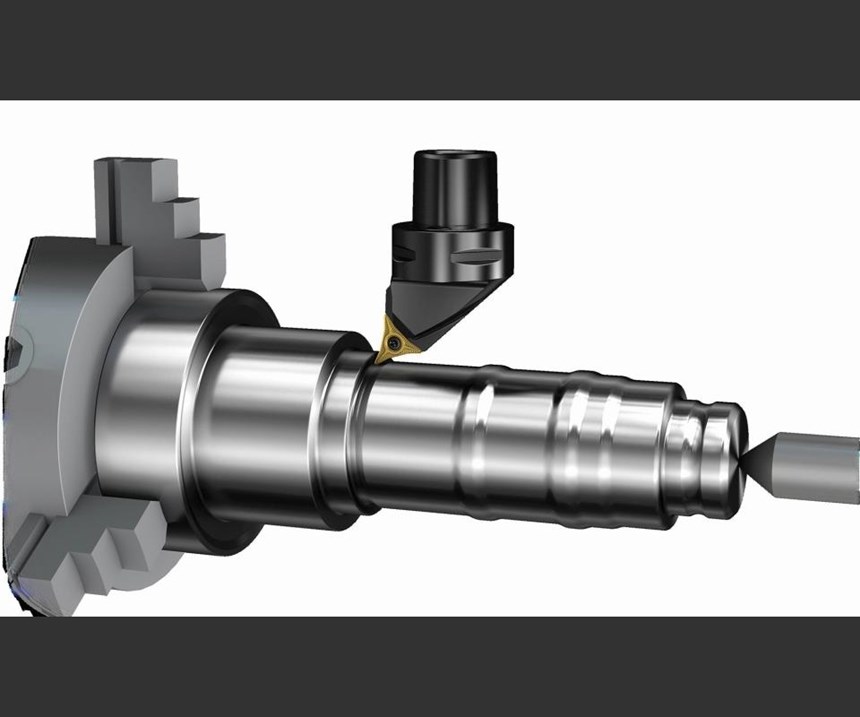

Without a prior explanation, an observer of a live turning demonstration might declare that the tool in the demo lathe is cutting in the wrong direction, exactly opposite of the usual practice. Likewise, the viewer watching a video of this demo might strongly suspect that the recording was being played in reverse. That would account for what seems to be the “backward” motion of the turning tool. A rendering of the tool motion in these demos, as shown at the top of this article, indicates that the direction of the cutting tool is actually following the yellow arrow. This direction is clearly the opposite of a normal or traditional turning operation. What is going on here?

Sandvik Coromant Inc., the inventor of this process, calls this new turning concept PrimeTurning, which uses dedicated CoroTurn Prime tooling. In fact, the two current styles of inserts for PrimeTurning (one for light machining and one for heavy machining) are designed to cut in a direction that is opposite of the usual approach. In addition to moving toward the chuck in the Z axis as they cut, these tools can also “go in reverse” and move away from the chuck as they cut. Likewise, when needed, these tools can cut “up from” or “down to” the part centerline in the X axis for facing or shoulder cutting. Each insert is capable of roughing, finishing or profiling by cutting in either direction when there is an advantage.

For the right applications, the company claims that the results are astonishing: as much as an 80-percent boost in productivity. As much as twice the tool life for the inserts. Significantly smoother surface finishes.

How can cutting in the “wrong” direction be so right for certain operations in these applications? A detailed answer to this question is worthwhile, because it involves a number of insights into the nature of the basic turning process itself. Based on these insights, the concept of PrimeTurning seems to upend normal practice, and do so on several levels.

Apparently, a turning capability like this has never been possible before. The geometry of the light-machining and heavy-machining insert styles appears to be entirely new. Both styles are

highly specialized; the multi-angled nose of the heavy-machining insert is particularly different in a striking way. In addition, new capabilities in CAM software had to be developed to streamline programming of the unprecedented tool paths and dynamic feed rates required for this turning process. (Mastercam - CNC Software, Inc. has been working in tandem with Sandvik to create the needed algorithms so the cutting concepts can be readily applied by end users.) The way coolant is delivered to the cutting zone is also new. (As one might imagine, chip formation and heat transfer occur in unexpected patterns, so coolant plays a critical role in the process.) Other details such as modified toolholders and strict setup requirements must also be attended to for this process to obtain its maximum benefit.

