Wastewater Treatment: Why Companies Should Care and What They Can Do About It

Shops and plants should be concerned about wastewater treatment for many reasons, and the best way to turn genuine concern into effective solutions starts with an awareness of current options for wastewater-treatment equipment.

Shops and plants should be concerned about wastewater treatment, says Tim Hanna, vice president of business development for PRAB, a designer and manufacturer of wastewater recycling systems as well as engineered conveyors and equipment for processing turnings, chips and metalworking fluids. Companies also should be aware of current options for wastewater-treatment equipment because upgrading a system may be the best way to turn genuine concern into effective solutions.

Wastewater treatment has become an increasingly critical part of plant operations over the last decade, Mr. Hanna says. Shops and plants must remain compliant with tightening wastewater treatment, handling and disposal regulations, as well as the Clean Water Act, the Resource Conservation and Recovery Act and the Safe Drinking Water Act. State and local municipalities have several additional standards that companies must adhere to as well.

He notes other reasons to recycle wastewater, such as improving a company’s working environment, employee morale and public image, as well as adhering to ISO 14001 initiatives. These efforts promote “green” operation by prioritizing environmental awareness, he says.

This is a bottom-line issue as well, Mr. Hanna points out. Companies should care about wastewater treatment and reuse because it enables them to cut operational costs and increase profitability. The goal should be to recycle coolant, wash water and other fluids internally to increase tool life, improve product quality, reduce maintenance and prolong the usage of working fluids. When the time comes to finally dispose of the fluids, companies have a smaller volume to get rid of, or a concentrated stream they can treat themselves for lower-cost handling by public water-treatment plants.

According to Mr. Hanna, the first step is to know and understand the types of wastewater equipment that are available. He outlines seven common types of wastewater equipment, what they do and how they can benefit a business:

Ultrafiltration Systems

Ultrafiltration (UF) is a pressure-driven process that uses a membrane to remove emulsified oils, metal hydroxides, emulsions, dispersed material, suspended solids, and other large, molecular-weight materials from wastewater, coolant and other solutions. UF excels at the clarification of solutions containing suspended solids, bacteria, and high concentrations of macromolecules, including oil and water.

UF systems are designed to reduce oily water volumes by as much as 98 percent without the use of chemical additives. They are also capable of removing small fines in deburring and tumbling operations to enable the water and soap solution to be recycled and reused. Companies can also see a benefit from the reduction in the cost of wash water and detergents by as much as 75 percent, when calculating both heating and disposal costs. For waste disposal, they can achieve as much as a 90-percent reduction in haul-away costs. For these reasons, UF membrane technology is quickly becoming the process of choice over conventional filtration methods, Mr. Hanna says.

Vacuum Evaporation and Distillation

Evaporation is a natural phenomenon and a clean separation technology, recognized as a best available technique in several wastewater-treatment processes. It is distinct from other separation processes in that it removes the water from the contaminants rather than filtering the contaminants from the water.

Vacuum evaporators are available to accelerate the natural evaporation process to treat and distill industrial wastewater amounts from 1 to 120 tons per day. They can achieve residual total solids concentrations of more than 85 percent. According to PRAB, no other technology can attain such high water-recovery and concentration rates.

The three primary types of vacuum evaporators are:

- Heat pumps – These are designed to be flexible and versatile with low electrical-energy consumption and superior reliability.

- Hot/cold water – They use existing, excess hot water/steam and cooling water to reduce operating costs.

- Mechanical vapor recompression – They use large wastewater flow rates with low boiling temperatures to reduce energy consumption

Reverse Osmosis Systems

Reverse osmosis (RO) is a technology that removes dissolved solids and impurities from water using a semi-permeable RO membrane, which allows the passage of water but leaves the majority of dissolved solids/salts and other contaminants behind. The RO membranes require water to be under high pressure, greater than osmotic pressure, to do this. The water that passes through the RO membrane is called the permeate, and the dissolved salts that are rejected by the RO membrane are called the concentrate.

A properly designed and operated RO system can remove as much as 99.5 percent of incoming dissolved salts and impurities plus virtually all colloidal and suspended matter from the most challenging waste and feed water applications, Mr. Hanna says. Typically for industrial, metalworking and surface-treatment applications, RO technology is the final process after ultrafiltration or the chemical treatment of waste and feed water.