This is a lot to take in. Of course, Sandvik Coromant recognizes that the market for PrimeTurning will require considerable “re-education” to understand and implement the radical aspects of the process correctly. However, the company has been conducting numerous tests in the field with a range of selected customers around the world. Reports from these test users indicate that, once they get the hang of the process and establish the discipline it calls for, they will be clamoring for more access to these tools, the company says.

Cory Koch, an application engineer at Hartwig Inc., a machinery dealer in Houston, Texas, and one of the first machining facilities to take a close look at PrimeTurning, says, “These tools will change the way our customers process their parts, allowing better tool life, much higher material-removal rates and the ability to maintain tighter tolerances. The tools are so versatile in their design that you must think outside of the box to imagine what is possible.”

When Tool Designers Are Turned Loose

The origin of PrimeTurning and the corresponding CoroTurn Prime inserts goes back several years to events in Sandvik Coromant’s development center in Sweden. The company attributes the pioneering efforts to Adam Johansson, a young engineer who joined its R&D department in 2012, and Ronnie Löf, a 20-year veteran in cutting tool engineering there. One account of their collaboration begins with a note that typical descriptions of turning involve a non-rotary tool removing material as it travels from the end of a rotating component towards the chuck. Conventional wisdom confirms that, in this method, the smaller the lead angle between the cutting edge and the feed direction, the greater the opportunity to increase the feed rate and gain higher productivity. The problem is, a small lead angle prevents the cutting edge from reaching the start of a shoulder, and it also creates long, curved chips that are difficult to control. This relationship between lead angle and limited productivity seemed an unalterable “given” for turning operations.

However, when the two engineers started discussing the lead angle/reach dilemma in late 2012, they approached it with a shared curiosity and the courage to challenge accepted truths, or so the story is told. They recall that before long, a small, far-fetched seed started to cultivate, and the discussions became more intense. Their idea was simply to turn backward, from the chuck to the end of the component. This would immediately solve the challenge of reaching the shoulder with a small lead angle.

“The metalcutting industry has been removing metal from end to shoulder for centuries. Every turning expert can line up impressive amounts of arguments to why the opposite is completely unrealistic,” Mr. Johansson says. He cites chip control as the main counter argument, as the small lead angle still creates long, curved chips, regardless of the turning direction. Mr. Johansson and Mr. Löf set out to solve the issue together with two other equally open-minded designers, Joe Truong and Krister Wikblad. Their research seemed to promise success. When product manager Håkan Ericksson became involved in 2015, the team intensified its discussions with colleagues, key customers and other stakeholders and began testing the concept on a larger scale.

These tests, which the company says included extensive trials and experiments in its own labs as well as applications in end-user plants, raised and then helped resolve numerous technical issues. When PrimeTurning was officially announced to the industry in April 2017, Sandvik Coromant had a clearly defined concept and a complete methodology to present, along with practical guidelines for when and where this development had the most to offer. The main benefits, according to the company, are these:

- Aggressive cutting parameters for increased output of components and reduced cost per component.

- Consistent tool wear that leads to improved machine utilization, fewer tool changes and reduced costs.

- Chip control and long tool life that give more predictability in long-running jobs, which means fewer production holdups.

- Reduced temperature at the cutting edge, which improves tool life.

Turning Attention to Insert Details

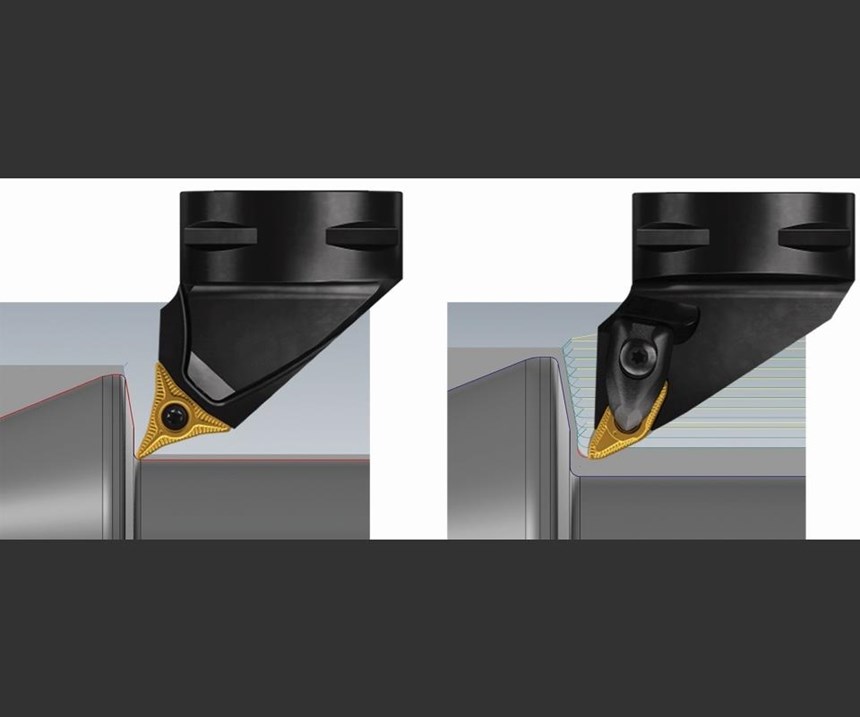

As noted, two styles of inserts are currently offered for the PrimeTurning methodology. These are designated CoroTurn Prime A and B, as shown side by side in the illustration at the top of this article. The A-type insert features three 35-degree corners and is designed for light roughing, finishing and profiling, while the B-type insert is designed specifically for heavy roughing and has what the company characterizes as two, ultra-strong corners. Nine sizes of the A type are available; six sizes of the B type. These are all non-ISO inserts, meaning simply that their geometry does not fit any of the general insert shapes defined and codable by the international standard for classifying metalcutting insert types.

It is also important to note that both types are described as “all-directional turning solutions.” In other words, either type can cut conventionally from the part end toward the chuck as on a shaft secured by a tailstock. Either type can also cut conventionally on a shoulder or a face, moving from the periphery of the part toward (down to) the center. What’s new is that either type can also cut in the opposite direction, that is, entering the part at the chuck and removing material as it travels toward the end of the shaft while the nose of the insert is still facing the chuck. (In fact, holding this orientation is what makes the operation appear backward or to be going in reverse). Likewise, for a shoulder, the face of a flange or similar “vertical” feature, either type can cut up and away from the part center. The nose of the insert still faces the chuck in the same orientation as it does when going down in conventional turning, but this does not look as startlingly strange as the horizontal/longitudinal backward cutting mode.

Because the CoroTurn Prime inserts can cut in all directions, switching from roughing to finishing, for example, does not require a tool change. Instead, the direction of the cut changes. And because the cutting direction can change, the tool does not have to retract from the workpiece surface and return to its starting point in the air to begin another pass. Under certain conditions, inserts can literally cut back and forth or up and down in consecutive passes. (Keep in mind, of course, that cutting parameters must change each time to suit the new cutting direction.)