Paper Bed Filters

These types of filters use gravity and disposable paper media or permanent filter media to produce a positive barrier that removes solids from all free-flowing industrial process liquids. Paper bed filters are suitable for applications involving low to medium stock removal of ferrous and nonferrous metals, as well as organic and inorganic contaminants such as glass, rubber and plastic. They extend coolant and tool life by an average of 27 percent, as well as increase surface-finish quality.

Standard paper bed filtration units are available with or without magnetic separation and can accommodate flow rates ranging to 130 gallons per minute with different classes of filter media allowing for adjustments of micron clarity. Drum-type models occupy one-third the floor space as their paper-bed counterparts and can process as much as 500 gallons per minute of fluids.

Solid Bowl Centrifuges

These units use centrifugal force instead of consumable media to separate solids from liquids in metal-processing applications in which removal of fines is important to recycle, and for reuse goals. Process liquid is either pumped or gravity-fed to the centrifuge inlet. Process solids are then centrifugally separated from the liquid phase and collected in an easily removable rotor, also known as a liner. Clarified liquid overflows the rotor into the outer case and is returned by gravity to the process, which minimizes the cost of hauling waste coolants and water away from the facility.

Solid bowl centrifuges provide high-performance liquid/solid separation for virtually all types of particles (metallic and non-metallic, ferrous and nonferrous) and are available in both manually cleaned rotor style with a reusable liner and fully automatic self-cleaning designs.

Tramp Oil Separators

In this type of wastewater-treatment equipment, contaminated fluid flows through a series of baffles and a porous media bed where free and mechanically dispersed oils are separated from the fluid. The clarified fluid then flows over the effluent discharge weir back to the reservoir for reuse. The collected oils, inverted emulsions, etc., are collected at the top of the separator and automatically discharged into a suitable receptacle.

Using gravity flow and coalescence, this type of separator can reduce tramp oils to less than 1 percent in a single pass and use no consumable products. It can also:

- Reduce new fluid purchase costs by as much as 75 percent (including synthetic and semi-synthetic coolants, soluble oils and wash waters)

- Reduce the cost of wash-water detergents, heating and disposal

- Reduce hazardous waste volumes by as much as 90 percent

- Achieve system payback (ROI) in six months or less

Vacuum Filters

This type of filtration system, capable of continuous operation to eliminate downtime, is virtually maintenance-free and delivers high sludge-volume elimination, resulting in lower production costs. Disposable-media vacuum filters utilize a vacuum chamber to draw contaminated coolant through the disposable-filter media and apply the proven principle of optimal filtration through contaminate, or sludge build-up, forming a filter cake on the media. These units are available with flow rates ranging to 2,000 gallons per minute.

Semi-permanent vacuum filters further reduce operation costs by eliminating the need for disposable media. Back flushing the filter with clean coolant keeps the filter clean without requiring large volumes of air. The back-flushed solids drop from the filter element and settle into a tank where they are removed via a chain dragout/flight arrangement. These units require minimal floor space and are completely self-contained, simplifying maintenance and operation.

Mr. Hanna concludes that in today’s world, there are many available options that make it possible for companies to do the right thing with their wastewater, both environmentally and from a business perspective.

Related Content

Rego-Fix Toolholding System Reduces Coolant Consumption

MQL PG collets are designed for machines using one-channel, internal through-spindle MQL systems.

Read MoreJorgensen's Coolant Collection System Eliminates Sludge Build-Up

The PermaClean system adds agitation to the coolant collection system or holding tank and prevents particulates from settling.

Read MoreHigh-Speed Videos Analyze Machining Processes in Fine Detail

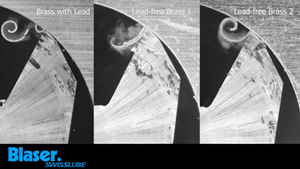

Blaser Swisslube captures the machining process, chip formation and behavior of its Synergy 735 metalworking fluid through high-speed, macro photos and videos.

Read MoreSTLE To Host Metalworking Fluid Management Program

STLE’s program is a two-and-a-half-day education program offering a comprehensive overview of metalworking fluid management.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)