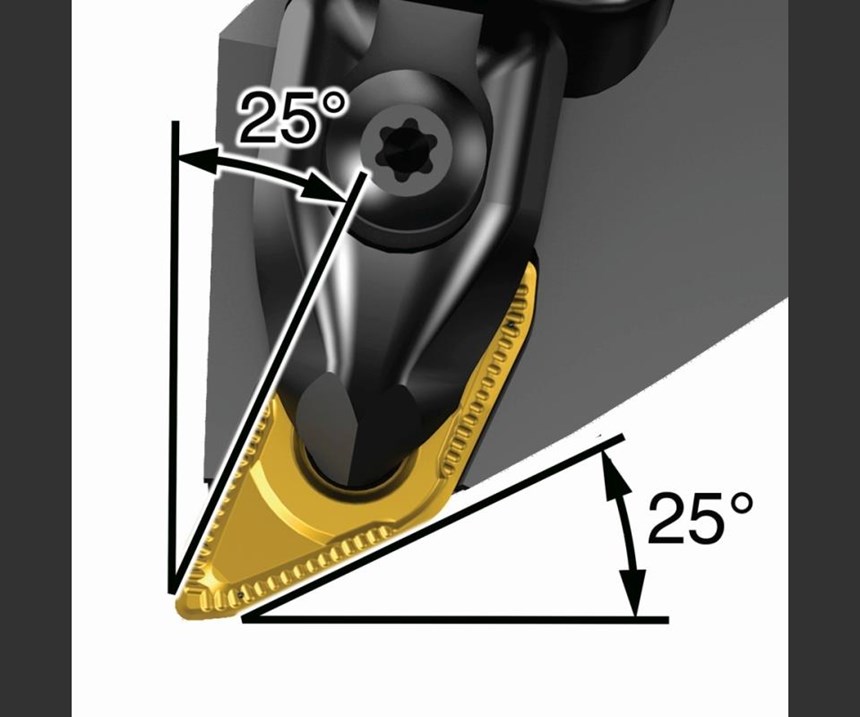

What’s happening when a CoroTurn Prime insert is cutting backward is easiest to grasp with the B-type insert. By entering the workpiece at the chuck and removing material as it travels toward the tailstock, it is possible to apply a small entering angle (30 degrees for the A type; 25 for the B) and a high lead angle. This approach spreads cutting forces and frictional heat over a larger area of the insert’s cutting surface than is possible cutting conventionally. It also creates thinner, wider chips that do not concentrate rubbing contact (and resultant heat) on the nose radius at the insert’s tip. The thin, wide chips can be controlled by the bumpy ridges of the chipbreaker texture, thus avoiding swarf in the form of long strands of tightly curled material.

These favorable cutting conditions, the company says, enable the application to benefit from an advantageous trade-off between more aggressive cutting parameters for productivity and prolonged, more predictable tool life. In other words, an operation can remove more material faster or have the insert last longer. In addition, whereas conventional cutting toward a shoulder can cause the insert to jam chips into the corner where the workpiece diameter changes, with PrimeTurning, cutting action occurs in a direction away from the shoulder. Chip jamming cannot happen as a result.

In the illustration at the top of this article, you might notice that the B-type insert features an irregularly angled profile such that on each side of the insert the cutting edge has a wide angle past the nose, but then trails away at a narrower angle toward the center of the insert. This gives the tip of the insert a kind of distinctive shovel shape. This design is said to maximize the strength of the cutting edges, as well as create a wiper effect where the nose radius begins to broaden.

In roughing cuts, when removing material quickly is the primary goal, this wiper effect gives the remaining stock a smooth surface, thus making finishing cuts more efficient. A better surface finish in roughing and more efficiency in finishing is a double boost to productivity for the PrimeTurning methodology, the company says. When cutting conventionally, the radius at the nose of the insert enables it to perform much like a standard turning insert, though with conventional results as well.

The A-type insert, which is designed for light- and medium-duty roughing, finishing, and fine profiling, represents a miniature version of the same tip and cutting edge geometry that is more easily seen on the larger B-type insert. The benefits of a smaller entering angle, high lead angle and manageable chip shape are enjoyed equally well for the A-type insert.

However, successfully applying the CoroTurn Prime inserts of both types is dependent on certain critical nuances in the cutting strategy of the CNC tool path. A discussion of these nuances rounds out a basic explanation of what these insert styles are capable of.

Programming Is Not a Turnoff

In recent years, CAM software developers have come up with streamlined techniques for programming highly efficient milling routines for pocketing and profiling. As Sandvik Coromant developers realized early in the testing of this new turning concept, programming the required moves for all-directional turning would be a challenge. They also recognized that optimizing this new process with advanced CAM capability was an opportunity for benefits not unlike recent programming advances such as constant-chip-load techniques for milling.

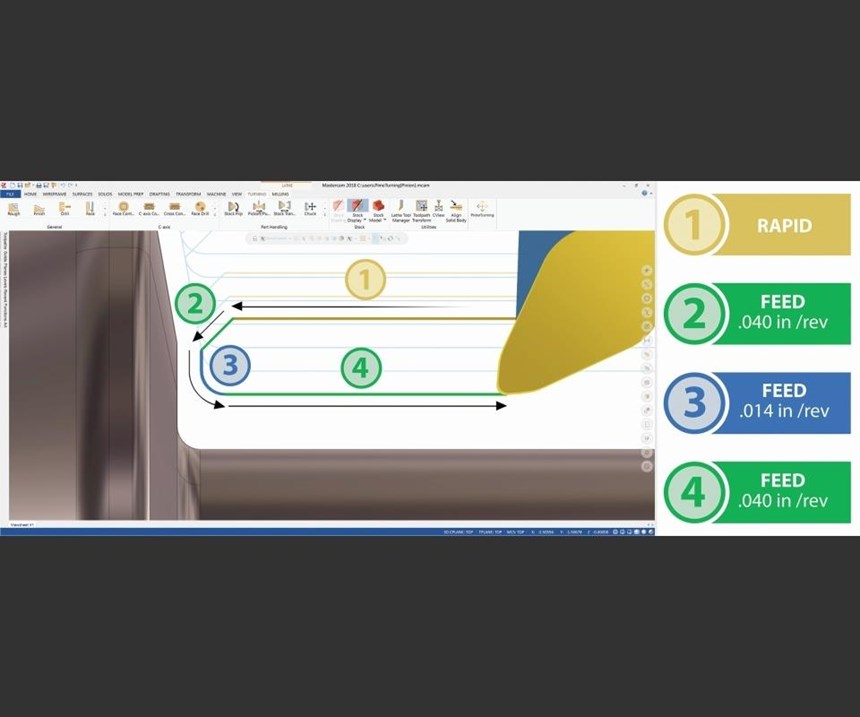

“Until now, turning utilities and CAM packages did not provide for the directional changes called for in PrimeTurning,” Mr. Ericksson says. “This process also requires provisions for entry and lead angles, as well as creating tool paths to gently arc into the workpiece and then ramp up to the appropriately higher speeds, feeds and depth of cuts that give PrimeTurning its potential.”

In 2016, Sandvik Coromant invited CNC Software, developers of Mastercam CAD/CAM software, to be a partner in the development of programming software to accommodate PrimeTurning requirements. According to Mastercam Product Director Dave Boucher, his company’s experience with the software’s Dynamic Turning and Dynamic Motion features, which involve counter-intuitive cutter motions, was expected to be useful in the novel thinking that PrimeTurning called for.

To be fair, Sandvik Coromant will make the technology for this process available to all interested CAD/CAM developers and is offering its own PrimeTurning Code Generator. This is a dedicated software utility that supports the process by generating generic ISO code compatible with CNC machines that accept this input format. It is available as a cloud-based application through an annual subscription. That said, Mastercam’s new set of turning strategies to support this process is available now as part of the 2018 release of Mastercam. (By agreement, Mastercam has an exclusive right to use this technology until November 1, 2017.) Because these strategies are likely to indicate how other CAM software developers will follow, looking at Mastercam’s insights and approach are handy here.

For example, automated capability is essential. When the user opens the PrimeTurning Properties window, tabbed pages solicit entry of all required values, selections and options for the tool path to be generated. For example, choice of strategy is based on the shape of the part. For shaft-like parts, the programmer would likely choose “horizontal.” To turn a flange, “vertical” would be appropriate. Each strategy selection brings up the corresponding diagram of cutter moves, along with boxes for entering values for the associated variables. Using this input, the software automatically does all the calculations and toolpath generation necessary for applying this turning methodology.

For example, when the CoroTurn Prime insert feeds into the part at the chuck, its entry must include a reduced feed rate and a slight arc in the tool path where it engages the workpiece at the correct depth to cut longitudinally (backward, that is, toward the tailstock). This enables the insert to engage the material gently, and then ramp up to full speeds and feeds. The precise motion is apparent in the image from Mastercam at the top of this article.

All of the Mastercam strategies follow the rules established by Sandvik Coromant for the PrimeTurning process. Starting values for the variables related to each insert type and cutting strategy are pre-populated with recommendations from the cutting tool manufacturer. These values are suitable for workpiece materials most likely to be candidates for the PrimeTurning methodology. These include ISO P steels, ISO M stainless steels and ISO S heat-resistant superalloys. These rules also enable the software to recognize when the selected strategy and entered values call for conventional turning routines in the “normal direction” where appropriate instead of the PrimeTurning approach.

“The whole intent of Mastercam’s support for PrimeTurning is to streamline the application of the methodology and assist users to obtain the 50- to 80-percent gain in metal-removal rates and doubled tool life that is the potential for this process,” Mr. Boucher says.

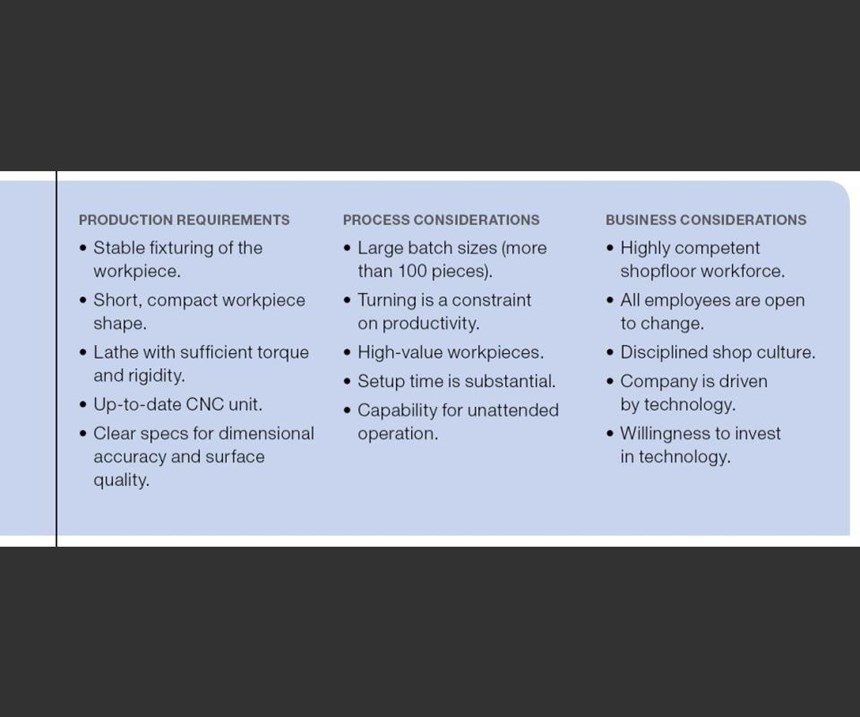

End Users Take a Turn

Sandvik Coromant has been forthright in saying that PrimeTurning is “not for everyone.” Although the company sees a wide expansion of applications in the future, the current methodology and dedicated insert types will be most attractive to a particular class of users. The table in the slideshow at the top of this article summarizes the conditions that will compel such potential users to apply this methodology.

“Large-batch manufacturers are most likely to see the greatest cost-per-part savings, especially if turning is a production bottleneck,” Mr. Ericksson says. “The method requires stable components and a rigid setup due to the increased radial forces. This means that conventional turning may still be appropriate for vibration-prone portions of slender components.” He adds that PrimeTurning is best-suited for short and compact workpieces and shafts for which a tailstock is available. It is a good choice for mass production as well as for components that require frequent setups and tool changes. He also expects it to be applied initially to expensive or high-value workpieces.

Mr. Ericksson stresses that users must be committed to the PrimeTurning methodology as a multifaceted system that should be implemented in its entirety. Otherwise, the full benefits are less likely be to be achieved, he says. “The profile of a PrimeTurning user is emerging as a shop that is highly competent in existing applications, is open to change and new ideas, has a culture of shopfloor discipline in place, and is willing to invest in technology.”

This last point deserves an added note. CoroTurn Prime inserts are premium-priced offerings, although anticipated returns make them an exceptional value, Mr. Ericksson believes. In addition to these dedicated inserts, special toolholders are also required. At the moment, the company offers 52 variants of toolholder styles that accept A- or B-style inserts, including Coromant Capto, CoroTurn QS and square-shank styles. Holders for A-type inserts have a TR-style locking interface for stability. Holders for B-type inserts have a shim-protected tip seat for added strength.

Toolholders for CoroTurn Prime inserts have multiple orifices to direct internally-fed coolant to cutting edges. These high-pressure streams are intended to help control heat and aid in chip evacuation, the company says. Coolant application is especially important for the A-type insert, because the tip at each corner is not as massive as the B-type, so its ability to absorb heat and resist wear is somewhat lower. For this reason, A-type insert holders have one coolant jet aimed at the top of the insert as well as two from the sides.

A user’s investment in this total methodology can be justified by the results, Mr. Ericksson says. For example, he points out that the overall productivity gains from adopting this turning concept may enable a production shop to defer an investment in a new machine tool if an increase in capacity is anticipated.

Has Metalworking Turned a Corner?

It can be argued that, in recent years, productivity gains in turning operations on CNC lathes have not seen the same level of advancement as that experienced in milling operations on CNC machining centers. This seems attributable to the fact that turning primarily involves a “single-point” process. In most cases, only one cutting edge on the turning tool is removing material from a single workpiece in the lathe at a time, whereas milling usually involves cutting tools with multiple edges, such as multi-flute round tools or milling heads with multiple inserts. Machining centers have also benefited from options for rapid pallet changes and multiple part setups on pedestal fixtures in horizontal machines. Combining turning with other machining processes on turn-mill or multitasking machines has been a significant source of overall part-making efficiency, but metal removal rates in the turning portions of a part program for such equipment have remained relatively unchanged.

Mr. Ericksson believes that PrimeTurning is a significant departure from the status quo in metal removal rates for turning. “The initial reaction from users testing this technology indicates that the prospect of a 50-percent gain in productivity will be a game-changer for most turning operations. Adopting this approach is not without its challenges, but the motivation to do so is compelling,” he says.

More important, however, is what he predicts will be a spate of new developments in turning technology. “PrimeTurning brings to the foreground a synergy among tooling capability, machining capability, programming capability and even workforce capability,” he says. He adds that, once machine designers, cutting tool manufacturers, software developers and end-user application engineers begin opening their minds to the new possibilities, surprising innovations are likely to follow.

He notes that the digitally connected environment that is rapidly emerging in shops and plants around the world due to the rise of the Industrial Internet of Things and initiatives such as Industry 4.0 will accelerate and magnify the effect of these changes. In the meantime, he says that Sandvik Coromant has a timetable of projects to expand the PrimeTurning concept with additional CoroTurn Prime inserts. “We believe our current offerings only scratch the surface of all-directional turning possibilities,” he says.

Global patents on the PrimeTurning concept and technology are expected to be finalized in mid-2018.

Related Content

New Machining Technology Works With Old to Restore WWII Submarine

A set of donated boring bars that can be used in a 1954 boring head will enable volunteer machinists to recreate a pair of binoculars for the USS Pampanito.

Read MoreChoosing Your Carbide Grade: A Guide

Without an international standard for designating carbide grades or application ranges, users must rely on relative judgments and background knowledge for success.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreA New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)